Mechanical system of resistance type 6-inch silicon carbide single crystal furnace

A silicon carbide single crystal and mechanical system technology, which is applied in the field of mechanical systems, can solve the problems of difficulty in growing large-sized silicon carbide single crystals, low yield, etc., and achieves advantages of large-scale popularization and use, low manufacturing cost, and reduced overall growth. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings.

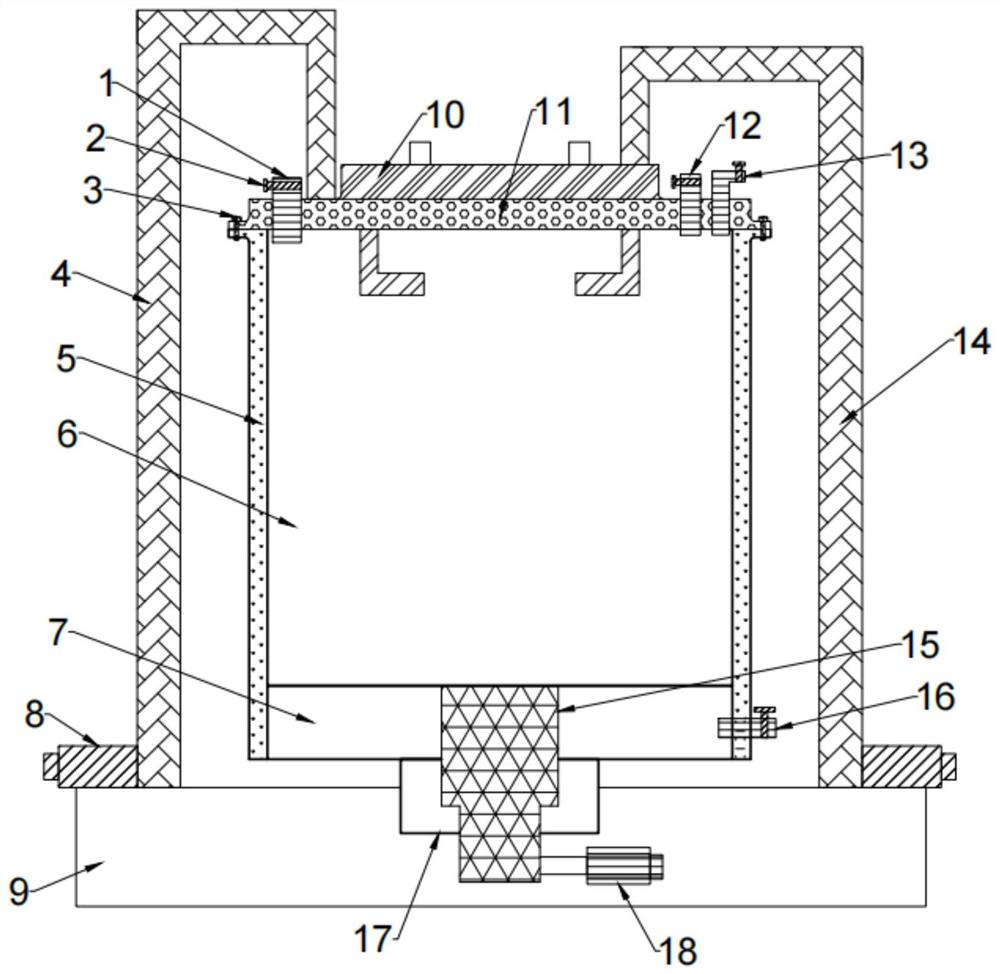

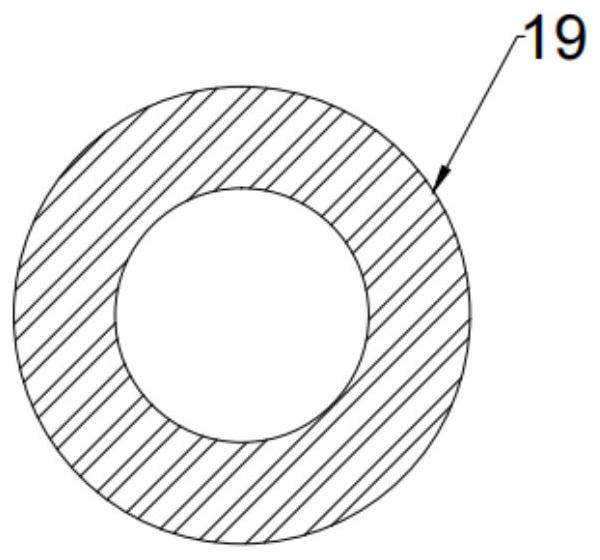

[0020] Combined with all the drawings, a mechanical system of a resistive 6-inch silicon carbide single crystal furnace. The blast cover driver 4 is disposed at the upper surface of the left and right ends of the base 9, respectively, and the top is connected to the large furnace cover 11 and the blast furnace cover 10, respectively, and the furnace body is insulated from the upper insulation chamber 6 and the bottom insulation chamber. The chamber 7 is composed, and the overall is located between the blast driver and the shot driver rack. The interlayer is provided with a circulating water system 5, and the top end is sequentially mounted. The bottom is placed in the mechanical rotary chamber 17. On the upper, the circular ring electrode 19 is in the inside of the furnace body and is placed in the lower surface of the large furnace cover, and the bottom end of the strut 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com