High-barrier puncture-resistant irradiation crosslinking type multilayer heat shrinkage film and preparation method thereof

A heat-shrinkable film and puncture-resistant technology, which is applied in the packaging field, can solve the problem that the puncture-resistant effect cannot meet the needs of food packaging with sharp angles, and achieve good oxygen barrier performance, good oxygen barrier performance, and strong deformation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

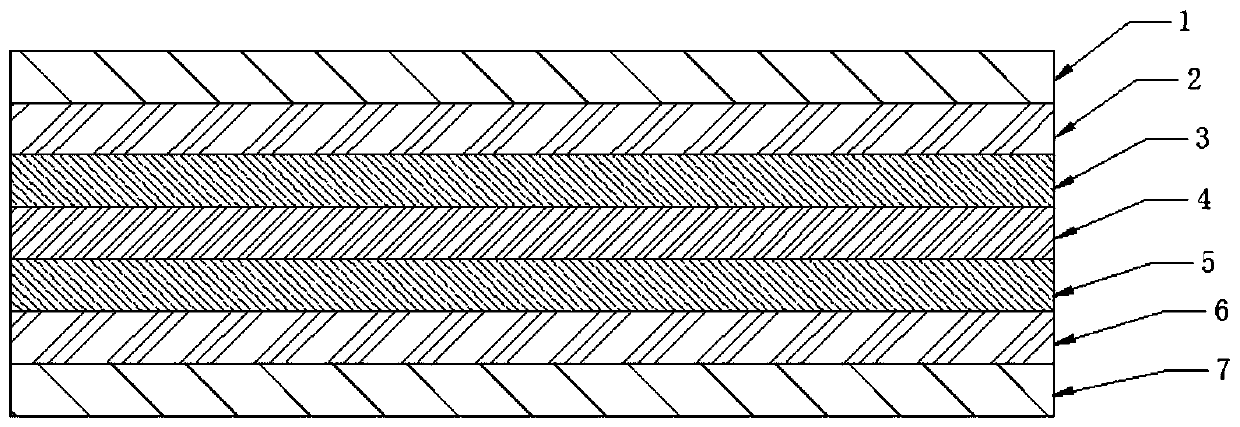

[0032] A high-barrier, puncture-resistant, radiation-crosslinked multilayer heat-shrinkable film, comprising a co-extruded first PE film layer 1, a first adhesive film layer 2, a first PA film layer 3, an intermediate EVOH film layer 4, The second PA film layer 5, the second adhesive film layer 6 and the second PE film layer 7;

[0033] The total thickness of the heat-shrinkable film is 200 μm, wherein the thickness of the first PE film layer is 80 μm, the thickness of the first adhesive film layer is 4 μm, the thickness of the first PA film layer is 10 μm, and the thickness of the EVOH film layer is 12 μm. The thickness of the PA film layer is 10 μm, the thickness of the second adhesive film layer is 4 μm, and the thickness of the second PE film layer is 80 μm.

[0034] (1) Multi-layer co-extrusion blown film: the first PE film layer or the second PE film layer, mix the polyethylene raw materials and put them into the hopper of the extruder, melt them at 200-220°C, and enter ...

Embodiment 2

[0041] The difference between embodiment 2 and embodiment 1 is:

[0042] A high-barrier, puncture-resistant, radiation-crosslinked multilayer heat-shrinkable film, the total thickness of the heat-shrinkable film is 200 μm, wherein the thickness of the first PE film layer is 40 μm, the thickness of the first adhesive film layer is 20 μm, and the first The thickness of the PA film layer is 30 μm, the thickness of the EVOH film layer is 20 μm, the thickness of the second PA film layer is 30 μm, the thickness of the second adhesive film layer is 20 μm, and the thickness of the second PE film layer is 40 μm.

[0043] (1) Multi-layer co-extrusion blown film: the first PE film layer or the second PE film layer, mix the polyethylene raw materials and put them into the hopper of the extruder, melt them at 200-220°C, and enter the die; the first For the adhesive film layer or the second adhesive film layer, add maleic anhydride-modified polyethylene into the hopper of the extruder, melt...

Embodiment 3

[0050] The difference between embodiment 3 and embodiment 1 is:

[0051] A high-barrier, puncture-resistant, radiation-crosslinked multilayer heat-shrinkable film, the total thickness of the heat-shrinkable film is 100 μm, wherein the thickness of the first PE film layer is 30 μm, the thickness of the first adhesive film layer is 5 μm, and the first The thickness of the PA film layer is 10 μm, the thickness of the EVOH film layer is 10 μm, the thickness of the second PA film layer is 10 μm, the thickness of the second adhesive film layer is 5 μm, and the thickness of the second PE film layer is 30 μm.

[0052] (1) Multi-layer co-extrusion blown film: the first PE film layer or the second PE film layer, mix the polyethylene raw materials and put them into the hopper of the extruder, melt them at 200-220°C, and enter the die; the first For the adhesive film layer or the second adhesive film layer, add maleic anhydride-modified polyethylene into the hopper of the extruder, melt i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com