Alkali-activated cementing material and preparation method thereof

A technology of cementitious materials and alkali excitation, applied in cement production and other directions, can solve problems such as limited source of raw materials, environmental pollution, waste of resources, etc., and achieve the effect of expanding comprehensive utilization of resources, expanding sources of raw materials, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

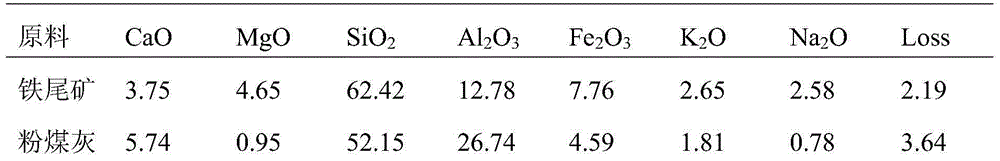

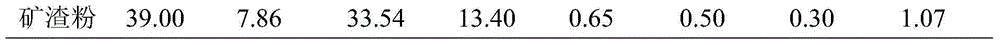

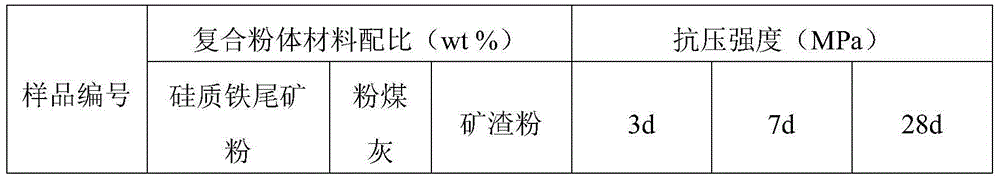

[0036] Example 1: Effects of different proportions of composite powder on the properties of alkali-activated gelling materials with iron tailings as the main raw material.

[0037] First, mix industrial water glass (water content 64%) with a modulus n of 3.3 and chemically pure NaOH at a weight ratio of 1:0.1, stir at room temperature to adjust the modulus n of the water glass to 1.5, and detect different proportions of the composite powder Influence on the mechanical properties of the clean slurry test piece of the alkali-activated gelling material, the preparation method of the alkali-activated gelling material of the present invention comprises the following steps:

[0038] After the raw ore of siliceous iron tailings is dried, it is ball-milled in a ball mill until the specific surface area is 350m 2 / kg.

[0039] The siliceous iron tailings powder, fly ash and slag powder obtained after grinding are mixed according to different proportions to obtain iron tailings powder-...

Embodiment 2

[0047] Example 2: The influence of the modulus and content of water glass on the performance of the alkali-activated gelling material with iron tailings as the main raw material.

[0048] First chemically pure NaOH is added in the undisturbed industrial water glass (modulus n=3.3) to adjust the modulus of water glass (the modulation ratio is shown in Table 3), and the modulus and content of detection water glass are paired with alkali-activated cementitious material clean slurry test Influence on the mechanical properties of parts, the preparation method of alkali-activated gelling material of the present invention comprises the following steps:

[0049] After the raw ore of siliceous iron tailings is dried, it is ball-milled in a ball mill until the specific surface area is 350m 2 / kg.

[0050] The siliceous iron tailing powder with a mass percentage of 50%, 35% of slag powder and 15% of fly ash are mixed to obtain a composite powder material of iron tailing powder-fly ash-s...

Embodiment 3

[0057] Example 3: The effect of water content on the properties of the alkali-activated cementitious material with iron tailings as the main raw material.

[0058] Mix industrial water glass (water content 64%) with a modulus n of 3.3 and chemically pure NaOH at a weight ratio of 1:0.1, stir at room temperature to adjust the modulus n of the water glass to 1.5, and test the alkali-induced gelation of different water-powder ratios The impact of material clean slurry test piece mechanical properties, the preparation method of alkali-activated gelling material of the present invention comprises the following steps:

[0059] After the raw ore of siliceous iron tailings is dried, it is ball-milled in a ball mill until the specific surface area is 350m 2 / kg.

[0060] The composite powder is obtained by mixing siliceous iron tailings powder with a mass percentage of 50%, slag powder with 35% and fly ash with 15%.

[0061] Water glass (Na 2 O nSiO 2 ) and different contents of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com