Multi-layer co-extrusion high-temperature-resistant BOPP (biaxially-oriented polypropylene) film and preparation method thereof

A multi-layer co-extrusion, high temperature resistant technology, used in chemical instruments and methods, layered products, flat products, etc., can solve the problems of bag breakage, wrinkling, air leakage, etc. Abrasion and heat shrinkage, high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

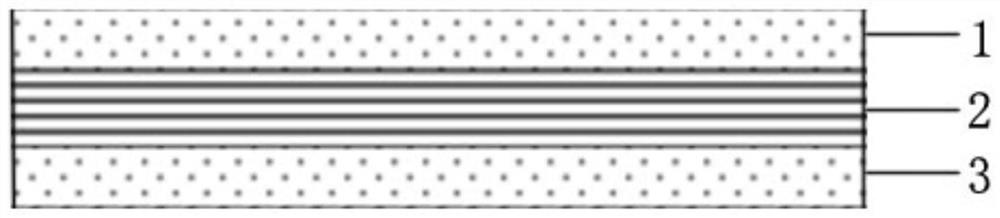

[0040] This embodiment provides a kind of multi-layer co-extruded high temperature resistant BOPP film, such as figure 1 As shown, the film sequentially includes an upper high temperature resistant layer 1, a core layer 2 and a lower high temperature resistant layer 3;

[0041] The thicknesses of the upper high temperature resistant layer 1 and the lower high temperature resistant layer 3 are independently 5 μm;

[0042] The thickness of the core layer 2 is 15 μm;

[0043] Based on the total weight of the upper high temperature resistant layer or the lower high temperature resistant layer, the raw materials of the upper high temperature resistant layer and the lower high temperature resistant layer each independently include: polyetherimide 43%, glass fiber 15%, Calcium silicate 5%, polypropylene copolymer 35%, pyromellitic dianhydride 0.6%, hydroxyethyl acrylate 0.6%, glass microspheres 0.7%, antioxidant 0.1%.

[0044] Based on the total weight of the core layer, the raw ma...

Embodiment 2

[0051] This embodiment provides a multi-layer co-extruded high temperature resistant BOPP film. The difference between this embodiment and Embodiment 1 is:

[0052] Based on the total weight of the upper high temperature resistant layer or the lower high temperature resistant layer, the raw materials of the upper high temperature resistant layer and the lower high temperature resistant layer each independently include: polyimide 30%, glass fiber 20%, silicon Calcium acid 15%, polypropylene copolymer 33%, pyromellitic dianhydride 0.6%, hydroxyethyl acrylate 0.6%, anti-glass beads 0.7%, antioxidant 0.1%.

Embodiment 3

[0054] This embodiment provides a multi-layer co-extruded high temperature resistant BOPP film. The difference between this embodiment and Embodiment 1 is:

[0055] Based on the total weight of the upper high temperature resistant layer or the lower high temperature resistant layer, the raw materials of the upper high temperature resistant layer and the lower high temperature resistant layer independently include: 55% polyvinylpyrrolidone, 5% glass fiber, silicic acid Calcium 5%, polypropylene copolymer 33%, pyromellitic dianhydride 0.5%, hydroxyethyl acrylate 0.5%, glass microspheres 0.5%, antioxidant 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com