A kind of preparation method of hydrophobic carbon point modified forward osmosis composite membrane

A hydrophobic, forward osmosis technology, applied in the field of membrane separation, can solve the problems of poor compatibility, large filler size, difficult to support layer modification, etc., achieve good compatibility, improve water flux, and alleviate the extreme concentration difference the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

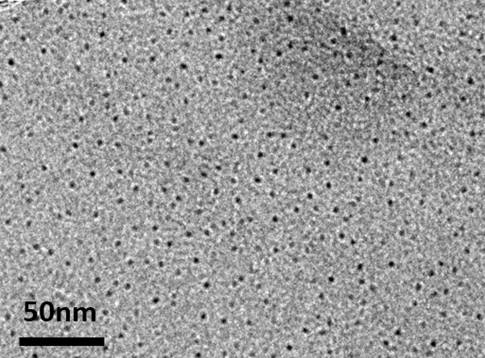

[0046] This example provides a porous polymer support layer modified with hydrophobic carbon dots, and hydrophobic carbon dots are distributed in the porous polymer support layer modified with hydrophobic carbon dots.

[0047] Wherein, the content of hydrophobic carbon dots is 5-15 wt%. The particle size of the hydrophobic carbon dots is 1-100 nm, preferably 2-5 nm.

Embodiment 2

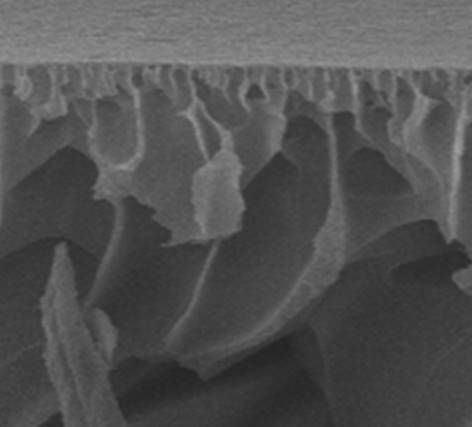

[0049] This example provides a forward osmosis composite membrane, including:

[0050] The hydrophobic carbon dot modified porous polymer support layer of Example 1; and the active layer covering the surface of the porous polymer support layer.

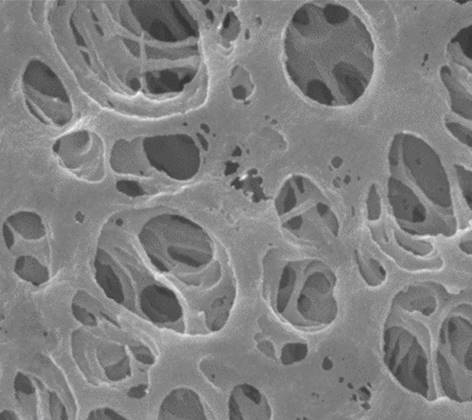

[0051] Wherein, the porosity of the forward osmosis composite membrane is 50-80%.

Embodiment 3

[0053] This example provides a method for preparing a forward osmosis composite membrane, including the following steps:

[0054] S1: Add strong base to aldehyde for reaction, after standing still, add inorganic acid to the reaction solution for neutralization, solid-liquid separation to obtain hydrophobic carbon dots;

[0055] S2: adding the hydrophobic carbon dots and film-forming agent prepared in step S1 into the organic solvent in sequence, and mixing to obtain the casting solution;

[0056] S3: defoaming and scraping the casting solution obtained in step S2 to obtain a porous polymer support layer modified by hydrophobic carbon dots;

[0057] S4: Put the porous polymer support layer modified by hydrophobic carbon dots obtained in step S3 into a coagulation bath, remove the aqueous solution on the surface of the support layer with a scraper after taking it out, and remove the porous polymer support layer modified by hydrophobic carbon dots One of the surfaces was contact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com