Fiber reinforced plastic grid with automatic luminescence function, and production process thereof

A technology of automatic luminescence and production process, which is applied in the field of FRP grating and its production process, which can solve the problems of not being able to see the specification and shape clearly, not having automatic luminescence, and easy settlement of luminescent powder, so as to achieve stable and reliable product quality and broaden the scope of use , good effect of automatic lighting function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

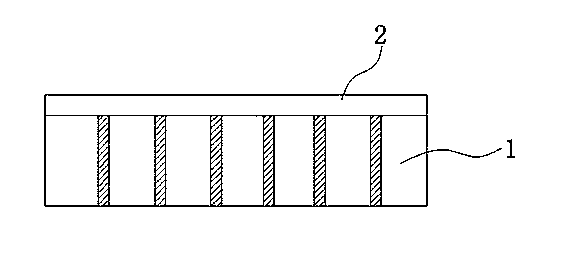

[0031] See attached figure 1 , and its implementation method is described:

[0032] The FRP grating with automatic luminous function of the present invention comprises a grid body 1 with resin as a base material and glass fiber yarn as a reinforcing material. The grid body 1 is a luminous body, and the surface of the grid body 1 is provided with a luminescent layer 2 .

[0033] The luminescent layer 2 is a cured product of resin glue, luminescent powder, fumed silica anti-falling agent, cobalt isooctanoate accelerator and methyl ethyl ketone peroxide curing agent. In this embodiment of the present invention, the amount of luminescent powder added is 1% of the weight of the resin; the amount of fumed silica added is 0.6% of the weight of the resin; the amount of cobalt isooctanoate added is 1% of the weight of the resin; The methyl ethyl ketone peroxide is 1% by weight of the resin.

[0034] In this embodiment of the present invention, the grid body 1 and the light emitting ...

Embodiment 2

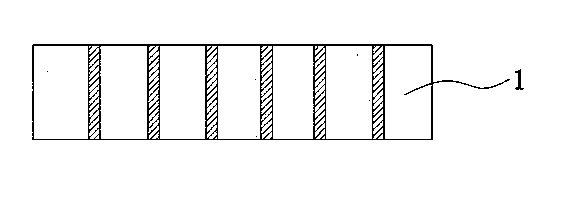

[0048] See attached figure 2 , and its implementation method is described:

[0049] The fiberglass grating with automatic lighting function of the present invention includes a grid body 1 with resin as a base material and glass fiber yarn as a reinforcing material. The grid body 1 is a luminous body, and the grid body 1 emits light as a whole.

[0050] The grid body 1 is a cured product of resin glue, luminescent powder, fumed silica anti-falling agent, cobalt isooctanoate accelerator and methyl ethyl ketone peroxide curing agent. In this embodiment of the present invention, the amount of luminescent powder added is 2.2% of the weight of the resin, the amount of the anti-falling agent is 1.1% of the weight of the resin, the amount of the accelerator is 0.8% of the weight of the resin, and the amount of the curing agent 1% of resin weight.

[0051] In this embodiment of the invention, the grid body 1 is reinforced by glass fiber yarns.

[0052] The production process of FRP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com