Glass reinforced plastic open caisson modularization pump station capable of being quickly constructed and construction method thereof

A glass fiber reinforced plastic, modular technology, applied in caisson, infrastructure engineering, waterway system and other directions, can solve the problems of only excavation construction, limited application conditions, long construction period, etc., saving construction period and cost, wide application, construction quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

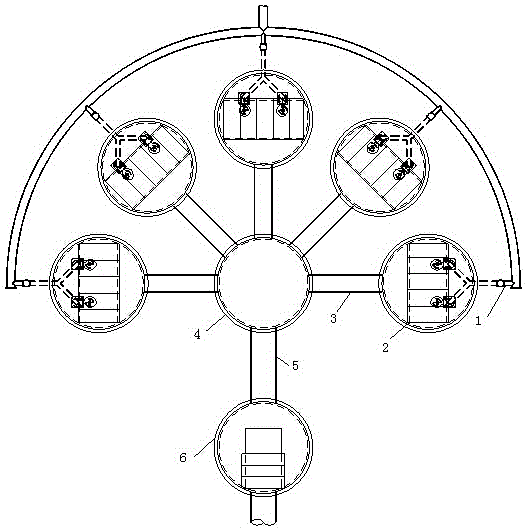

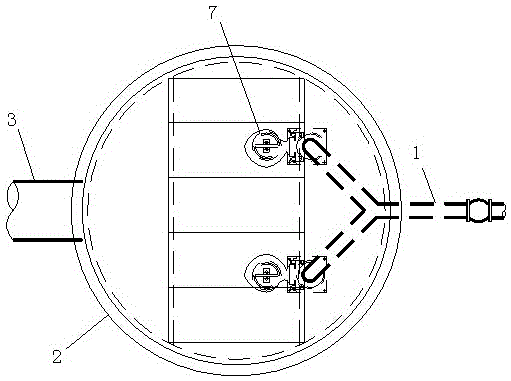

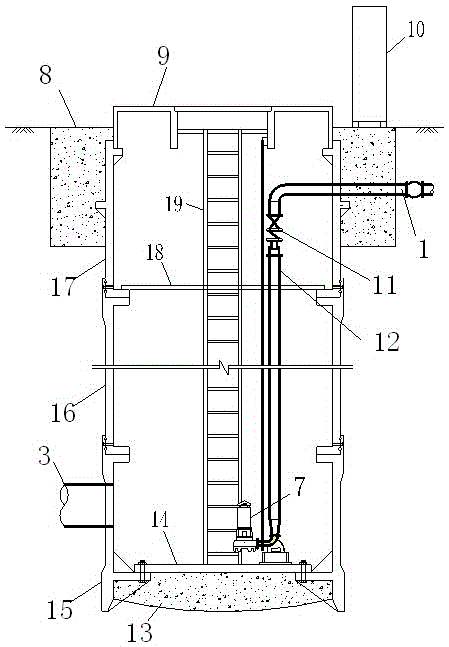

[0014] As shown in the figure, a kind of rapid construction FRP caisson modular pumping station according to the present invention includes a FRP pump room well 2, and the FRP pump room well 2 is connected to a FRP water distribution well 4 through a water distribution pipe 3 Connected, the FRP pump room well 2 communicates with the FRP grid well 6 through the water inlet pipe 5; the FRP pump room well 2 includes a well body, a FRP bottom plate 14 and a FRP well cover 9, and the well body is made of a FRP shaft 15, the fiberglass shaft 16 and the fiberglass shaft 17 are spliced up and down. The bottom of the well body is provided with a fiberglass base plate 14, and the top of the well body is covered with a fiberglass well cover 9. A drainage pump 7 is arranged at the bottom of the well body, and the drainage pump 7 is connected to the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com