Load testing machine

A load test and carrier technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of no testing device and failure to detect FRP grids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

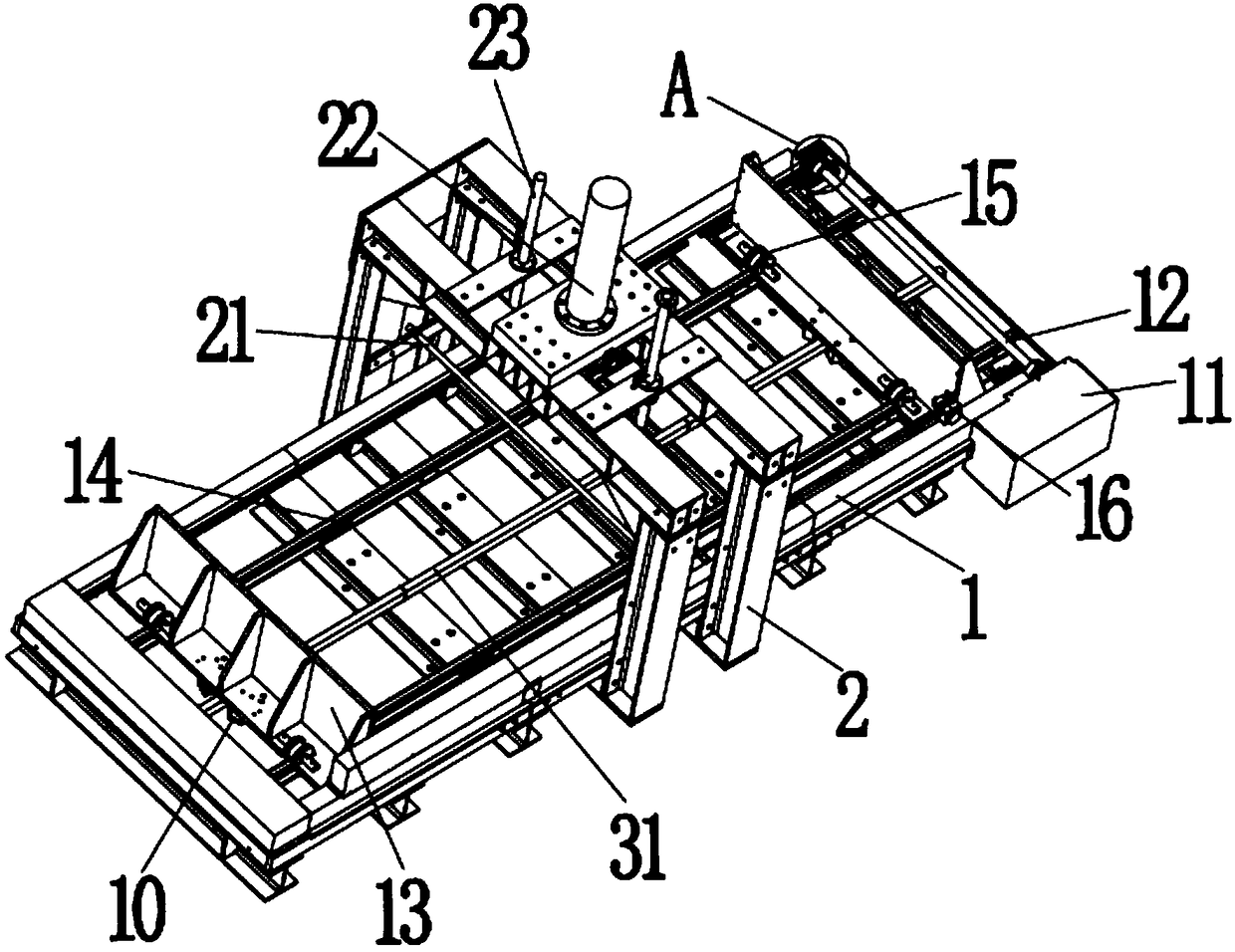

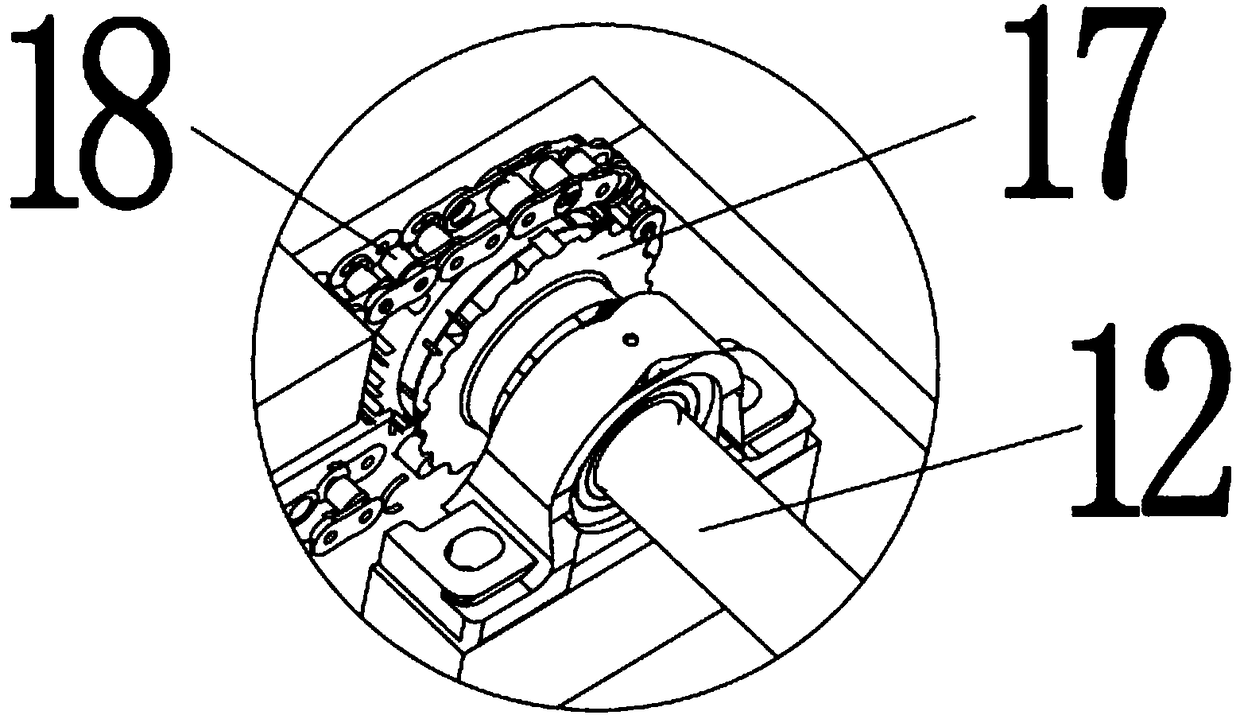

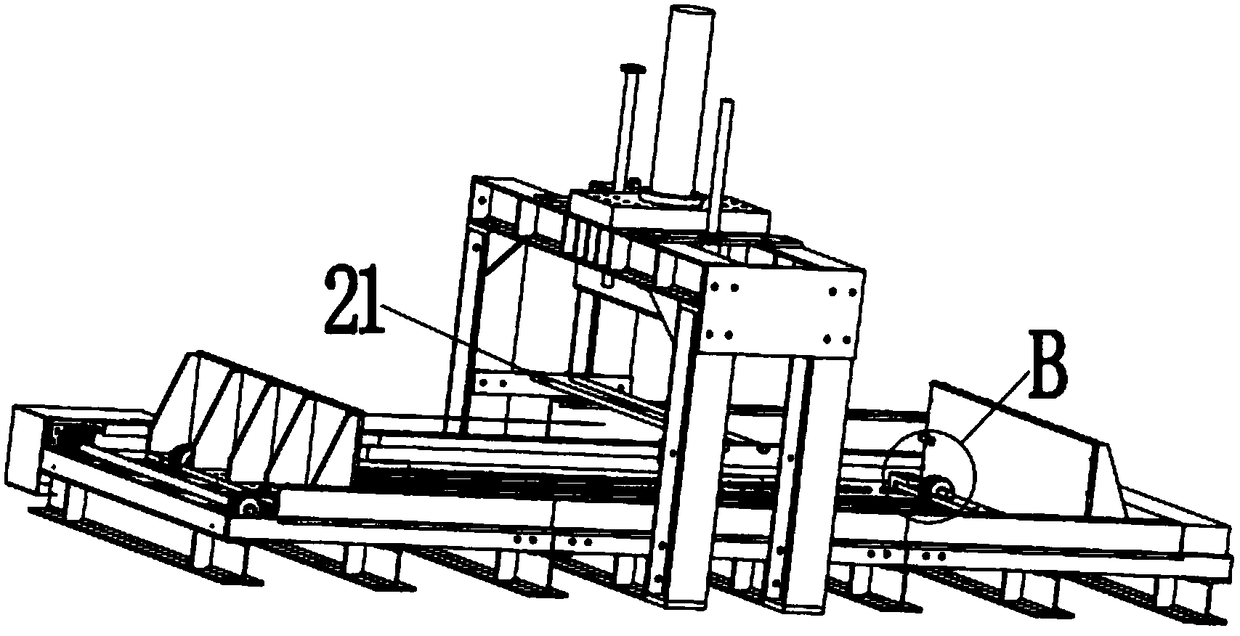

[0022] Such as Figure 1-5 As shown, a load testing machine according to the present invention is characterized in that: it comprises a carrier 1 and a test frame 2, and the test frame 2 cooperates with the carrier 1; the carrier 1 is provided with a moving assembly and Mobile support 13; the mobile support 13 is set to two, respectively located at the two ends of the carrier 1; the mobile assembly controls two mobile support 13 to move towards each other at the same time; the mobile assembly includes a guide rail 14, an electrical control box 11 , rotating shaft 12 and transmission chain 18; Described guide rail 14 is provided with two, increases stability; The two ends of described rotating shaft 12 are respectively provided with the transmission gear 17 that cooperates with transmission chain 18; Described electrical control box 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com