Automatic continuous production device for fiber reinforced plastic gratings

A production device and FRP technology, which is applied in the field of FRP grating production equipment, can solve the problems of resin and fiber material waste, low output strength, and difficult engineering needs, etc., so as to improve the utilization rate of resin, improve product quality, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

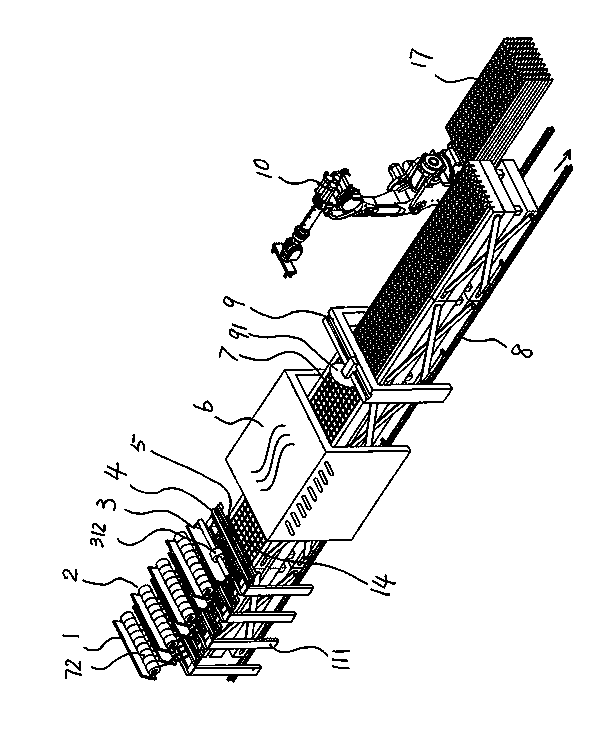

[0033] The structure of the automatic continuous production device for FRP grating and its preparation method provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

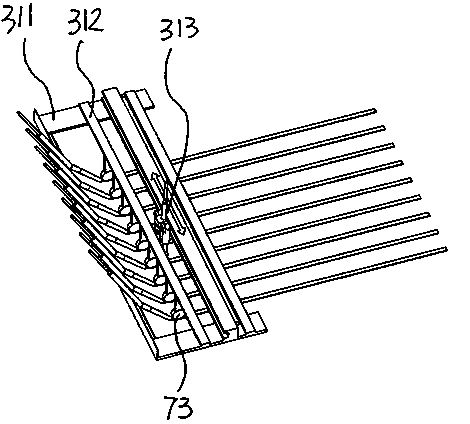

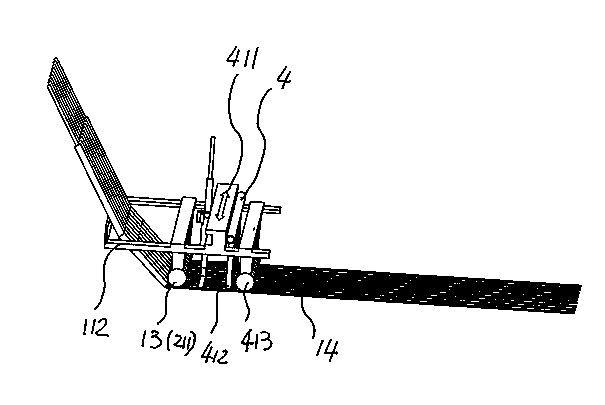

[0034] like figure 1 , 2 Shown is a structural schematic diagram of the automatic continuous production device for FRP gratings provided by the present invention. The structure of the device includes four supporting frames 111 respectively supporting and fixing four longitudinal fiber laying mechanisms 2 and transverse fiber laying mechanisms 3 and four glue injection mechanisms 4 and compaction mechanisms 5 arranged at intervals. mechanism, and the resin curing mechanism 6 arranged in sequence after the laying mechanism, the grid cutting mechanism 9 after the mold is demoulded, and the handling mechanism 10 and the longitudinal groove 711 which is arranged in the above-mentioned support bracket and can be driven by the power mechanism to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com