PCCPEC pipeline for fluid conveying

A fluid transportation and pipeline technology, which is applied in the field of fluid transportation PCCPEC pipelines, can solve problems such as the inability to protect prestressed steel wires, and achieve the effects of avoiding hydrogen embrittlement broken wires, improving hydrogen embrittlement sensitivity, and avoiding hydrogen embrittlement broken wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

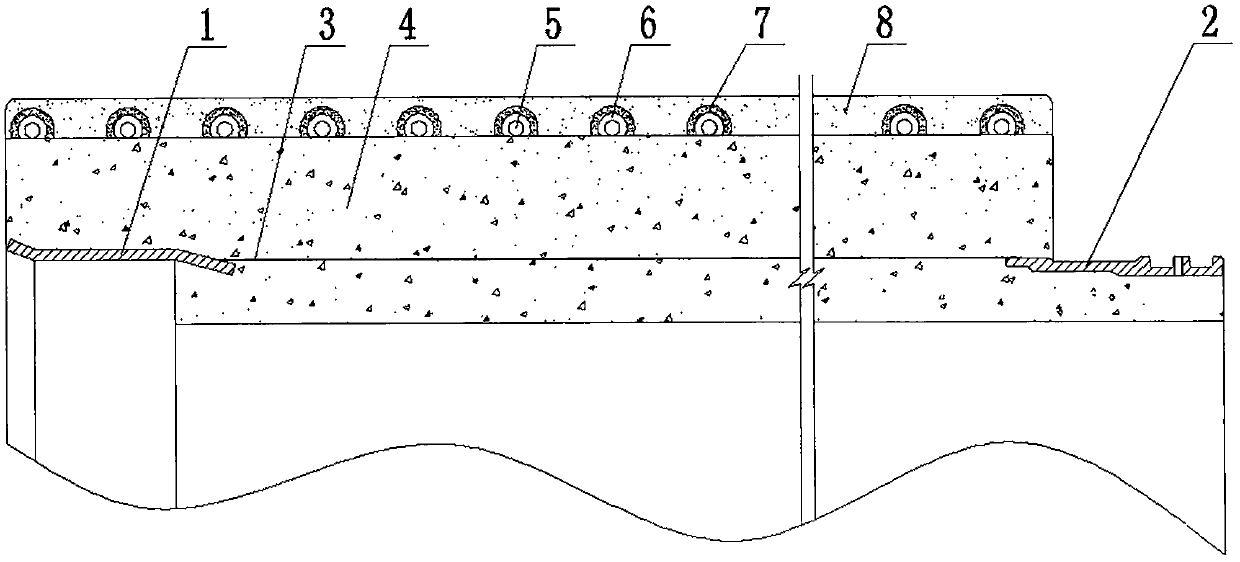

[0011] In the actual production process, the steel plate is made into a thin steel cylinder (3) by a steel cylinder welding machine, and then the socket steel ring (1) and the socket steel ring (2) are welded to both ends of the thin steel cylinder (3), Steel wire anchoring devices are welded on the socket steel ring (1) and the socket steel ring (2). After the steel mold is installed, the pipe core concrete (4) is poured inside and outside the thin steel cylinder (3) by vertical vibration method. After the strength required by the wire is wound on the outer wall of the prestressed steel wire (5), after the steel wire is wrapped, the polymer protective coating (6) is sprayed on the surface of the prestressed steel wire (5), and then the coarse sand protective body (7) is sprayed On the surface of the polymer protective coating (6), and finally on the roller shot mortar protective layer (8), a finished pipeline is formed, and is sent to the construction site after meeting the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com