Glass fiber reinforced plastic grating hollow plate and production method thereof

A production method and technology of glass steel plate, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of panel transverse shear stress damage, low production efficiency, poor product stability, etc., to slow down convection. The effect of heat conduction, high production efficiency and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

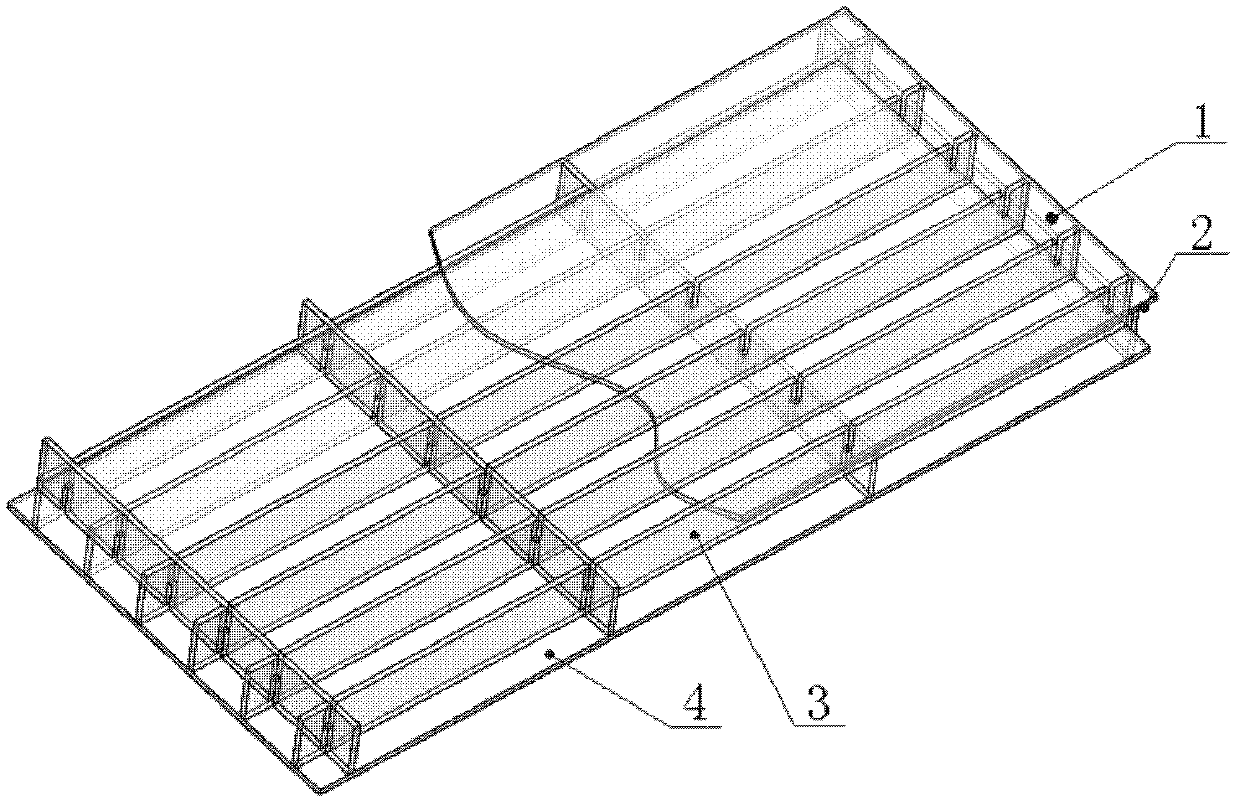

[0051] The FRP grating hollow panel of this embodiment includes an outer panel 2, a grid 3 and an inner panel 4, and the three are bonded from top to bottom to form a whole.

[0052] The outer panel 2 and the inner panel 4 are glass fiber reinforced plastic rectangular flat plates with the same size. The outer panel 2 and inner panel 4 are preferably made of transparent flame-retardant glass steel plates. The outer panel 2 and inner panel 4 have a length of 6-12m, a width of 0.8-2.4m, and a thickness of 1.2-3.5mm. In this embodiment, both the outer panel 2 and the inner panel 4 are made of transparent flame-retardant glass steel plates with a length of 6m, a width of 1m, and a thickness of 2mm.

