Moulded glass fibre reinforced plastic grille and manufacturing method thereof

A glass fiber reinforced plastic and grid technology, applied in building components, buildings, building structures, etc., can solve the problem that glass fiber reinforced plastic grid can only be used as a platform, floor, trench cover, etc., to achieve high strength, easy to trim corners, Reliable quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

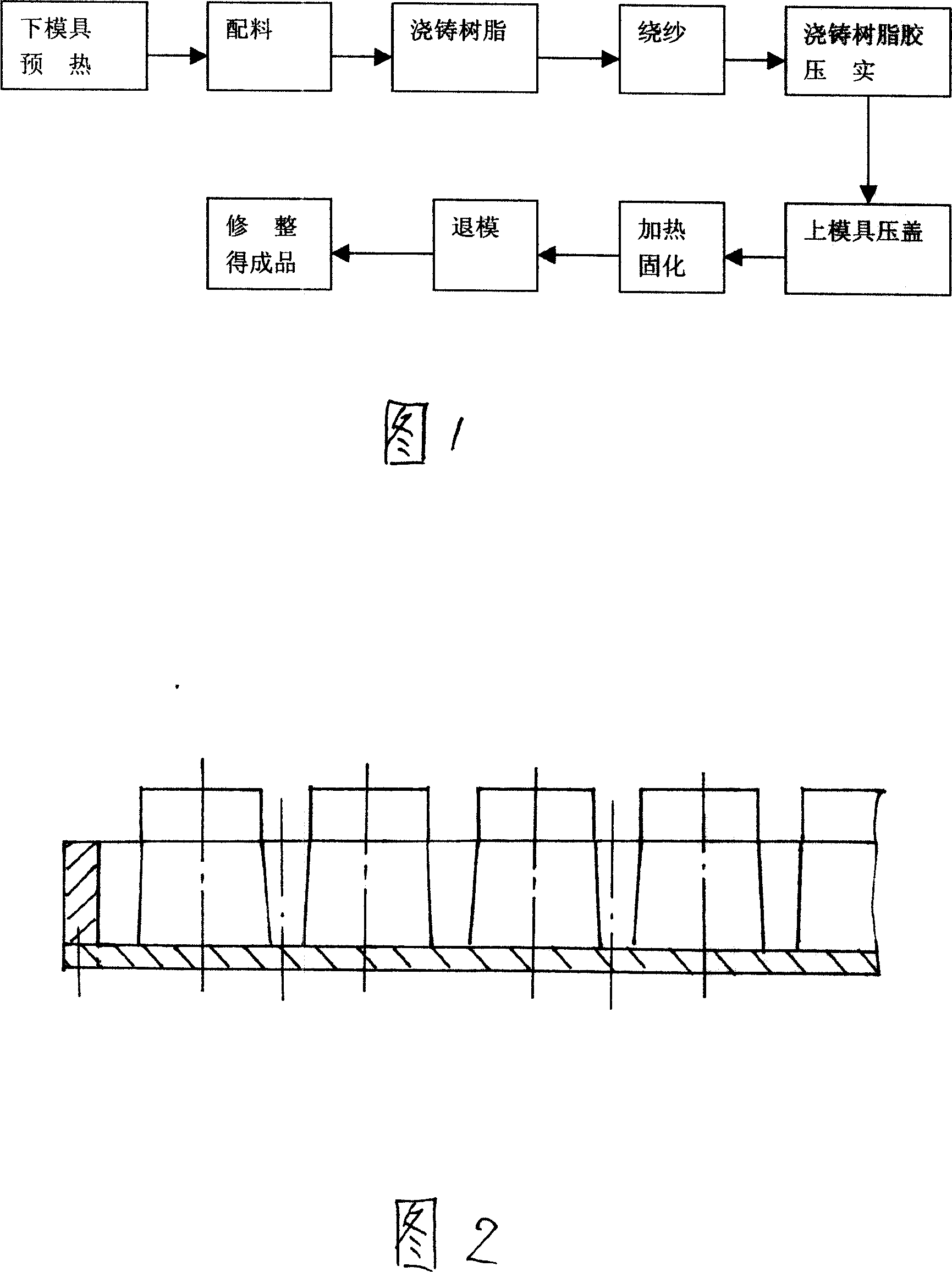

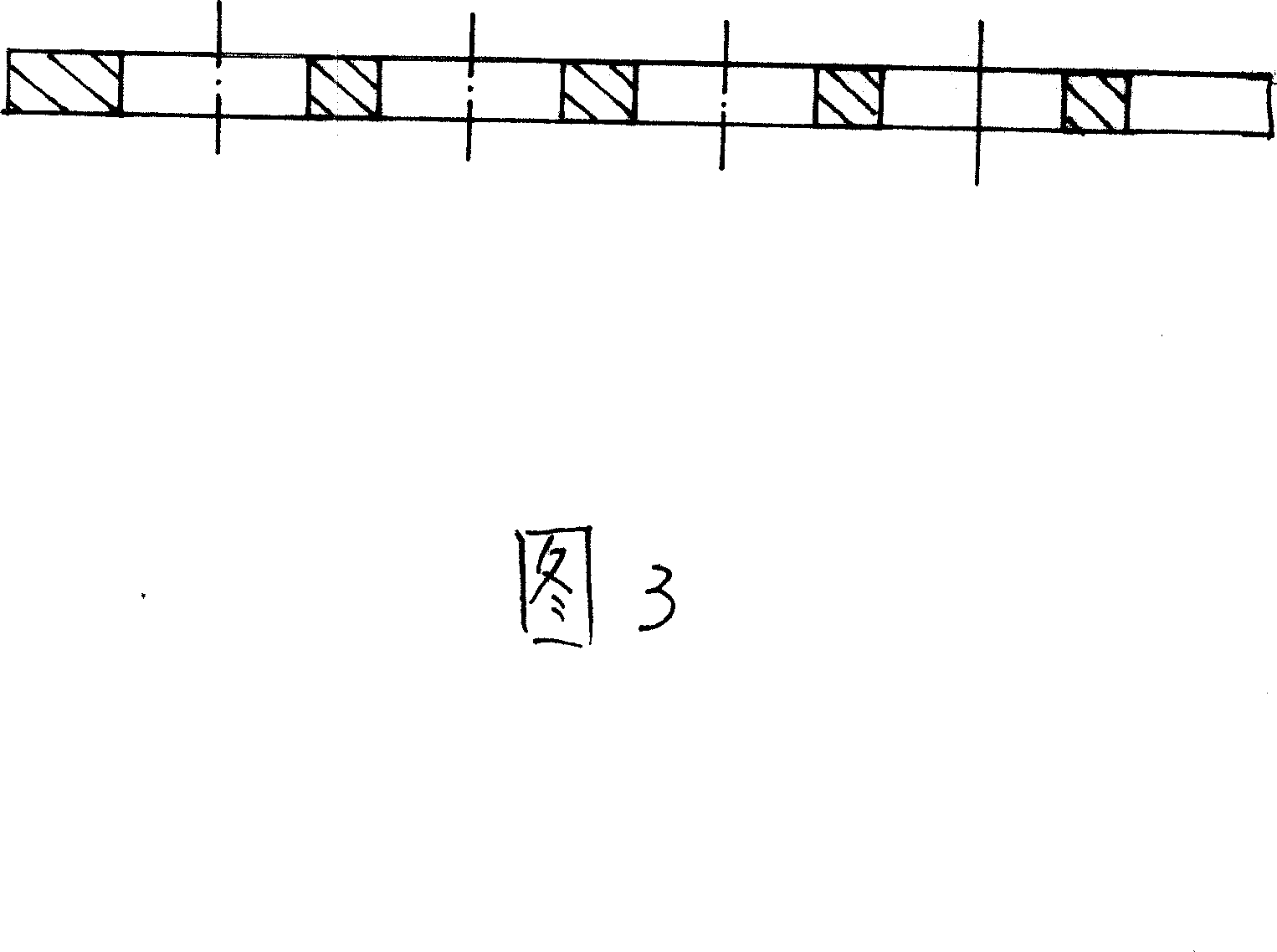

[0029] With reference to accompanying drawing 1, accompanying drawing 2, accompanying drawing 3, molded fiberglass grating of the present invention, take resin as base material, add appropriate accelerator, curing agent, take glass fiber yarn as reinforcing material and form through molding; The above-mentioned resin is one of ortho-phenylene resin, m-phenylene resin and vinyl resin. The appropriate amount of accelerator added means that the added weight group is: 0.5-3% cobalt isozincate with resin weight. In this embodiment, 2% cobalt isozincate with resin weight is added as accelerator. The appropriate amount of curing agent added means that the added weight group is: methyl ethyl ketone peroxide with a resin weight of 0.5-3%. In this embodiment, methyl ethyl ketone peroxide with a resin weight of 2% is added as a curing agent.

[0030] A method for producing the above-mentioned molded FRP grating, comprising the following steps:

[0031] ① Preheat the special lower mold a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com