Wall body of steel frame filled with phosphogypsum-concrete composite wall and preparation method

A technology of concrete and phosphogypsum, applied in manufacturing tools, building materials, ceramic molding machines, etc., can solve the problems of increased production cost of wall panels, long concrete setting time, and reduced on-site construction efficiency, and achieves high economic and environmental protection dual value. , Delay entering the yield limit, and the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

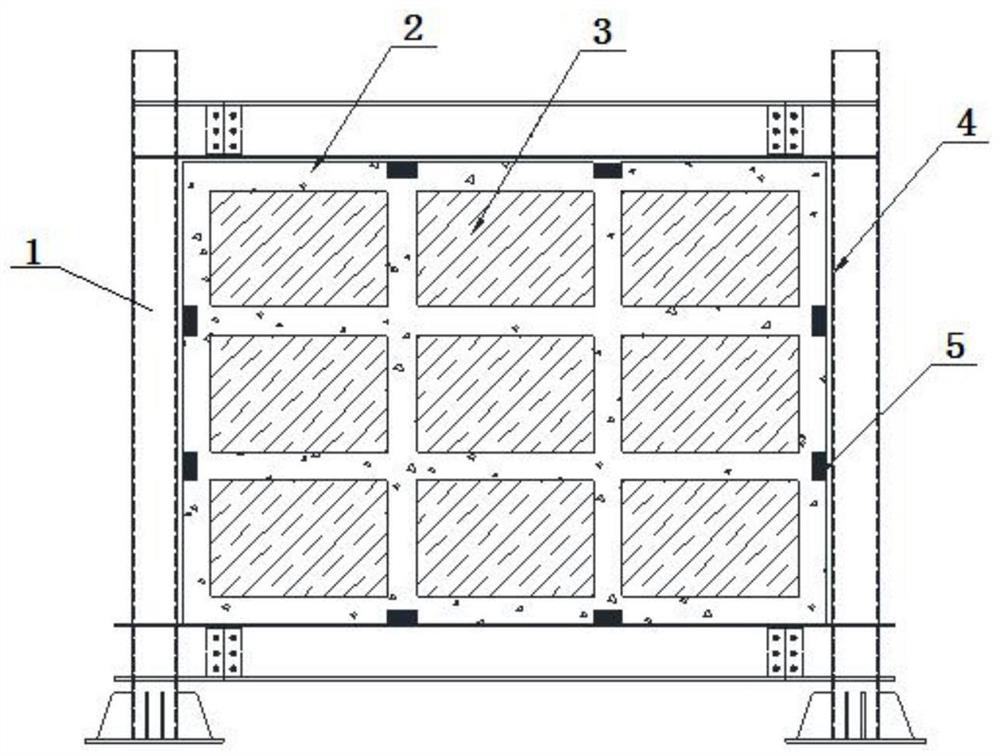

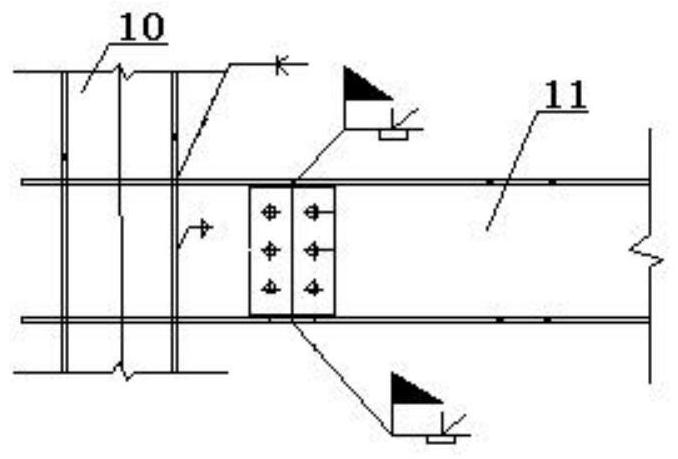

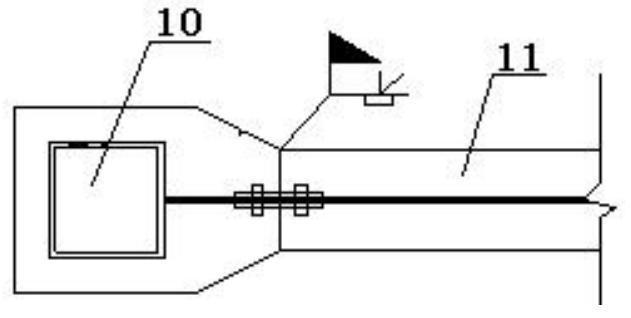

[0042] Such as Figure 1 to Figure 7 As shown, a wall body of a phosphogypsum-concrete composite wall filled with a steel frame according to the present invention includes a steel frame 1 and a phosphogypsum-concrete composite wall, and the phosphogypsum-concrete composite wall is installed in the steel frame 1 , a deformation joint 4 is left between the phosphogypsum-concrete composite wall and the steel frame 1, a flexible plate is installed in the deformation joint 4, and the steel frame 1 is at a position corresponding to the phosphogypsum-concrete composite wall Several clips 5 are welded, and the phosphogypsum-concrete composite wall includes a concrete frame 2 and a phosphogypsum-based composite cementitious material 3 filled in the concrete frame 2 . When in use, there are deformation joints 4 between the left side, the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com