High-safety semi-solid lithium ion battery and manufacturing method thereof

A technology of lithium-ion batteries and manufacturing methods, which is applied in the direction of electrolyte storage battery manufacturing, secondary batteries, battery pack components, etc., can solve the problems of battery life and power performance impact, uneven electrode interface, increase battery internal resistance, etc., to achieve Improve the effect of large interface resistance, reduce the amount of electrolyte, and reduce the interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] According to a specific embodiment of the present invention, the coating is gravure coating.

[0038] According to the present invention, the thickness of the mixed coating can be determined as required, preferably, the thickness of the mixed coating on one side is 2-7 μm.

[0039] Optionally, the pressure formed by the high temperature pressure is 0.05-1 MPa, and the temperature is 45-85°C.

[0040] The present invention will be described in more detail below by way of examples and comparative examples.

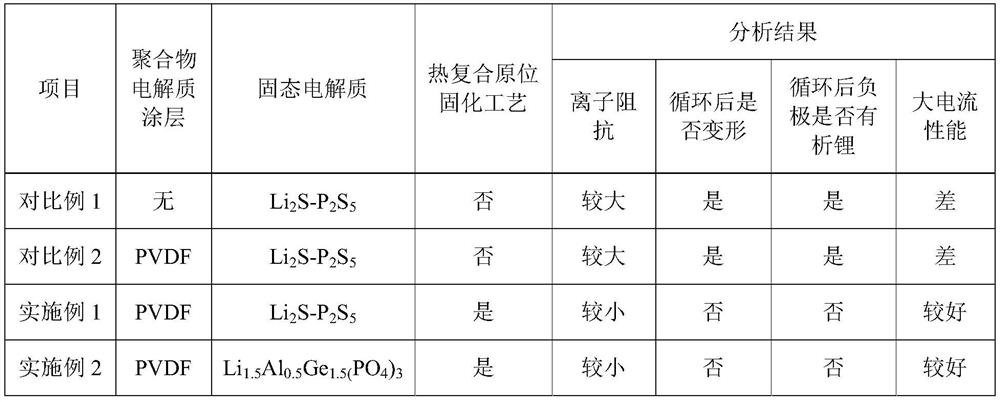

Embodiment 1

[0051] (1) Prepare a functionalized diaphragm according to step (1) of Comparative Example 2;

[0052] (2) The diaphragm and the ternary positive electrode sheet and the graphite negative electrode sheet are laminated by a lamination machine, and are packaged with an aluminum-plastic film after being connected to the lug;

[0053] (3) Inject liquid into the packaged cell, the liquid injection coefficient is 2.0g / Ah, and let the liquid injection stand for 24 hours;

[0054] (4) Then pre-charge and form the batteries, and after the formation, heat-press the batteries. The SOC of the batteries is 50%, the hot-pressing temperature is 85°C, the hot-pressing pressure is 0.6MPa, and the hot-pressing time is 20 After hot pressing, quickly put it into the normal temperature fixture and carry out cold pressing for 10 minutes;

[0055] (5) The composite battery cell is subjected to 24h aging treatment, degassing, and capacity separation to obtain a high-safety semi-solid battery.

Embodiment 2

[0057] (1) will be to the Li of step (1) in embodiment 1 2 S-P 2 S 5 Replace with Li 1.5 Al 0.5 Ge 1.5 (PO 4 ) 3 , and other parameter conditions remain unchanged, the functionalized separator is prepared;

[0058] (2) According to the steps (2)-(5) of Example 1, an integrated cell with a diaphragm and a pole piece was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com