Cementing materials with micro-expansion effect for mine filling

A technology of mine filling and cementitious materials, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as low utilization rate, pollute the environment, occupy fertile land, etc., and achieve good fluidity and high strength. and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

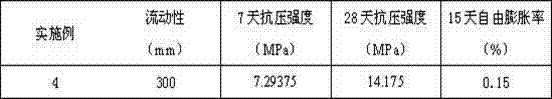

Embodiment 1

[0013] A kind of mine filling material with micro-expansion effect, its raw material composition and weight percentage are:

[0014] Steel slag: 70% Specific surface area: 590m 2 / kg

[0015] Slag: 20% Specific surface area: 520m 2 / kg

[0016] Desulfurization gypsum: 10%

[0017] Additional naphthalene-based water reducer: 0.5%

[0018] The following table shows the fluidity, compressive strength and micro-expansion results of the filling material prepared when the ratio of cementitious material to tailings is 1:4, mixed with water to a concentration of 75%. The micro-expansion of the filling material is tested with a concrete shrinkage dilatometer, and the fluidity is measured by the slump cylinder method in accordance with GB80-85 "Test Methods for Concrete Mixtures".

[0019]

[0020]

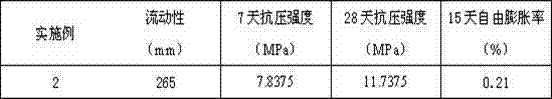

Embodiment 2

[0022] A kind of mine filling material with micro-expansion effect, its raw material composition and weight percentage are:

[0023] Steel slag: 63% Specific surface area: 590m 2 / kg

[0024] Slag: 25% Specific surface area: 520m 2 / kg

[0025] Desulfurization gypsum: 12%

[0026] Additional naphthalene-based water reducer: 0.5%

[0027] The following table shows the fluidity, compressive strength and micro-expansion results of the filling material prepared when the ratio of cementitious material to tailings is 1:4, mixed with water to a concentration of 75%.

[0028]

[0029]

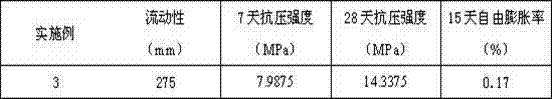

Embodiment 3

[0031] A kind of mine filling material with micro-expansion effect, its raw material composition and weight percentage are:

[0032] Steel slag: 48% Specific surface area: 590m 2 / kg

[0033] Slag: 40% Specific surface area: 480m 2 / kg

[0034] Desulfurization gypsum: 12%

[0035] Additional naphthalene-based water reducer: 0.5%

[0036] The following table shows the fluidity, compressive strength and micro-expansion results of the filling material prepared when the ratio of cementitious material to tailings is 1:4, mixed with water to a concentration of 75%.

[0037]

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com