Production method for drug balloon

A production method and balloon technology, applied in catheters, coatings, etc., can solve the problems of low drug utilization, loose crystallization, drug loss, etc., and achieve the effect of good combination and tight arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

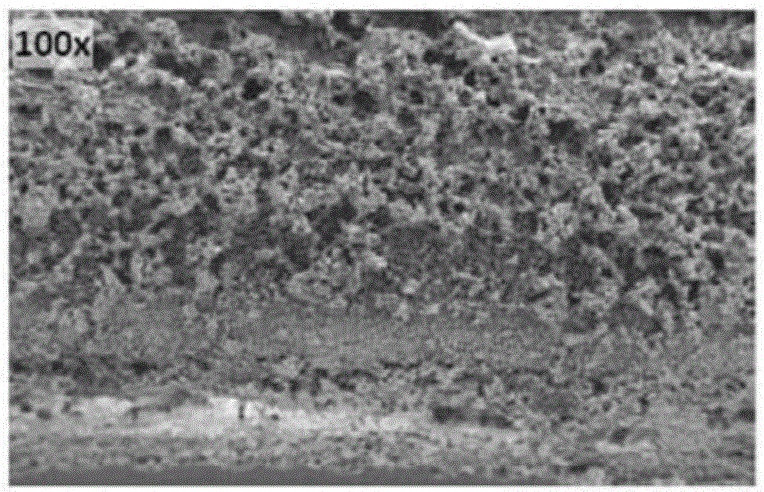

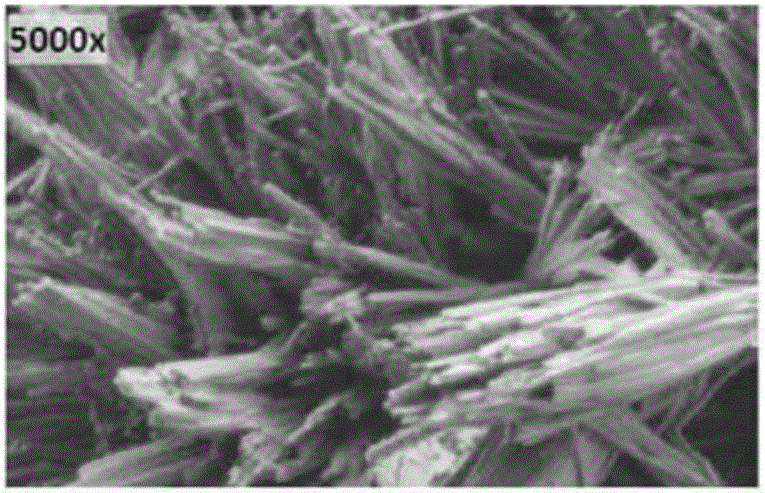

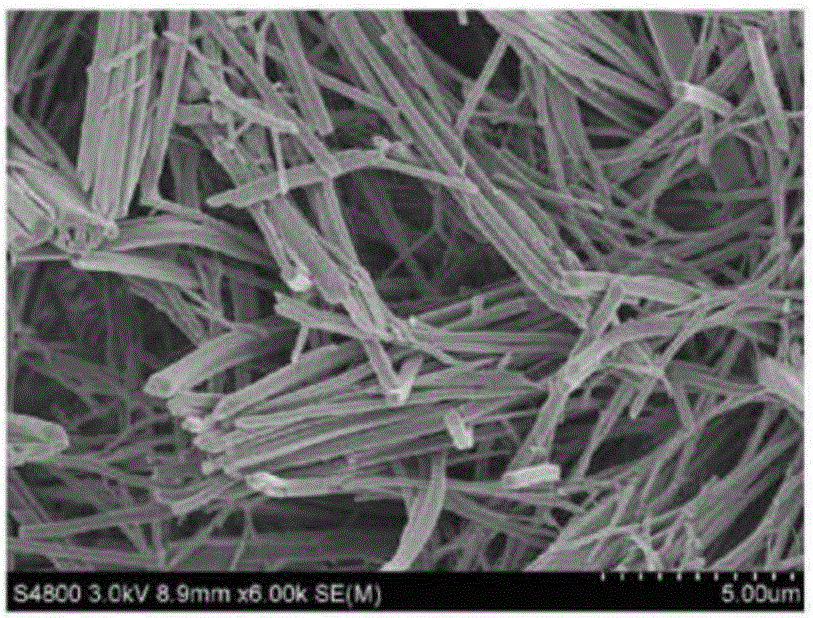

[0073] The structure of the present invention will be explained in detail below in conjunction with the accompanying drawings.

[0074] like Figure 5 to Figure 6 As shown, a method for producing a drug balloon provided in an embodiment of the present invention includes the following steps:

[0075] 1). Preparation of supersaturated drug solution:

[0076] 11). Weighing the carrier and the paclitaxel bulk drug according to the preset dose, and dissolving the paclitaxel and the carrier in an organic solvent to obtain a drug solution with a certain concentration. The ratio of carrier to paclitaxel is 0.5-1.5:1, preferably 0.8-1.0:1. The organic solvent may be one or more of ethanol, methanol, acetone, isopropanol, methyl vinyl ketone, dimethyl sulfoxide, ethyl acetate, acetonitrile, tetrahydrofuran, and the like. Ultrasonic dissolution in an ultrasonic cleaning machine for 10 minutes to 30 minutes until the drug solution is colorless and transparent.

[0077] 12). Add a pred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com