Fluorescent glass fibre reinforced plastic grille and manufacturing method thereof

A technology of FRP and grid, which is applied in the field of FRP grid with fluorescent effect, can solve the problems that FRP grid does not have fluorescent effect, etc., and achieve the effect of improving light transmission performance, good light storage and luminous performance, and good power saving function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

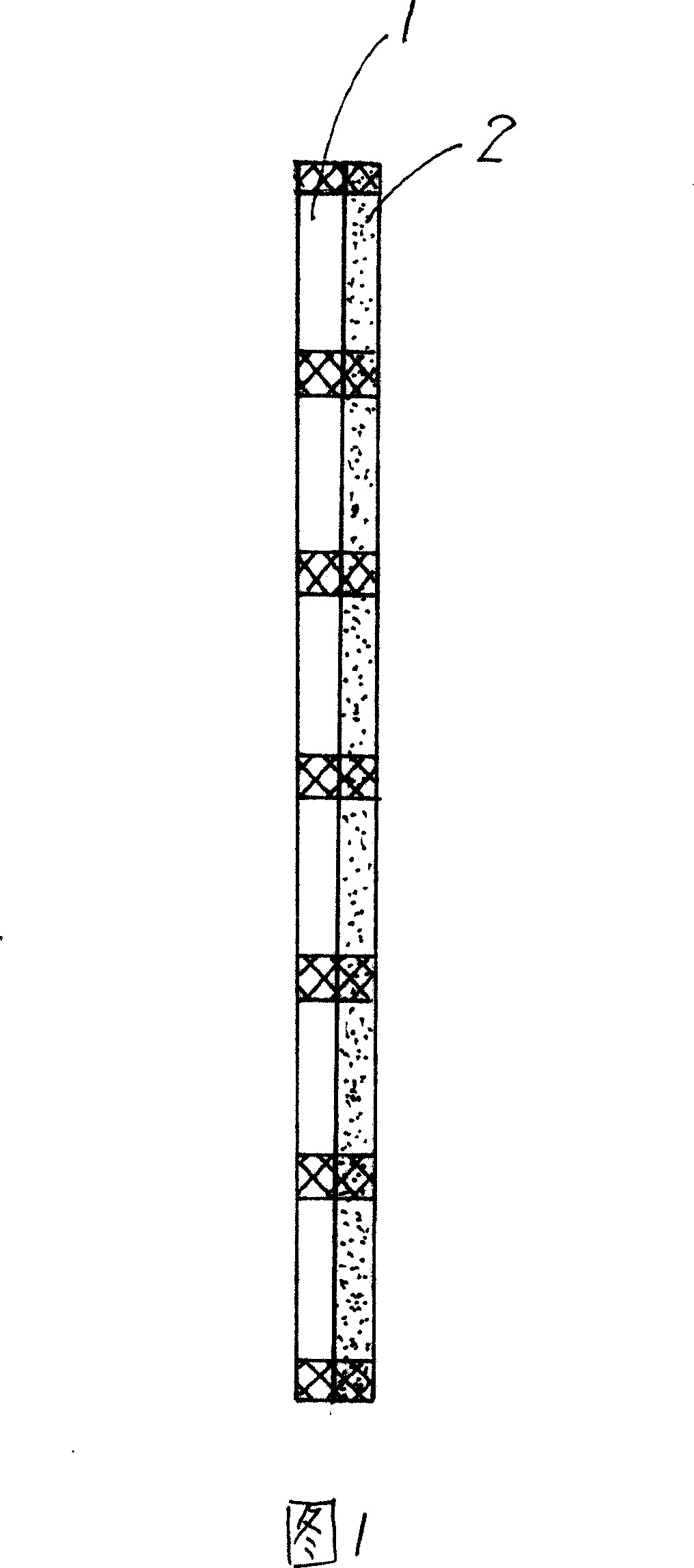

[0034] With reference to accompanying drawing 1, fluorescent FRP grating of the present invention, comprises the grid body 1 that takes resin as base material, glass fiber yarn as reinforcing material, and the phosphor 2 that solidifies with it; Described phosphor 2 can be lattice The layers in the structure of the grid body 1 can also be the entire structure of the grid body 1, and the thickness of the phosphor 2 in this embodiment is 1 / 2 the thickness of the grid body. The resin glue can be one of three kinds of resins: ortho-phenylene resin, m-benzene resin and vinyl resin, and the resin glue in this embodiment is ortho-phenylene resin. The phosphor 2 can be a cured product in which fluorescent powder, accelerator and curing agent are added to the resin glue, or a cured product in which phosphor powder, accelerator and curing agent are added to the resin glue and glass fiber yarn is used as a reinforcing material In this embodiment, fluorescent powder is added to the resin ...

