Preparation method of lithium ion battery diaphragm, lithium ion battery diaphragm and lithium ion battery

A technology for lithium-ion batteries and diaphragms, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as inability to ensure that the slurry is completely consistent, troublesome adjustment of the proportion of slurry, and decreased gas permeability of the diaphragm. Large-scale industrial production, excellent uniformity and consistency, and the effect of reducing thermal shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In a first aspect, in some embodiments, a method for preparing a lithium-ion battery separator is provided, comprising the following steps:

[0039] Fix the base material in the unwinding mechanism in the vacuum reaction chamber, and feed the optional coating material plasma gas into the vacuum reaction chamber;

[0040] Vaporize the coating material into the vacuum reaction chamber by vapor deposition equipment, and deposit the coating material on the base material by vapor deposition;

[0041] The substrate material with the coating material deposited on the surface is received in the winding mechanism;

[0042] Wherein, a cooling roller is provided between the unwinding mechanism and the winding mechanism, and the cooling roller is located above the vapor deposition equipment to prevent deformation of the base material due to heat.

[0043]The preparation method of the present invention utilizes vapor deposition technology to vaporize the coating material and diffus...

Embodiment 1

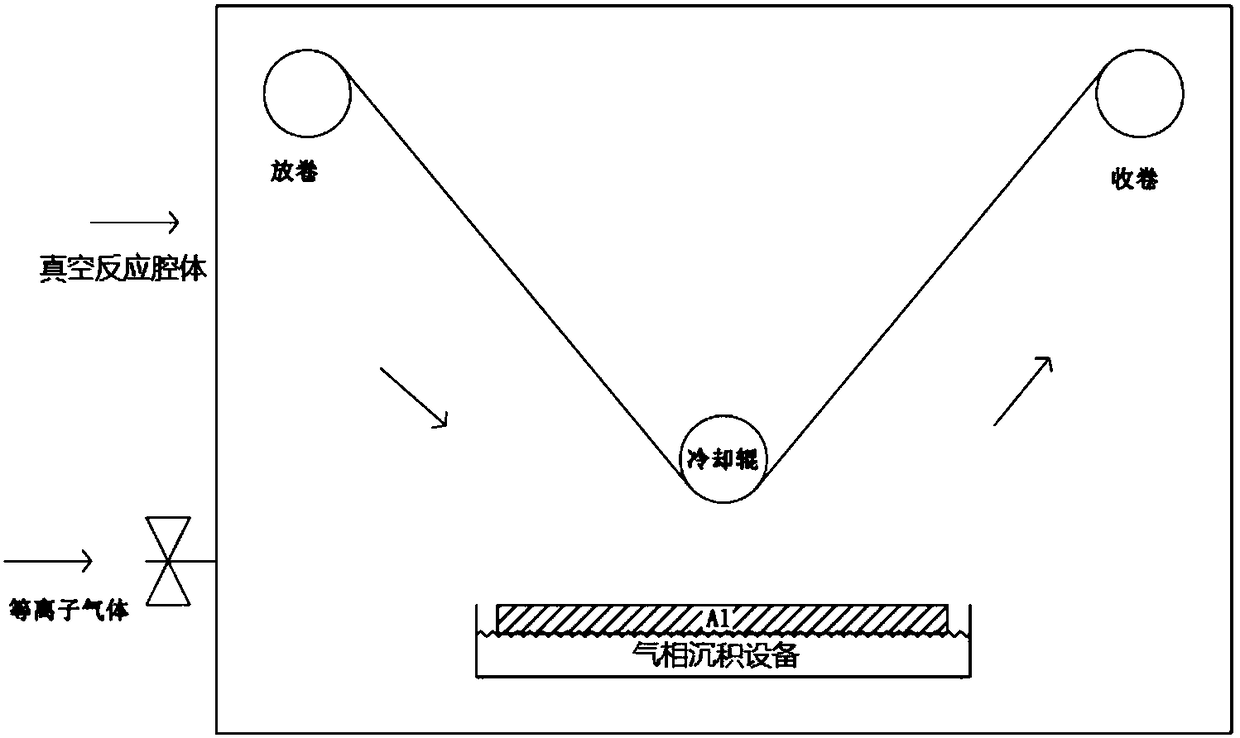

[0078] figure 1 The schematic diagram of the process flow principle of the preparation method of the lithium-ion battery diaphragm provided by the embodiment of the present invention, such as figure 1 As shown, the preparation method of the lithium-ion battery separator includes an unwinding mechanism in a vacuum reaction chamber, a cooling roller, a vapor deposition device and a winding device, wherein the cooling roller is located between the unwinding mechanism and the winding mechanism, And located directly above the vapor deposition equipment;

[0079] The process of using the above device to prepare the diaphragm includes: fixing the base material in the unwinding mechanism, feeding the optional coating material plasma gas into the vacuum reaction chamber; after adjusting a certain vacuum degree and other coating parameters, opening the unwinding mechanism And winding mechanism, according to a certain line speed for continuous coating;

[0080] The coating material is ...

Embodiment 2

[0091] A preparation method of a lithium-ion battery separator, the difference from Example 1 is:

[0092] In this embodiment, the base material is PP, and the coating material is Al 2 o 3 , the plasma gas is O 2 , the coating method adopts chemical vapor deposition (CVD);

[0093] The vacuum degree of the vacuum reaction chamber is 1×10 -3 Pa, the heating temperature is 1250°C;

[0094] The thickness of the matrix material is 12-25 μm, and the thickness of the coating is 1 nm-115 nm.

[0095] In terms of mechanical properties of the coated lithium-ion battery separator obtained in this example, the heat shrinkage rate decreased by 0.1% to 15%, and the Gurley value used to characterize the air permeability increased by 0 to 20.

[0096] In terms of electrochemical performance: the surface resistance of the separator is reduced by 4% to 20%, and the liquid retention rate of the electrolyte is increased by 20 to 40%.

[0097] Applying the lithium-ion battery separator of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com