Electrostatically-spun nanofiber-based double-skin-layer forward osmosis membrane and preparation method thereof

An electrospinning and nanofiber technology, applied in the field of electrospinning nanofiber-based double-skinned forward osmosis membrane and its preparation, can solve problems such as imperfection, hinder industrial development, etc. chemical phenomenon, the effect of excellent anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

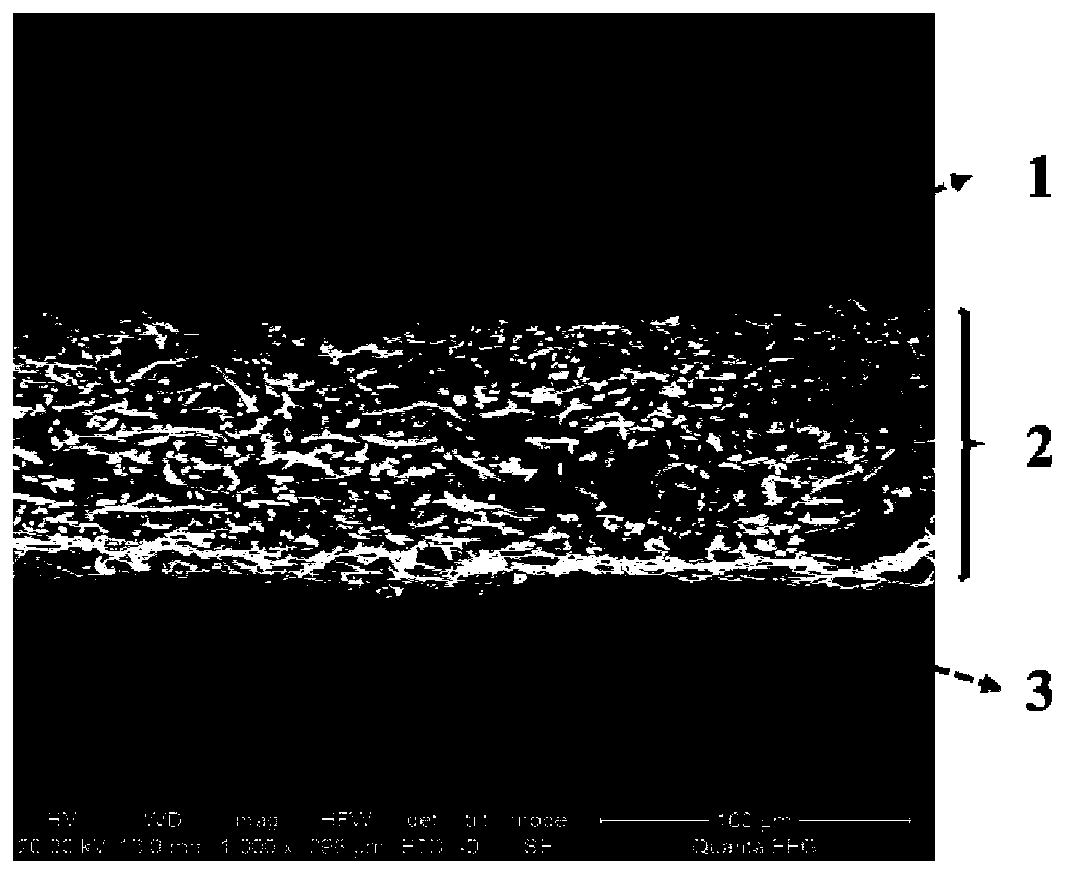

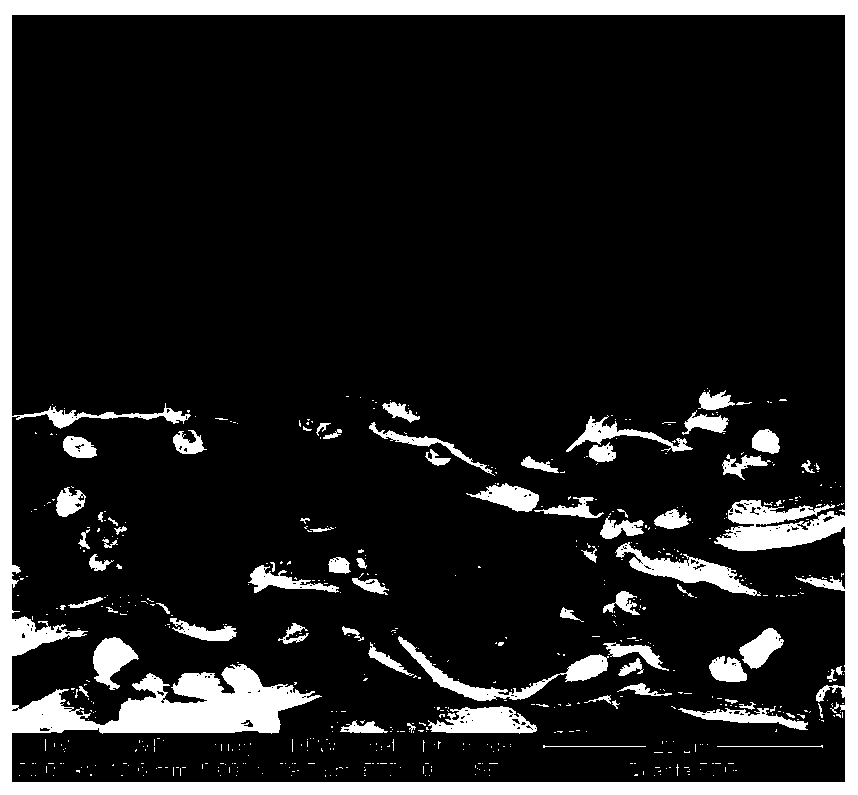

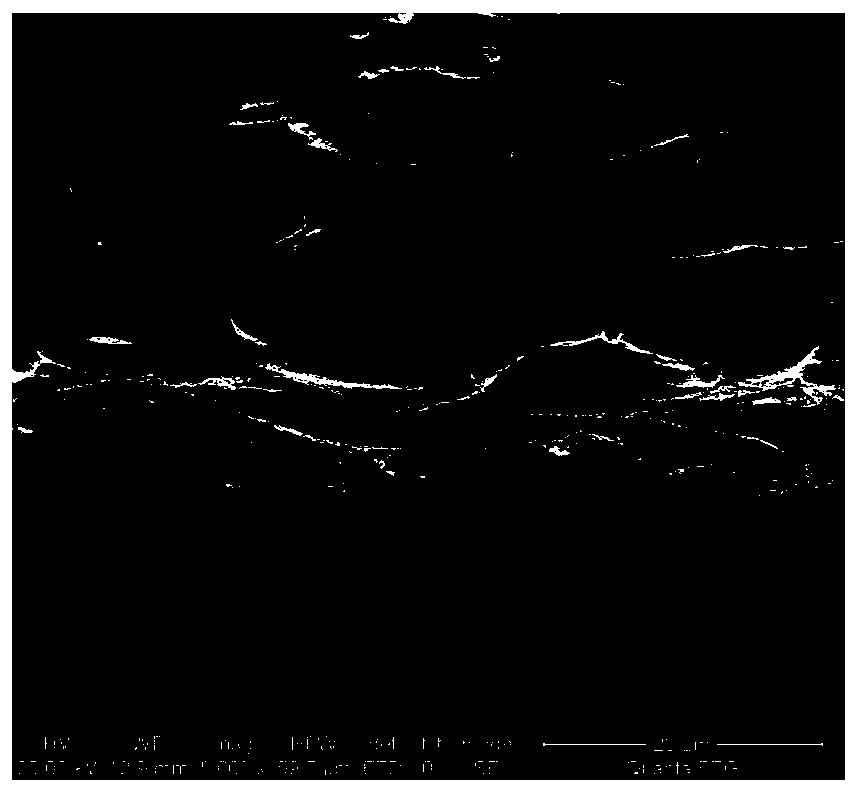

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 20g of PVDF to a mixed solvent of 64gDMF and 16g of acetone, stir and dissolve at 25°C for 24h, then let stand at 25°C for 48h to completely defoam, and finally obtain a spinning fiber with a mass concentration of 20%. liquid;

[0033] (2) Put the spinning solution into the syringe, and use a 0.8mm flat needle for electrospinning. The extrusion rate of the spinning solution is 1.0ml / h, the spinning voltage is 15kV, and the receiving distance from the top of the needle to the collector is 15 cm, the rotating speed of the collector is 300 rpm, the horizontal reciprocating speed of the flat needle along the roller direction of the collector is 1.0 cm / s, the spinning temperature is 25° C., and the relative humidity is 25% RH.

[0034] (3) m-phenylenediamine and ethylenediamine are dissolved in deionized water, and the mass concentration is 3.0% and 0.5%, respectively. As the first aqueous phase solution, trimesoyl chloride is dissolved in n-hexane, and the mass conc...

Embodiment 2

[0042] (1) Add 12g of Nylon to 70.4g of formic acid and 17.6g of dichloromethane, heat and stir to dissolve at 50°C for 12h, then let stand at 50°C for 12h to completely defoam, and finally obtain The spinning solution whose mass concentration is 12%;

