Preparation method of hydrophobic-carbon-dot-modified forward osmosis composite membrane

A hydrophobic, forward osmosis technology, applied in the field of membrane separation, can solve the problems of difficult-to-support layer modification, poor compatibility, large filler size, etc., to alleviate the internal concentration polarization, good compatibility, water flux boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

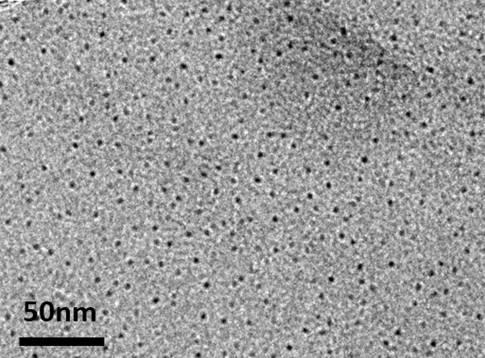

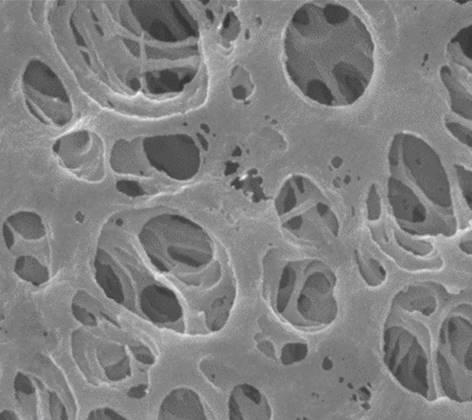

[0046] This example provides a porous polymer support layer modified with hydrophobic carbon dots, and hydrophobic carbon dots are distributed in the porous polymer support layer modified with hydrophobic carbon dots.

[0047] Among them, the content of hydrophobic carbon dots is 5-15 wt%. The particle size of the hydrophobic carbon dots is 1-100 nm, preferably 2-5 nm.

Embodiment 2

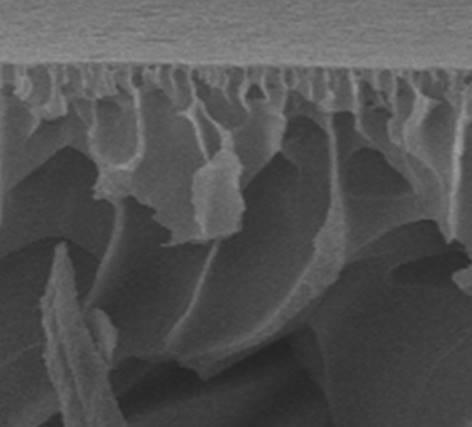

[0049] This example provides a forward osmosis composite membrane, including:

[0050] The hydrophobic carbon dot-modified porous polymer support layer of Example 1; and, an active layer covering the surface of the porous polymer support layer.

[0051] Among them, the porosity of the forward osmosis composite membrane is 50~80%.

Embodiment 3

[0053] This example provides a method for preparing a forward osmosis composite membrane, including the following steps:

[0054] S1: Add a strong base to the aldehyde for reaction, after standing still, add inorganic acid to the reaction solution for neutralization, and solid-liquid separation to obtain hydrophobic carbon dots;

[0055] S2: Add the hydrophobic carbon dots and the film-forming agent prepared in step S1 to the organic solvent in sequence, and obtain a casting liquid after mixing;

[0056] S3: Degas and scrape the casting liquid obtained in step S2 to obtain a porous polymer support layer modified with hydrophobic carbon dots;

[0057] S4: Put the porous polymer support layer modified with hydrophobic carbon dots obtained in step S3 into a coagulation bath, and after taking it out, remove the aqueous solution on the surface of the support layer with a scraper to remove the porous polymer support layer modified with hydrophobic carbon dots After contacting with the trime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com