Bidirectional energy gathering tension shaping blasting cartridge

A blasting tube and energy-gathering technology, which is applied in blasting tubes, weapon accessories, offensive equipment, etc., can solve the problems of difficulty in ensuring the surrounding quality, and cannot completely eliminate the damage and destruction of the surrounding rock of the roadway, and achieves a high rate of peripheral eye marks and no damage. Low flatness, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

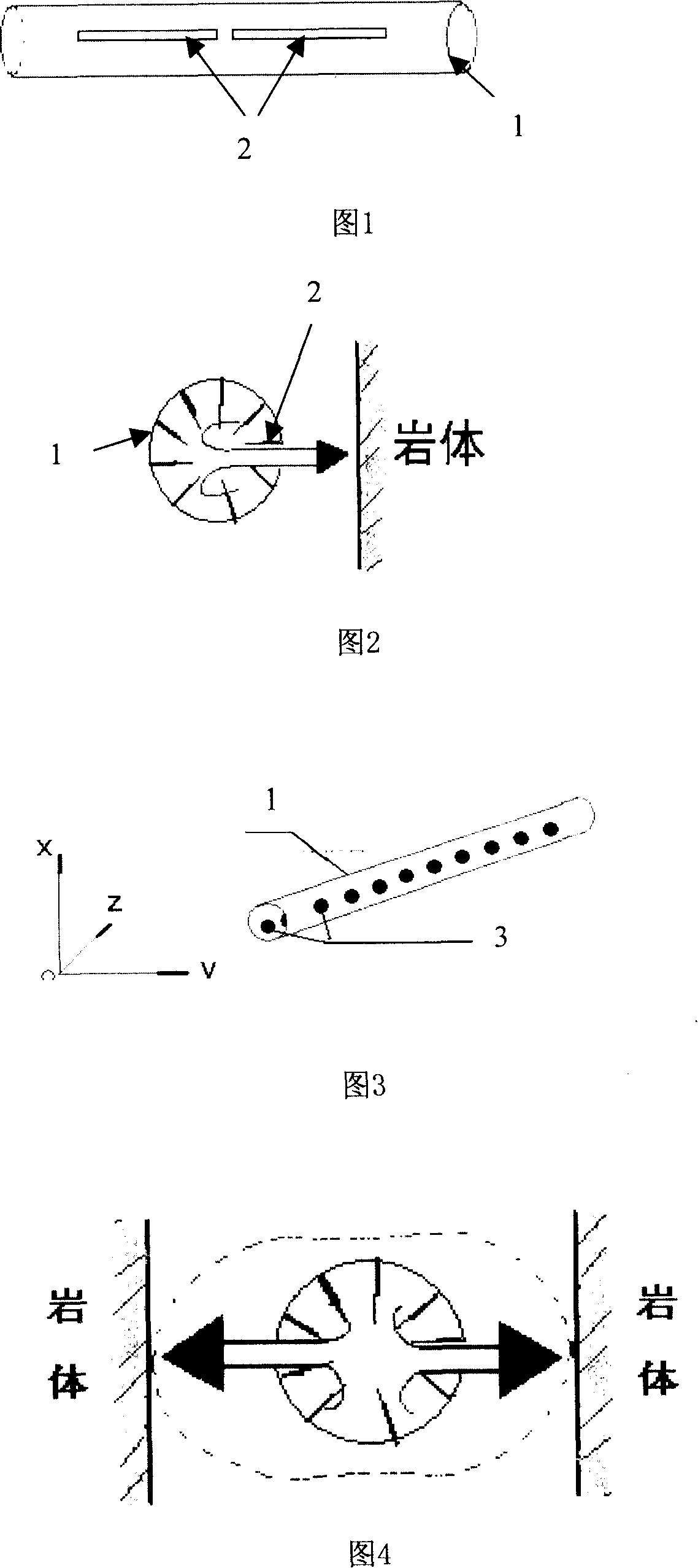

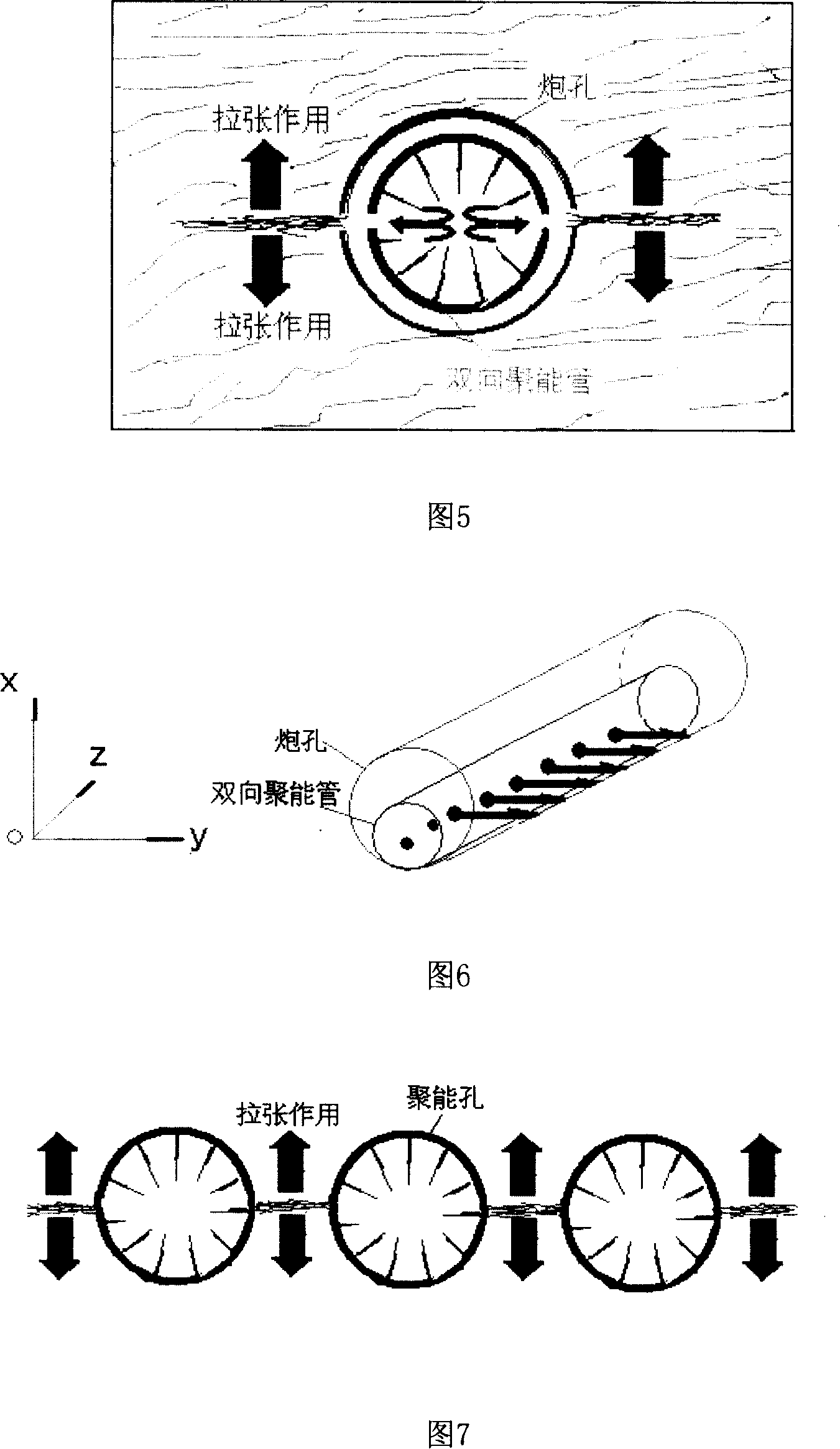

[0019] A two-way energy-gathering tensile forming blasting tube according to the present invention, its specific implementation method is: comprising a blasting tube body 1), consisting of an energy-gathering port 2 opened on the blasting tube body 1, and the energy-gathering port 2 is formed in the blasting tube body 1). Symmetrical energy-gathering holes are opened on both radial sides of the tube body 1 at an angle of 30°--180°, and:

[0020] 1) The blasting pipe body 1 is made of PVC pipe, whose diameter is 6-10mm smaller than the blast hole;

[0021] 2) The diameter of the energy gathering hole is 1 / 8-1 / 10 of the diameter of the blasting tube body 1;

[0022] 3) The distance of the energy gathering hole is 1 / 2-1 / 5 of the length of the blasting tube body 1;

[0023] The reason why the present invention achieves a better effect than before is that first of all, the effect of linear energy-concentrated blasting is limited for a body to be exploded with a high compressive st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com