Embodiment 2

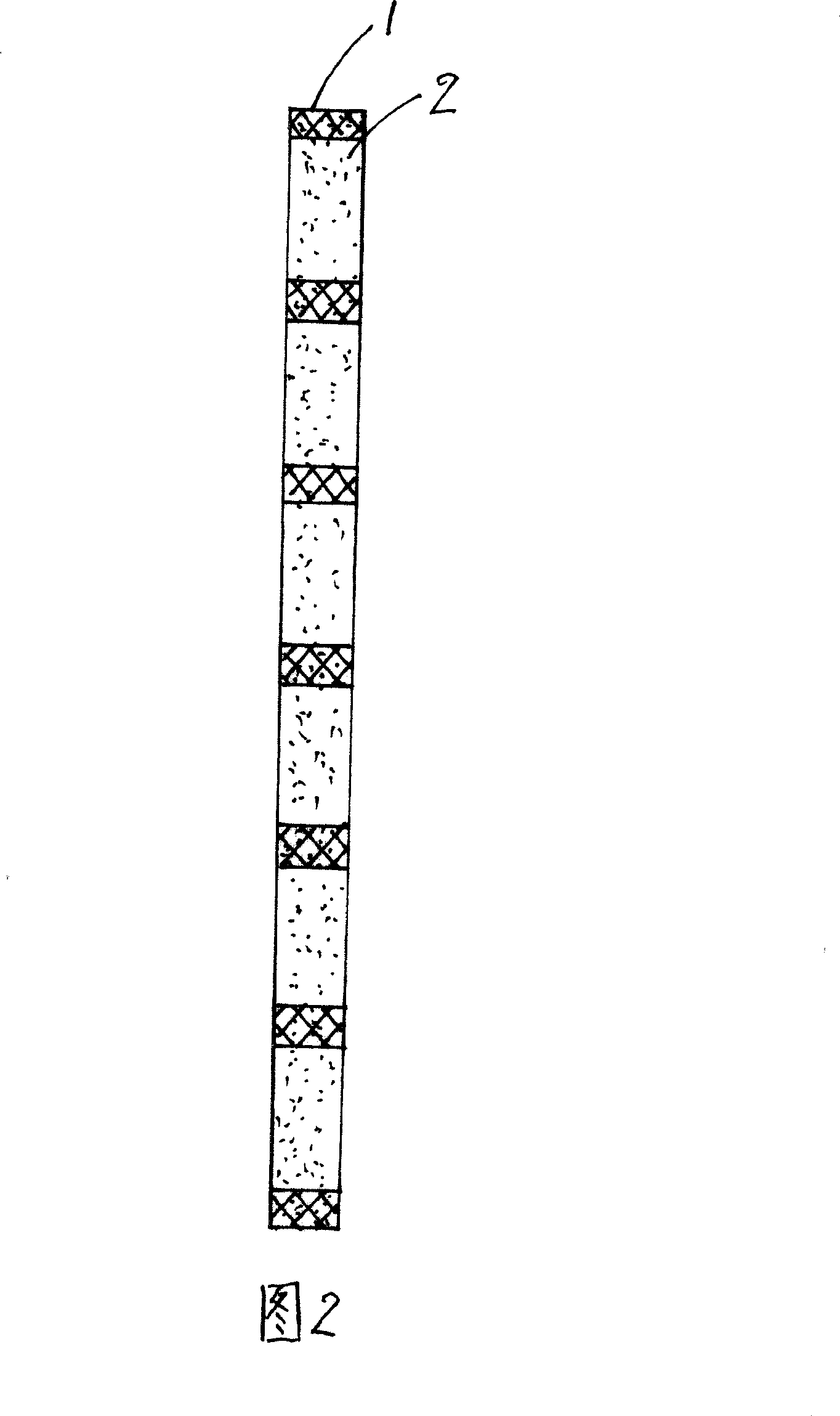

[0048] With reference to accompanying drawing 2, fluorescent FRP grating of the present invention comprises resin as base material, glass fiber yarn as reinforcing material, and fluorescent powder, accelerator, curing agent are added into resin glue and solidified into fluorescent body 2, and the fluorescent body of this embodiment The thickness of 2 is the total thickness of the grid body. The resin glue in this embodiment is o-phthalic resin, the fluorescent powder added in this embodiment is a light-storing luminescent powder with a weight of 20% of the resin, and the accelerator added in this embodiment is cobalt naphthenate with a weight of 0.07% of the resin. The solidifying agent is the methyl ethyl ketone peroxide of resin weight 1.6%, and the present embodiment selects the non-alkali glass fiber yarn as reinforcing material.

