Non-alkali aluminium silicate glass as well as preparation method and application thereof

A technology of silicate glass and alkali aluminum, which is applied in the field of glass manufacturing, can solve the problems of unsatisfactory homogenization effect of display substrate glass, thermal stability, low thermal shrinkage rate, high elastic modulus, etc., and achieve low thermal shrinkage rate, good thermal Stability, Effect of High Elastic Modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

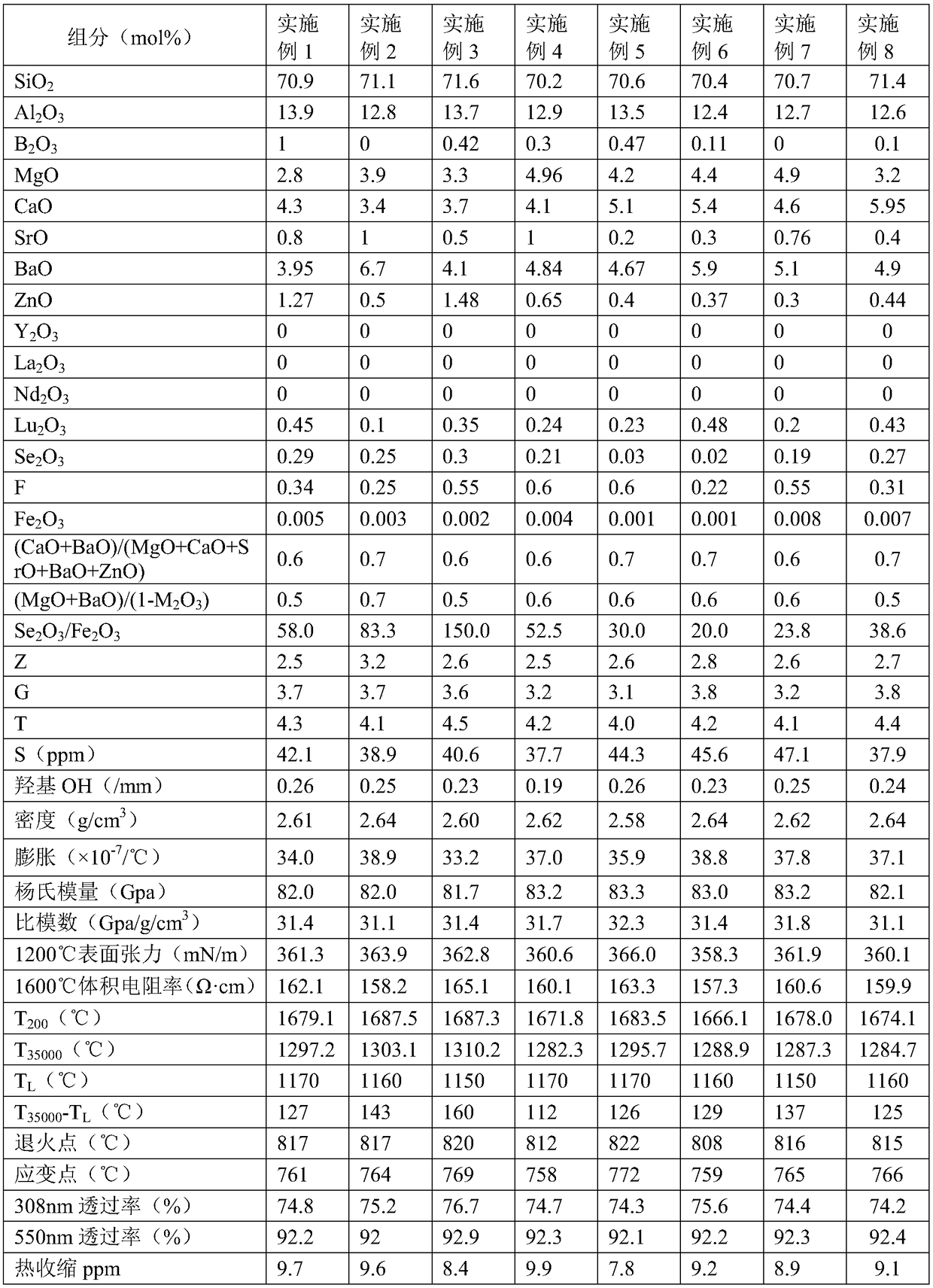

[0104] Weigh the components as shown in Table 1, mix well, and pour the mixture into a high zirconium brick crucible (ZrO 2 >85wt%), then heated in a resistance furnace at 1630°C for 24 hours, and stirred slowly and uniformly with a platinum-rhodium alloy (80wt%Pt+20wt%Rh) stirrer. The molten glass is poured into a stainless steel mold to form a specified block glass product, and then the glass product is annealed in an annealing furnace for 2 hours, and the power is turned off and the furnace is cooled to 25°C. The glass product is cut, ground and polished, then cleaned with deionized water and dried to obtain a glass product with a thickness of 0.5 mm. Various properties of each glass finished product were measured, and the results are shown in Table 1.