[0043] (2) Put the spinning solution into the syringe, and use a 0.6mm flat needle for electrospinning. The extrusion rate of the spinning solution is 0.5ml / h, the spinning voltage is 25kV, and the receiving distance from the top of the needle to the collector is 8 cm, the rotational speed of the collector is 100 rpm, the horizontal reciprocating speed of the flat needle along the roller direction of the collector is 0.5 cm / s, the spinning temperature is 23° C., and the relative humidity is 15% RH.

[0044] (3) dissolving m-phenylenediamine in water with a mass concentration of 3.0%, fully stirring it as the first aqueous phase solution, dissolving trimesoyl chloride in n-heptane with a mass concentration of 0.10%, as the first...

Embodiment 3

[0052] (1) Add 15g of PVDF and 10g of PAN to 75g of DMAc, heat and stir to dissolve at 80°C for 6h, then let it stand at 80°C for 12h to completely defoam, and finally obtain a mass concentration of 25% spinning solution;

[0053] (2) Put the spinning solution into the syringe, and use a 1.0mm flat needle for electrospinning. The extrusion rate of the spinning solution is 2.0ml / h, the spinning voltage is 20kV, and the receiving distance from the top of the needle to the collector is 20 cm, the rotating speed of the collector is 500 rpm, the horizontal reciprocating speed of the flat needle along the roller direction of the collector is 2.0 cm / s, the spinning temperature is 28° C., and the relative humidity is 20% RH.

[0054] (3) m-phenylenediamine and hexamethylenediamine are dissolved in water, and the mass concentration is 4.0% and 1.0% respectively, as the first aqueous phase solution, trimesoyl chloride is dissolved in n-hexane, and the mass concentration is 0.50%, as Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com