Organic low-alkali setting accelerator capable of forming interpenetrating network structure as well as preparation method thereof

An interpenetrating network structure and quick-setting agent technology, applied in the field of building materials, can solve the problems of large proportion of fine aggregate, damage to the durability of concrete, and cracks, etc., to increase the flexural strength, improve the flexural strength, and improve the bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

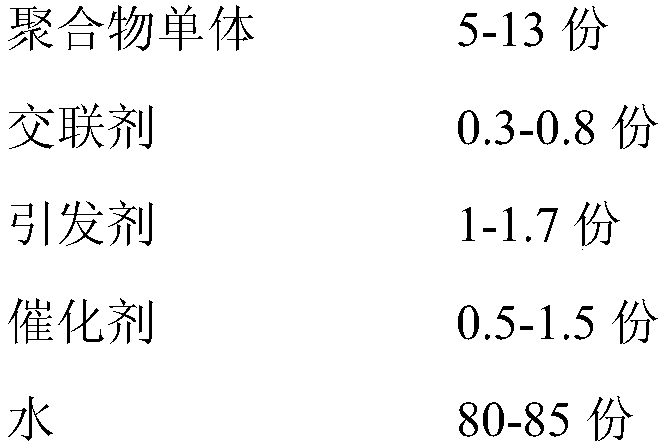

Method used

Image

Examples

preparation example Construction

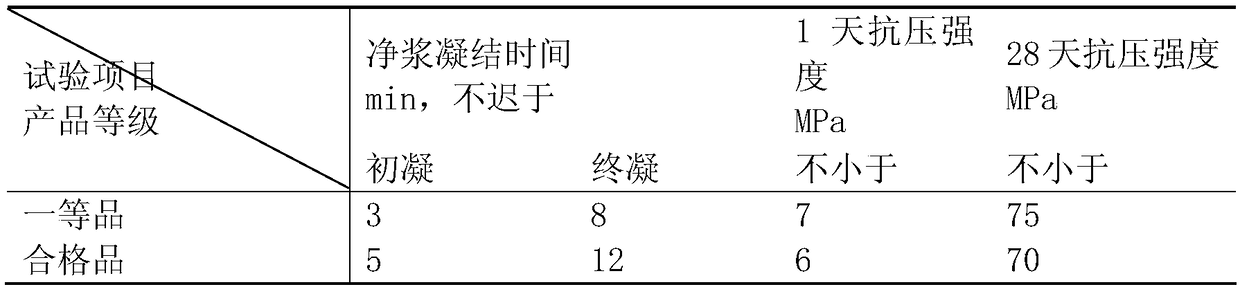

[0022] The preparation and maintenance of the concrete samples are designed according to the "Shotcrete Mix Design Method", and the compression samples are made according to GBJ82-85.

[0023] The mortar strength test is carried out according to the test method JC477-2005. Determine the flexural strength of mortar test blocks at different ages.

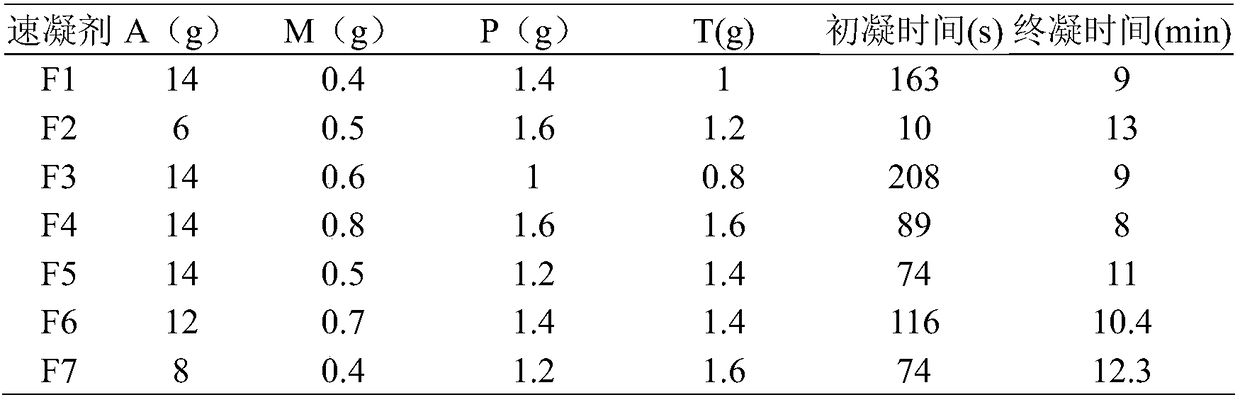

Embodiment 1

[0024] Implementation Example 1: Weigh 400g of cement, 160ml of water (W / C=0.4), divide the water into three parts of 100ml, 40ml, and 20ml and place them in three beakers, weigh 14g of acrylamide, N,N-methylene 0.4g of bisacrylamide, 1.4g of ammonium persulfate, 1g of N,N,N',N'-tetramethylethylenediamine; dissolve acrylamide and N,N-methylenebisacrylamide in 100ml of water In a beaker, dissolve ammonium persulfate in a beaker with 40ml of water, and dissolve N,N,N',N'-tetramethylethylenediamine in a beaker with 20ml of water. Pour the cement into the mixing pot of the slurry mixer, add acrylamide and N,N-methylenebisacrylamide solution, ammonium persulfate solution, N,N,N',N'-tetramethylethylenedi For the amine solution, stir and mix for 30 seconds, remove the stirring pot, and conduct subsequent coagulation time, flexural strength, and compressive strength tests. The national standard for mortar strength test requires a water-cement ratio of 0.5, which is achieved by changi...

Embodiment 2

[0025] Implementation Example 2: Weigh 400g of cement, 160ml of water (W / C=0.4), divide the water into three parts of 100ml, 40ml, and 20ml and place them in three beakers, weigh 6g of methacrylamide, N-methylol Acrylic acid 0.5g, potassium persulfate 1.6g, sodium bisulfite 1.2g; methacrylamide and N-methylol acrylic acid are dissolved in a beaker with 100ml of water, potassium persulfate is dissolved in a beaker with 40ml of water, Sodium bisulfite was dissolved in a beaker with 20ml of water. Pour the cement into the stirring pot of the slurry mixer, add methacrylamide and N-methylolacrylic acid solution, potassium persulfate solution, and sodium bisulfite solution in sequence, stir and mix for 30 seconds, remove the stirring pot, and carry out Follow-up setting time, flexural strength, compressive strength test. The national standard for mortar strength test requires a water-cement ratio of 0.5, which is achieved by changing the cement content to 320g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com