[0049] A method for producing the above-mentioned fluorescent FRP grating, comprising the following steps:

[0050] ① Preheat the special mold...

Embodiment 3

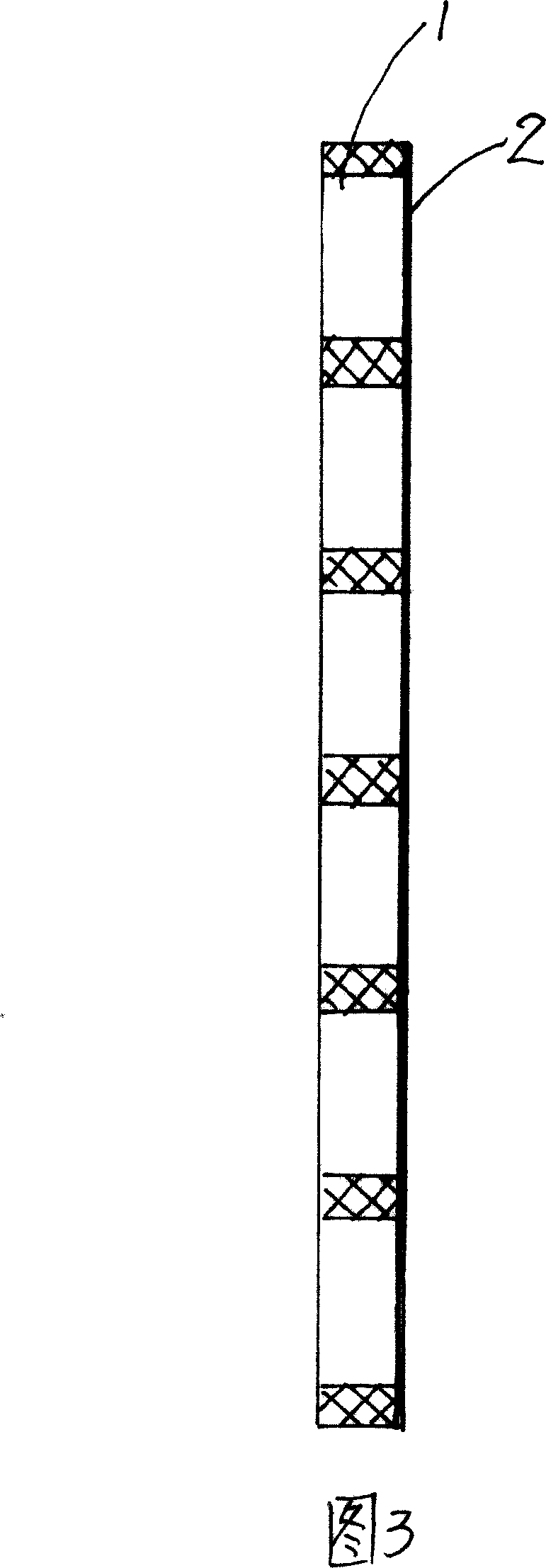

[0061]With reference to accompanying drawing 3, fluorescent FRP grating of the present invention, comprises the grid body 1 that takes resin as base material, glass fiber yarn as reinforcing material, and the phosphor 2 that solidifies with it; Described phosphor 2 can be lattice The layer in the structure of the grid body 1 can also be the entire structure of the grid body 1 , and the phosphor 2 in this embodiment is a layer of the grid body 1 . The resin glue in this embodiment is m-benzene resin. Phosphor 2 in this embodiment is a cured product in which phosphor powder, accelerator, and curing agent are added to the resin glue. The phosphor powder added in this embodiment is a light-storing luminescent powder with a resin weight of 30%. The accelerator added in this embodiment is resin 0.08% by weight of cobalt naphthenate, the curing agent added in this embodiment is methyl ethyl ketone peroxide with a resin weight of 1.7%, and medium-alkali glass fiber yarn is selected as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com