Composite material road tie plate and assembling technique

A technology of composite materials and backing plates, applied in the field of building materials, can solve the problems of easy deformation, insufficient rigidity, poor soil quality, etc., and achieve the effect of simple and fast assembly, light weight and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

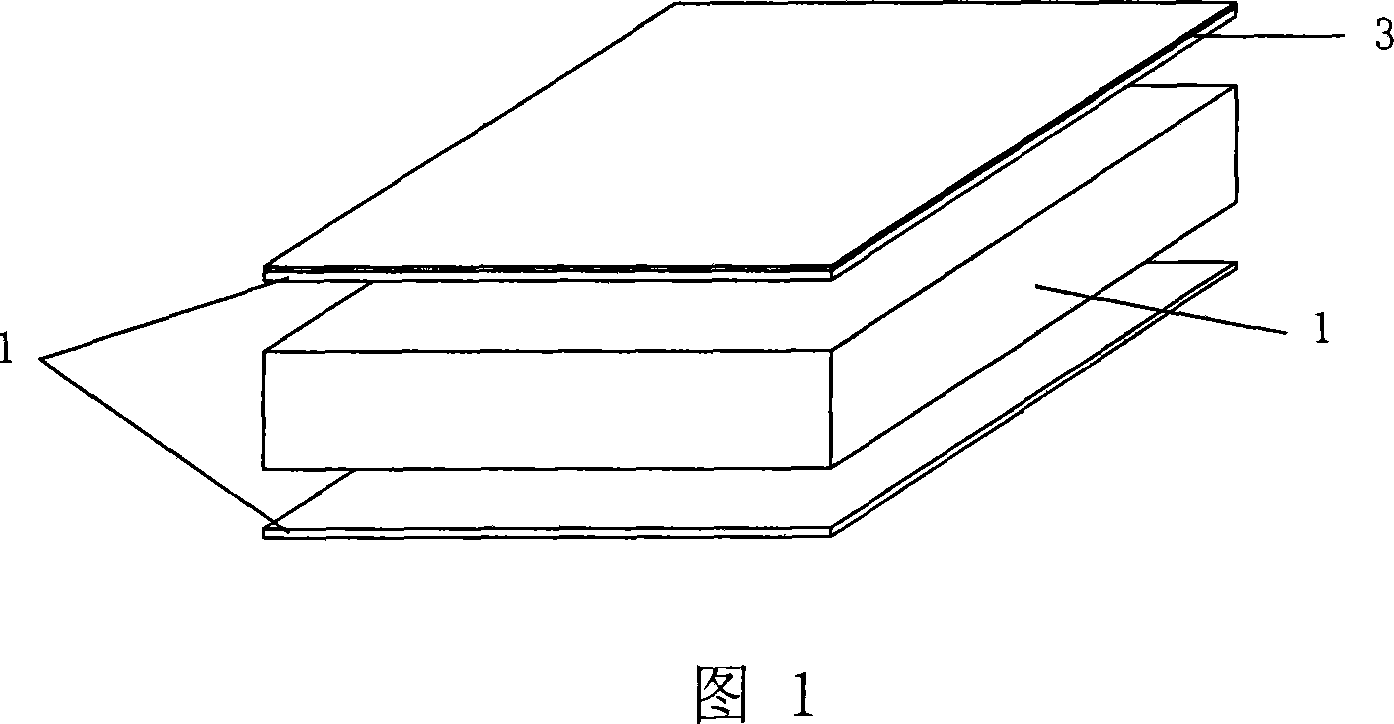

[0029] The composite pavement backing plate of the present invention comprises a core material 1 made of paulownia wood, and panels 2 are laid on both sides of the core material 1, and the panels 2 are formed by curing two layers of biaxial glass fiber cloth and phenolic resin. Prepared by a hand lay-up process, the upper surface of the panel 2 is coated with an anti-slip coating 3 mixed with emery and resin. The adjacent backing plates are connected by canvas 10, and the canvas 10 is nailed to the backing plates by rivets 11 in advance. When an emergency occurs, the backing plates can be directly unfolded to form a road.

