Retractable ditch trestle bridge

A telescopic and channel technology, applied in the directions of portable bridges, bridges, bridge parts, etc., can solve the problems that can not meet the needs of construction personnel and management personnel patrol inspection, the method of erecting the trestle is not uniform, and the maintenance cost is high. Light, good comprehensive economic benefits, low installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

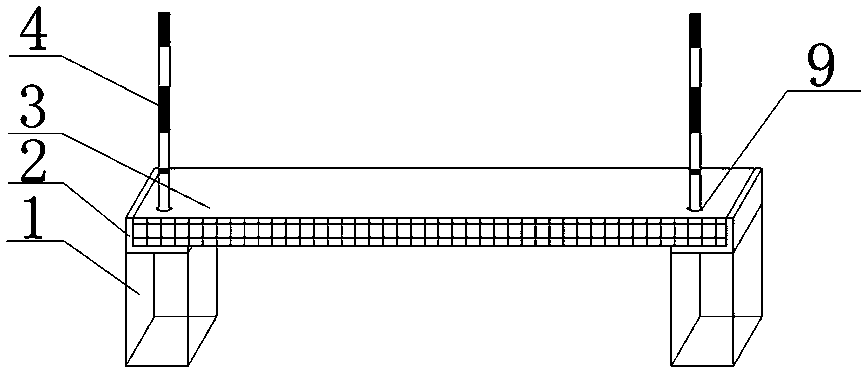

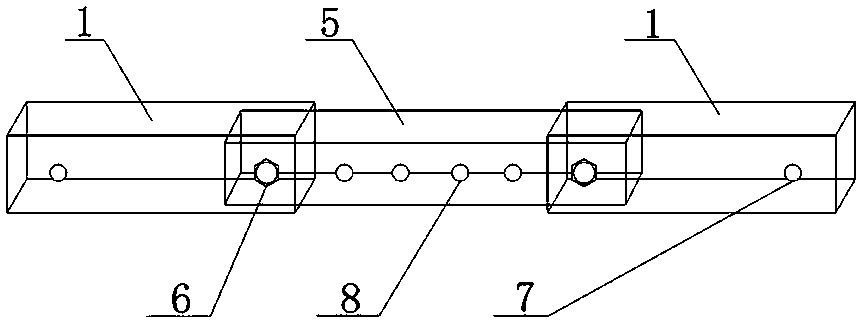

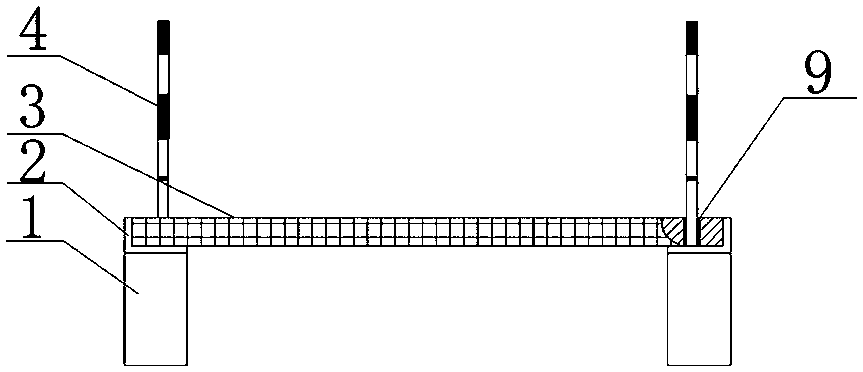

[0013] Example 1, such as Figure 1-Figure 2 As shown, the present invention provides a retractable channel trestle bridge, its structure is: there are two steel girders (1), the two ends of the steel girders (1) are provided with through holes A (7), and the two steel girders (1) They are connected by a sleeve (5), and the sleeve (5) is provided with a through hole B (8), and the limit bolt (6) connects the steel beam (1) through the through hole A (7) and the through hole B (8). ) is fixed with the sleeve (5), the length of the steel beam (1) can be adjusted through the sleeve (5) and the limit bolt (6), the limit angle steel (2) is fixed on the steel beam (1), and the steel beam (1) The bridge deck (3) is fixed with the limit angle steel (2), and sockets (9) are respectively provided on both sides of the bridge deck (3), and vertical railings (4) are inserted in the sockets (9), and the vertical railings (4) are fixed There are railings (10).

[0014] The bridge deck (3) ...

Embodiment 2

[0018] Example 2, such as Figure 1-Figure 2 As shown, the present invention provides a retractable channel trestle bridge, its structure is: there are two steel girders (1), the two ends of the steel girders (1) are provided with through holes A (7), and the two steel girders (1) They are connected by a sleeve (5), and the sleeve (5) is provided with a through hole B (8), and the limit bolt (6) connects the steel beam (1) through the through hole A (7) and the through hole B (8). ) is fixed with the sleeve (5), the length of the steel beam (1) can be adjusted through the sleeve (5) and the limit bolt (6), the limit angle steel (2) is fixed on the steel beam (1), and the steel beam (1) The bridge deck (3) is fixed with the limit angle steel (2), and sockets (9) are respectively provided on both sides of the bridge deck (3), and vertical railings (4) are inserted in the sockets (9), and the vertical railings (4) are fixed There are railings (10).

[0019] The bridge deck (3) ...

Embodiment 3

[0023] Example 3, such as Figure 1-Figure 2 As shown, the present invention provides a retractable channel trestle bridge, its structure is: there are two steel girders (1), the two ends of the steel girders (1) are provided with through holes A (7), and the two steel girders (1) They are connected by a sleeve (5), and the sleeve (5) is provided with a through hole B (8), and the limit bolt (6) connects the steel beam (1) through the through hole A (7) and the through hole B (8). ) is fixed with the sleeve (5), the length of the steel beam (1) can be adjusted through the sleeve (5) and the limit bolt (6), the limit angle steel (2) is fixed on the steel beam (1), and the steel beam (1) The bridge deck (3) is fixed with the limit angle steel (2), and sockets (9) are respectively provided on both sides of the bridge deck (3), and vertical railings (4) are inserted in the sockets (9), and the vertical railings (4) are fixed There are railings (10).

[0024] The bridge deck (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com