Multilayer heat-shrinkable film and containers fitted with labels made from the film through heat shrinkage

A technology of heat shrinkage and film application in the direction of instruments, layered products, identification devices, etc., which can solve surface heat resistance, adhesion resistance, poor lubricity, film adhesion, inner surface heat resistance, adhesion resistance and poor lubricity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

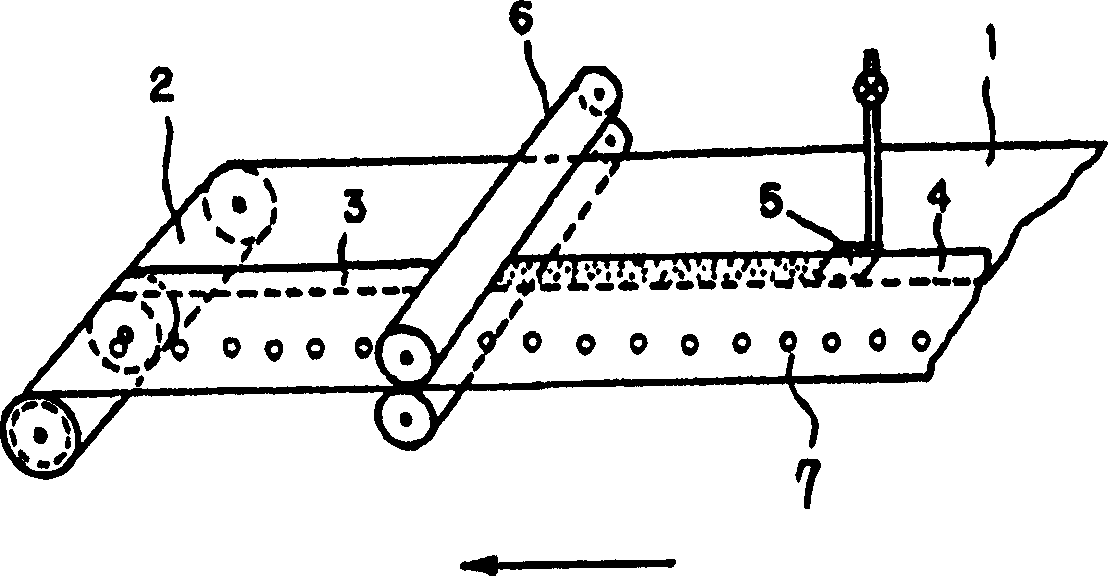

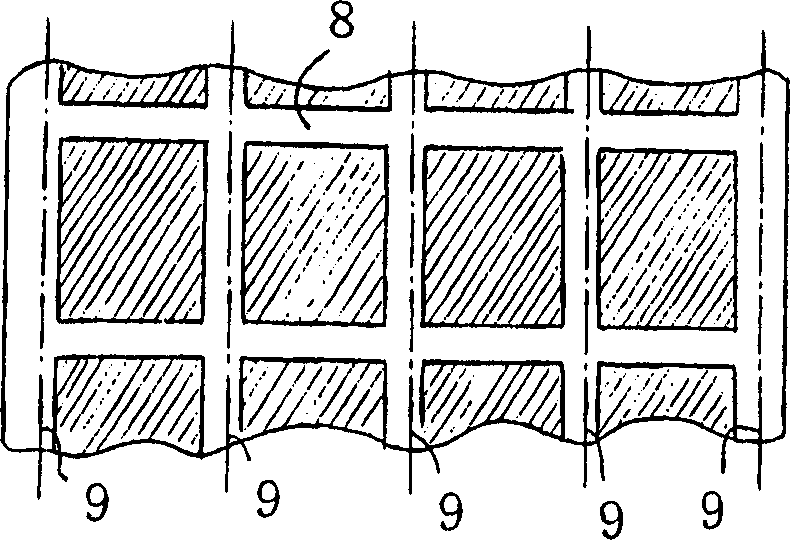

Method used

Image

Examples

Embodiment 1

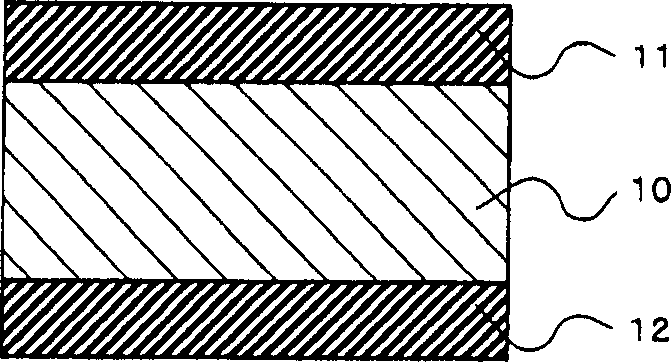

[0093] The resin composition for forming the inner and outer film layers (68% by mass of a random copolymer of ethylene and cyclic olefin (APEL8009T, manufactured by Mitsui Chemicals Co., Ltd.), 31% by mass of a pass metal containing 1-hexene as a copolymerization component) was prepared. The linear low density polyethylene of the metallocene catalyst system formed by the polymerization of the locene catalyst (Mitsui Chemicals Co., Ltd.'s EOPOLY-SP2320), 1 mass% of EOPOLY-SP2320 as the base resin and containing 10 mass% of synthetic silica. master batch), and a resin composition for forming an intermediate film layer (72% by mass of a propylene-ethylene random copolymer containing a petroleum resin (F239V manufactured by Mitsui Chemicals Co., Ltd.), 8% by mass of a low-crystalline ethylene- 1-Butene copolymer (Tefuma-A4085 manufactured by Mitsui Chemicals Co., Ltd.) and 20 mass % random copolymer of ethylene and cyclic olefin (APEL8009T manufactured by Mitsui Chemicals Co., Ltd...

Embodiment 2

[0096] A multilayer heat-shrinkable film was obtained in the same manner as in Example 1, except that 65 mass % of F239V, 7 mass % of Tefuma-A4085, and 28 mass % of APEL8009T were used as the intermediate layer resin composition. The transverse thermal shrinkage of the film (10 seconds in warm water at 90°C and 10 seconds in boiling water), longitudinal tear propagation strength, turbidity, gloss, transverse shrinkage stress in warm water at 90°C, and stiffness (hardness) are shown in the table. 1 shown.

Embodiment 3

[0102]Except using a mixture of 45 mass % of F239V, 5 mass % of Tefuma-A4085 and 50 mass % of the film pulverized product obtained in Comparative Example 2 (the ratio of APEL 8009T in the intermediate layer is about 12 mass %) as the intermediate layer Except for the resin composition, a multilayer heat-shrinkable film was obtained in the same manner as in Example 1. The transverse thermal shrinkage of the film (10 seconds in warm water at 90°C and 10 seconds in boiling water), longitudinal tear propagation strength, turbidity, gloss, transverse shrinkage stress in warm water at 90°C, and stiffness (hardness) are shown in the table. 1 shown.

[0103] Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com