Embodiment 2

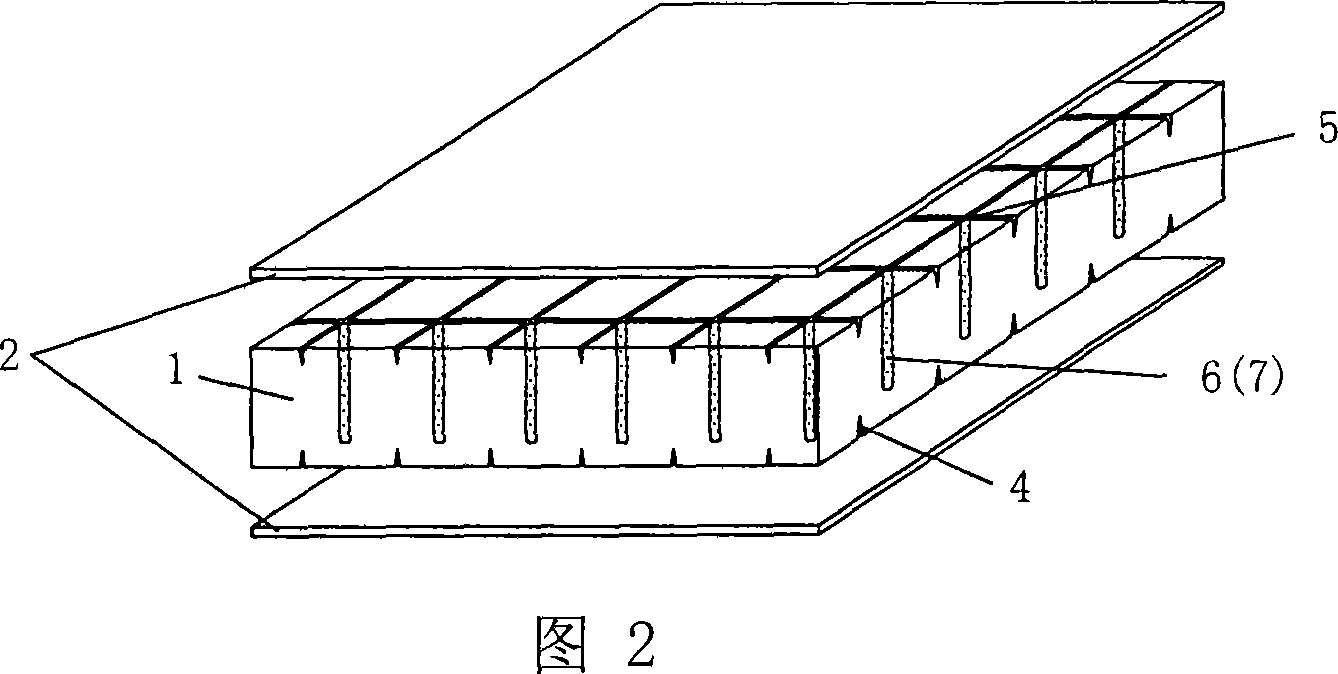

[0031] The composite pavement backing plate of the present invention comprises a core material 1 made of polyvinyl chloride foam, on the upper and lower surfaces of the core material 1 there are pointed grooves 4 arranged orthogonally, and at the intersection of the grooves 4 along the A circular perforation 5 is provided in the thickness direction of the core material 1, and a resin column 6 is formed after the resin is poured, and panels 2 are laid on both sides of the core material 1, and the panels 2 are made of four layers of four-axis glass fiber cloth and epoxy resin. It is made of cured resin and prepared by vacuum injection molding process. Boreholes 12 are reserved in advance on both side edges of backing plates, and iron chains 13 pass through the boreholes 12 to connect between adjacent backing plates.