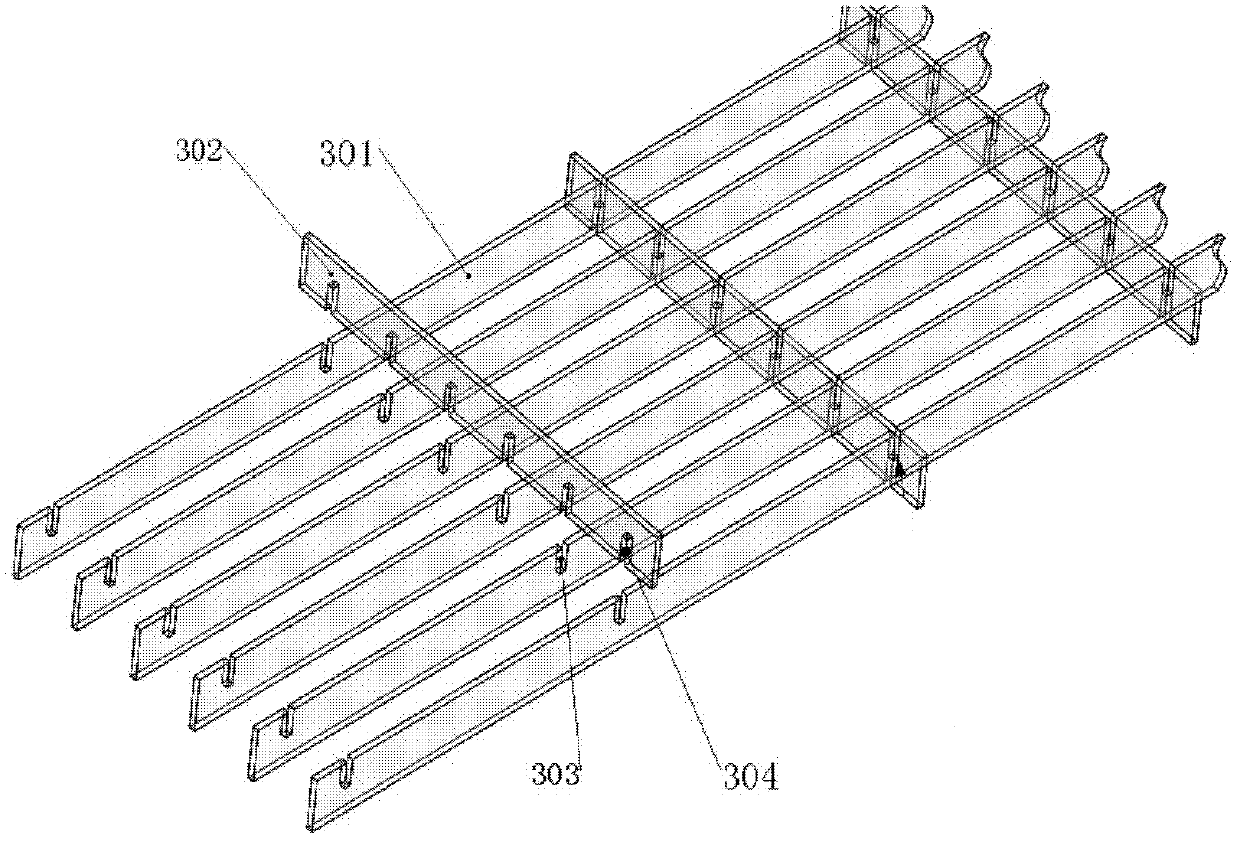

[0053] The grid 3 includes several longitudinal ribs 301 and several transverse partitions 302, and the longitudinal ribs 301 and the transverse partitions 302 are rectangular flat plates made of glass fiber reinforced plastic: the length of each longitudinal rib 301 is the same as th...

Embodiment 2

[0057] The difference between the FRP grating hollow panel of this embodiment and the first embodiment is that the exposed surface of the outer panel 2 , that is, the upper surface of the outer panel 2 is covered with an anti-aging film 1 . The anti-aging film 1 is preferably a polyester film with a thickness of 15 μm treated with a corona surface.

Embodiment 3

[0059] The production method of the FRP grid hollow plate described in embodiment 2 specifically comprises the following steps:

[0060] Step (a) Prepare grid 3

[0061] Step (a1) Prepare grid 3 glass steel plate

[0062] Lay a polyester film on the production platform as a carrying process film, and move forward synchronously with the equipment. The thickness of the polyester film is preferably 20 μm; evenly coat the resin glue on the polyester film; then spread the alkali-free Glass fiber felt, the specification of described alkali-free glass fiber felt is preferably 450g / m 2 ; After the alkali-free glass fiber mat is soaked, cover another layer of carrying process film to form a sandwich belt; then gradually run to the oven for heating and curing molding, in this embodiment, the heating temperature is 40 ~ 80 ° C, run The speed is 1.5m / min, and the curing time is 15-20 minutes; remove the polyester film on both surfaces after curing and molding.

[0063] Described resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com