Full-automatic compressed tea dissolving recovering machine

A recycling machine and tea compaction technology, which is applied in tea processing before extraction, etc., can solve the problems of unreachable, increased labor costs, and low quality of manual kneading, achieve good decomposition efficiency and degree, and ensure food hygiene and safety. The effect of improving the economic efficiency of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention adopts the mechanical structure in which the fixed twist teeth and the rotating twist teeth are interlaced with each other to mechanize the dissolution and recovery of the unqualified products that are not up to standard due to physical properties such as shape and weight produced during the production, transportation, storage and other process links of pressed Pu-erh tea. technology.

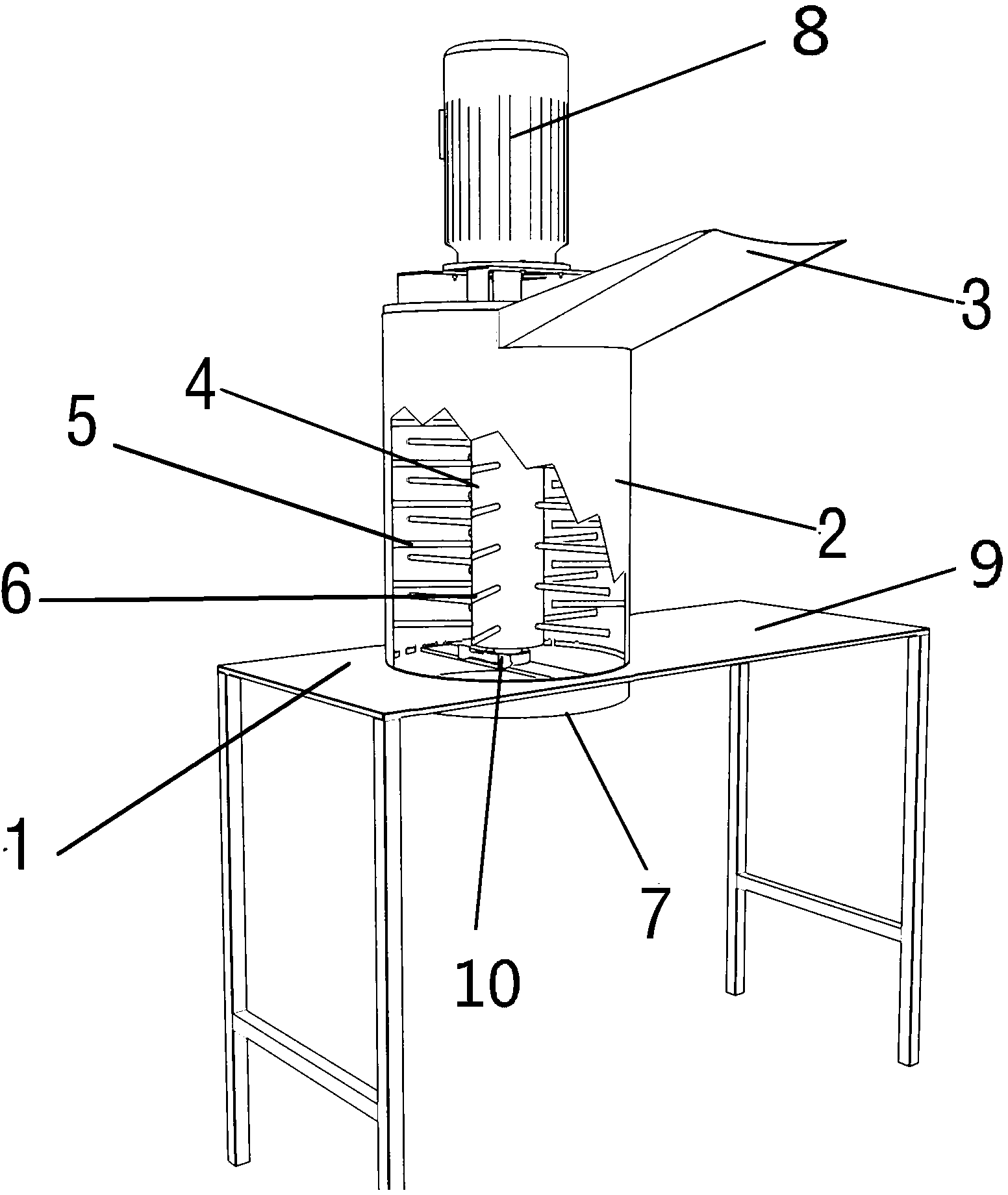

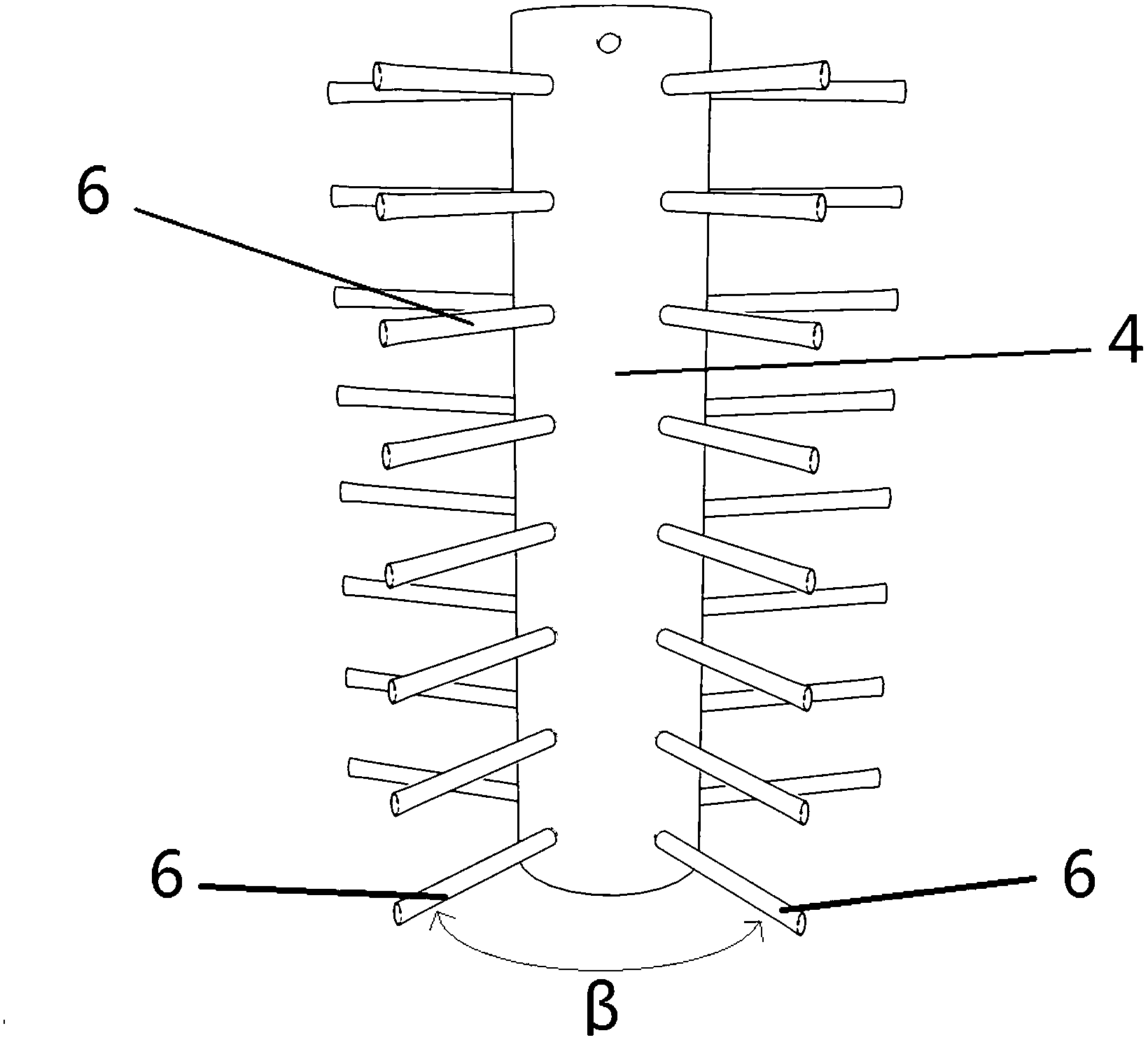

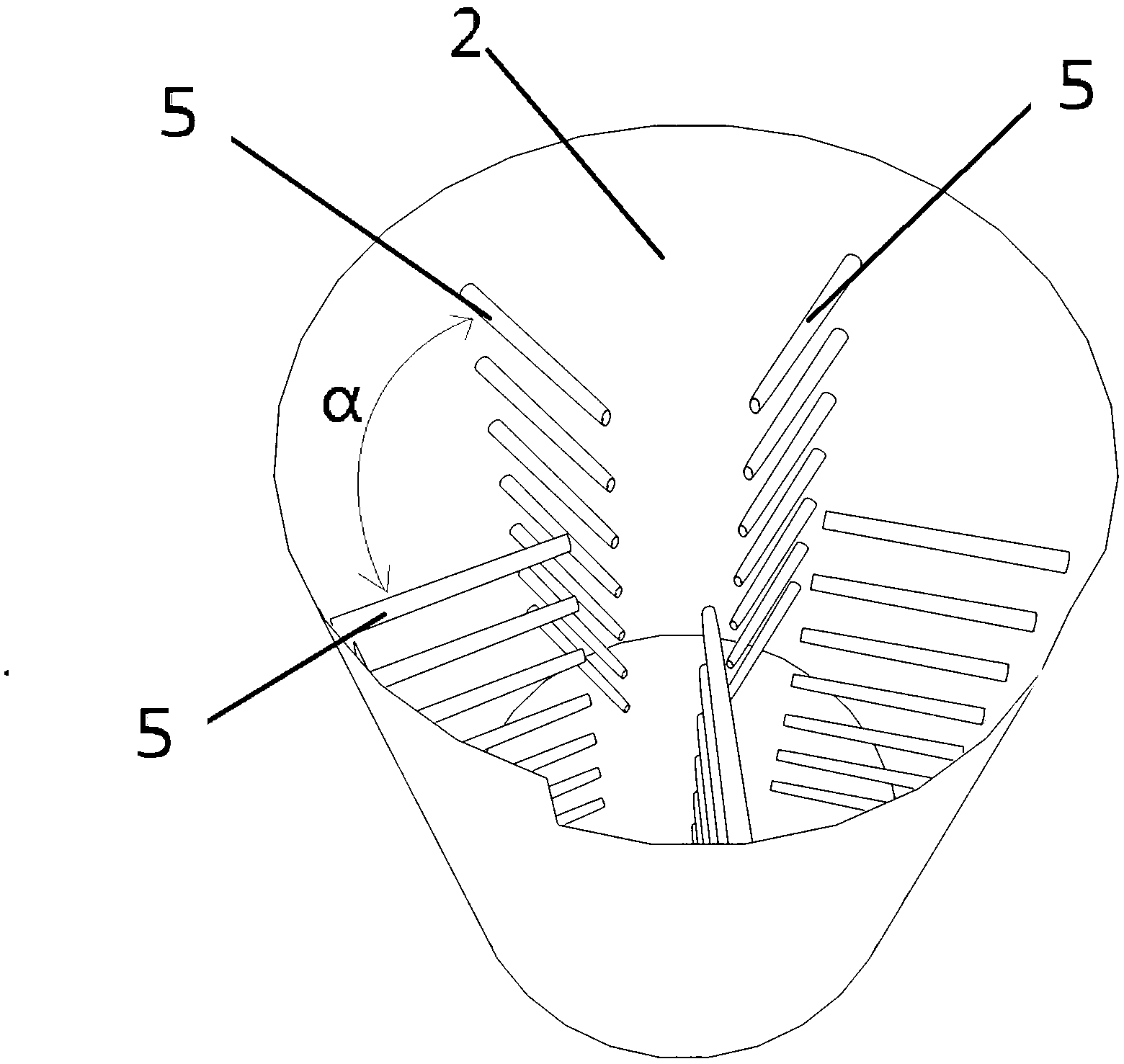

[0024] Such as figure 1 As shown, it consists of a frame 1, a drum box body 2, a feeding port 3, a central rotating shaft 4, a fixed twisted tooth 5, a rotating twisted tooth 6, a feeding port 7, a motor 8, a waiting platform 9 and a bearing seat 10 To form a fully automatic compressed tea dissolving and recycling machine, the drum box 2 is placed at the center of the frame 1, the feeding port 3 is placed at the top of the drum box 2, and the feeding port 7 is placed at the bottom of the drum box 2 At the bottom, the motor 8 is placed directly above the drum box 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com