Embodiment 3

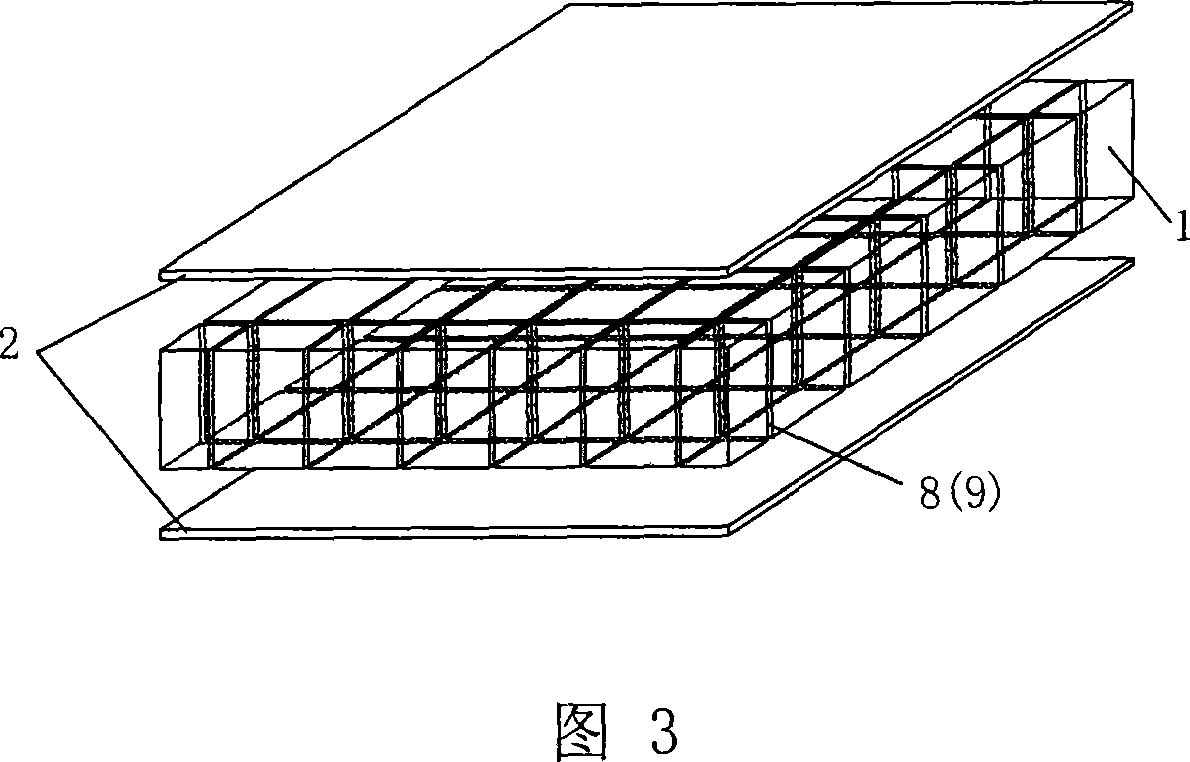

[0033] The composite pavement backing plate of the present invention comprises a core material 1 made of polyurethane foam, which is cut along the thickness direction of the core material 1, and the cut position is two-way orthogonal and vertically arranged, and glass fiber is filled in the cut position Fabric, filled with vinyl resin to form a composite material web 9, the panels 2 are laid on both sides of the core material 1, three layers of four-axis glass fiber cloth are laid on the upper surface, and five layers of four-axis fiberglass cloth are laid on the lower surface. Glass / carbon hybrid fiber cloth layer, backing plate two sides are provided with male and female connecting edge, and screw hole 14 is arranged on connecting edge, can make the male and female connecting edge of adjacent backing plate opposite, and adopt bolt 15 to pass through screw hole 14 to tighten.

[0034] There are various preparation methods for the above-mentioned composite pavement backing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com