Method and die for manufacturing glass fiber reinforced plastic gratings based on vacuum technology, and grating

A vacuum process, glass fiber reinforced plastic technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, wind turbine components, etc., can solve the problems of poor insulation, increased specificity of stainless steel, heavy metal mesh, etc., to improve anti-corrosion performance, processing Low cost and weight saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

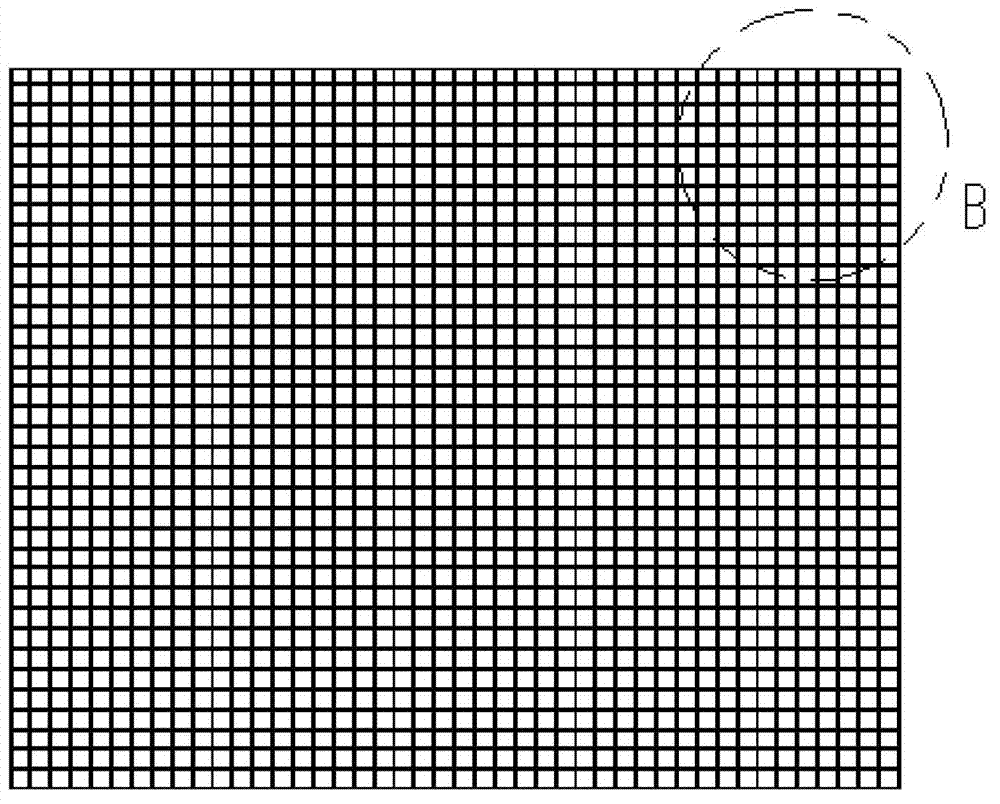

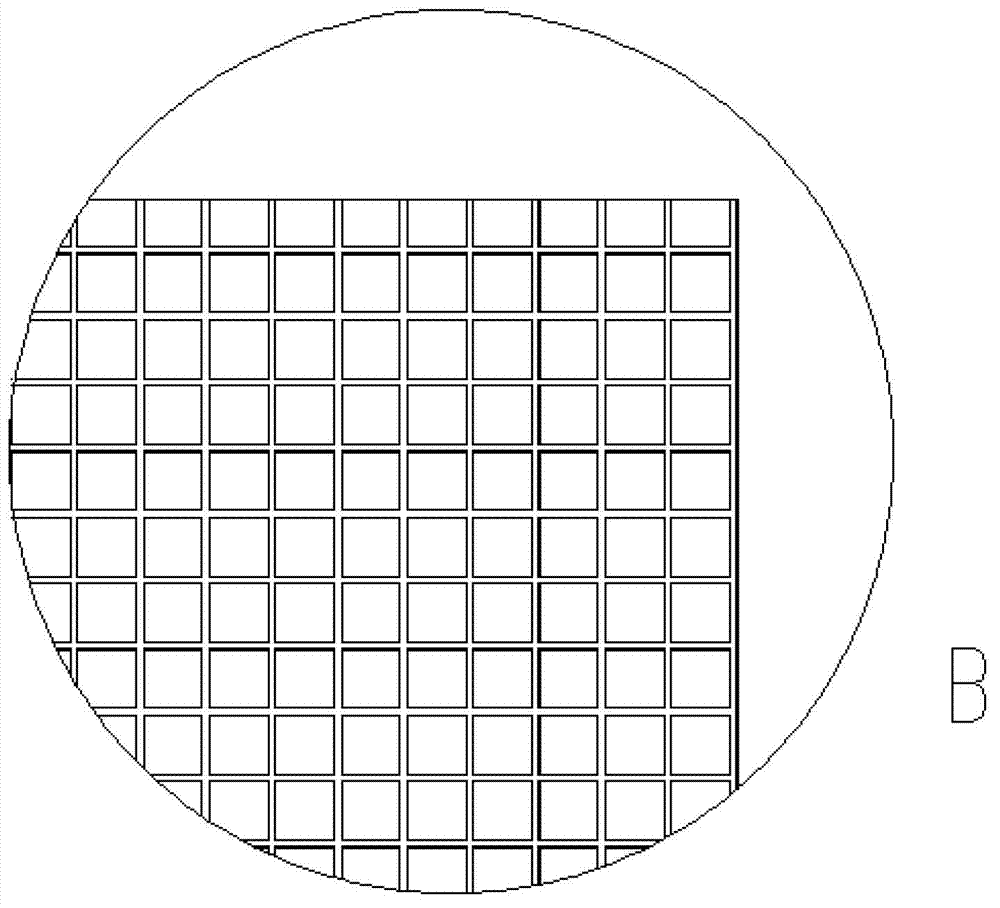

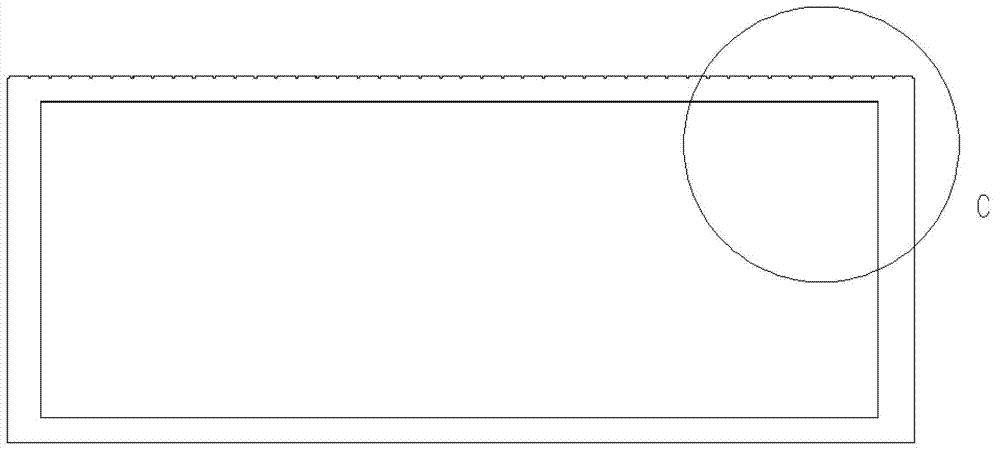

[0040] Such as Figure 1 to Figure 7 In combination with the shown, the technical scheme adopted by the grid mold made of glass fiber reinforced plastic based on vacuum technology according to the present invention comprises a female mold 2, a male mold 1, and a vacuum pump unit; the female mold 1 is connected to the male mold 1 through a sealing strip; 2 and the joint of the male mold 1 are provided with a supporting device 3, an air extraction interface, and a supply interface. The air extraction interface is connected to the vacuum pump unit through the air extraction pipeline 7, and the supply interface is connected to the resin container device through the supply pipeline; the female mold 2 is fixedly connected with the supporting device 3 of the female mold.

[0041] Further, the female mold 2 and the male mold 1 are formed by bonding a mold gel coat layer, a mold resin layer, and a glass fiber layer, and the mold resin layer and the glass fiber layer are not lower than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com