Embodiment 9-15

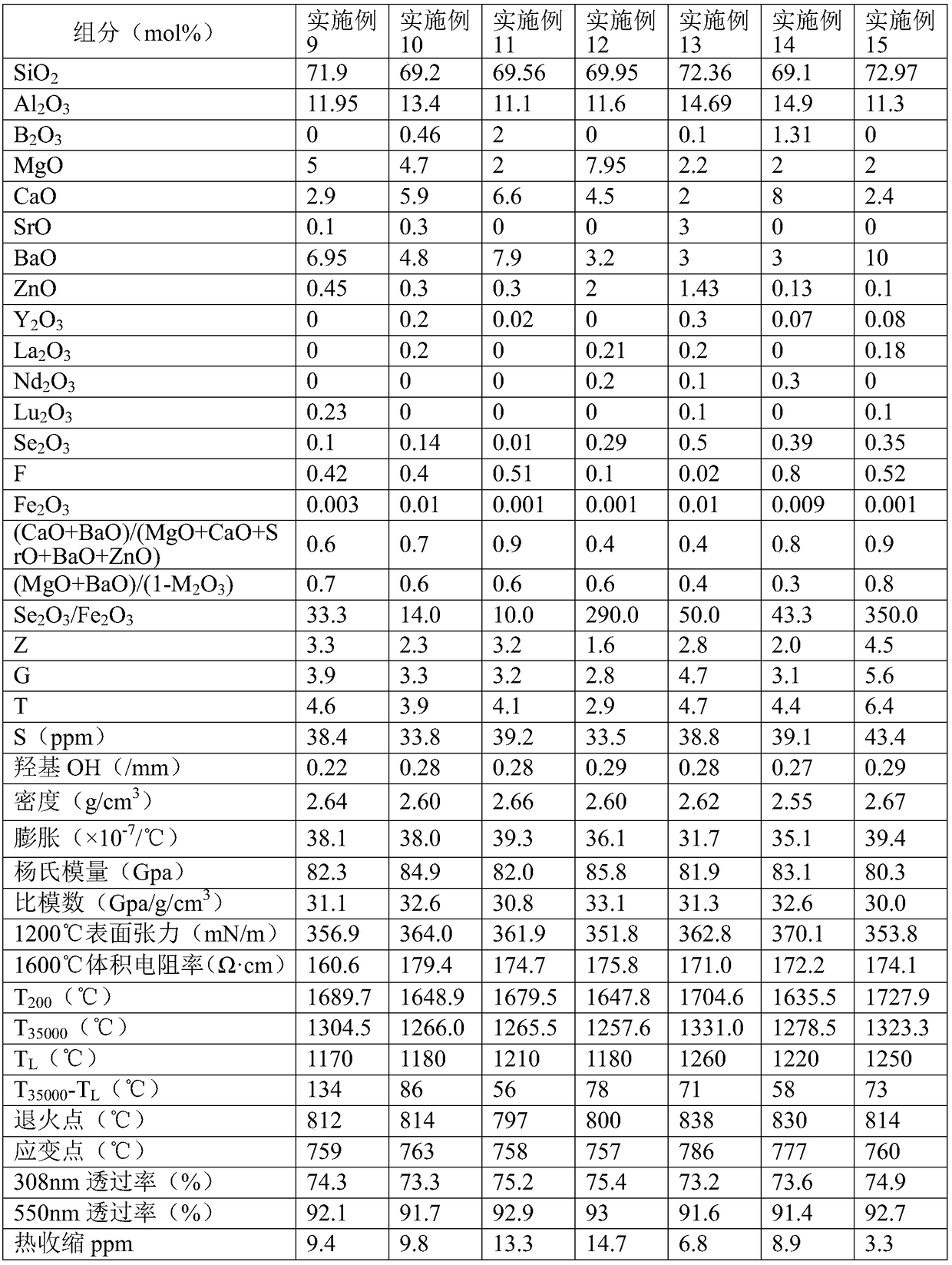

[0106] According to the method of Example 1, the difference is that the composition of the mixture (corresponding to the glass composition) and the performance measurement results of the obtained product are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com