Corrosion resistant water permeable brick

A permeable brick and corrosion-resistant technology, applied in the field of building materials, can solve the problems of poor salt corrosion resistance, high production cost, low production cost of cement-based permeable bricks, etc., and achieve good corrosion resistance and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

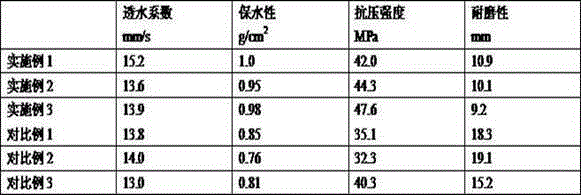

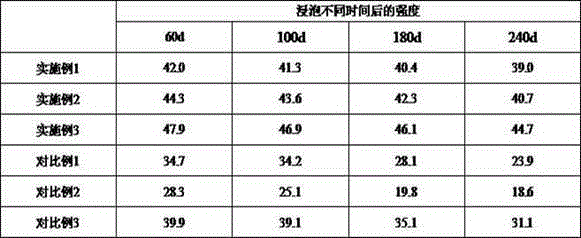

Embodiment 1

[0022] In this embodiment, the corrosion-resistant permeable brick is composed of 20wt% P.O42.5 cement, 1.2wt% anhydrite powder, 18.0wt% slag pellets, 12.0wt% hollow microspheres, 1.5 wt% admixture, and the balance of quartz sand. Wherein, the admixture contains: 20wt% water glass (modulus 2.2~2.5), 12.0wt% alkylphenol ether sulfosuccinate, 15.0wt% lignosulfonate, 3.0wt% γ-acryloxypropyltrimethoxysilane, 2.0wt% triglycidyl isocyanurate, 1.5wt% sodium dihydrogen phosphate, and the balance diethanolamine.

Embodiment 2

[0024] In this embodiment, the corrosion-resistant permeable brick is composed of 25wt% P.O42.5 cement, 1.0wt% anhydrite powder, 15.0wt% slag pellets, 10wt% hollow microspheres, 2.1wt% % of admixture, and the balance of quartz sand. Wherein, the admixture contains: 25wt% water glass (modulus 2.2~2.5), 15.0wt% alkylphenol ether sulfosuccinate, 12.0wt% lignosulfonate, 5.0wt% γ-methacryloxypropyltrimethoxysilane, 1.5wt% triglycidyl isocyanurate, 1.0wt% sodium dihydrogen phosphate, and the balance diethanolamine.

Embodiment 3

[0026] In this example, the corrosion-resistant permeable brick is composed of 22wt% P.O42.5 cement, 1.2wt% anhydrite powder, 18.0wt% slag pellets, 12wt% hollow microspheres, 1.8wt% % of admixture, and the balance of quartz sand. Wherein, the admixture contains: 22wt% water glass (modulus 2.2~2.5), 13.5wt% alkylphenol ether sulfosuccinate, 13.2wt% lignosulfonate, 4.0wt% γ-methacryloxypropyltrimethoxysilane, 1.8wt% triglycidyl isocyanurate, 1.2wt% sodium dihydrogen phosphate, and the balance diethanolamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com