Production process of thermal contraction two-way stretch polyamides film

A production process and transverse stretching technology, applied in the field of BOPA film production process, can solve the problems of wrinkles, affect product appearance, sales discount, etc., and achieve the effect of high thermal shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

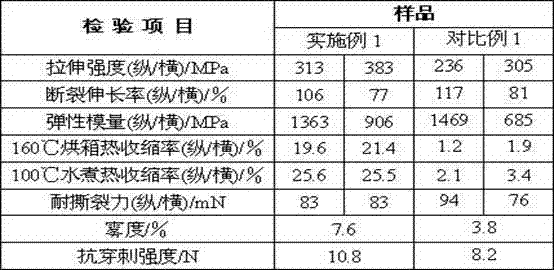

Examples

Embodiment 1

[0041] The production process of BOPA film comprises the following steps:

[0042] 1) Melt the PA masterbatch and extrude it into a film through a three-extrusion extruder. The extrusion temperature of the extruder is 255°C, and the temperature of the die head of the extruder is 235°C;

[0043] 2) Cool and form at 20-28°C to obtain crude PA film;

[0044] 3) The crude PA film is stretched longitudinally and transversely in turn, and rolled up to obtain the product.

[0045] Among them, the temperature of longitudinal stretching is 53°C, and the stretching ratio is 320%;

[0046] The heat-setting temperature in transverse stretching was 140° C., and the stretching ratio was 330%.

Embodiment 2

[0048] The production process of BOPA film comprises the following steps:

[0049] 1) Melt the PA masterbatch and extrude it into a film through a three-extrusion extruder. The extrusion temperature of the extruder is 240°C, and the temperature of the die head of the extruder is 240°C;

[0050] 2) Cool and form at 20-28°C to obtain crude PA film;

[0051] 3) The crude PA film is stretched longitudinally and transversely in turn, and rolled up to obtain the product.

[0052] Among them, the temperature of longitudinal stretching is 45°C, and the stretching ratio is 300%;

[0053] The heat-setting temperature in transverse stretching was 160° C., and the stretching ratio was 350%.

Embodiment 3

[0055] The production process of BOPA film comprises the following steps:

[0056] 1) Melt the PA masterbatch and extrude it into a film through a three-extrusion extruder. The extrusion temperature of the extruder is 270°C, and the temperature of the die head of the extruder is 240°C;

[0057] 2) Cool and form at 20-28°C to obtain crude PA film;

[0058] 3) The crude PA film is stretched longitudinally and transversely in turn, and rolled up to obtain the product.

[0059] Among them, the temperature of longitudinal stretching is 60°C, and the stretching ratio is 340%;

[0060] The heat-setting temperature in transverse stretching was 130° C., and the stretching ratio was 320%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com