Magnesium phosphate cement-base porous material and preparation method thereof

A magnesium phosphate cement and porous material technology, applied in the field of inorganic thermal insulation materials, can solve the problems of high foaming process requirements, low basalt activity, poor fire resistance, etc., and achieves good acid and alkali erosion resistance, good volume stability, crystallinity high energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

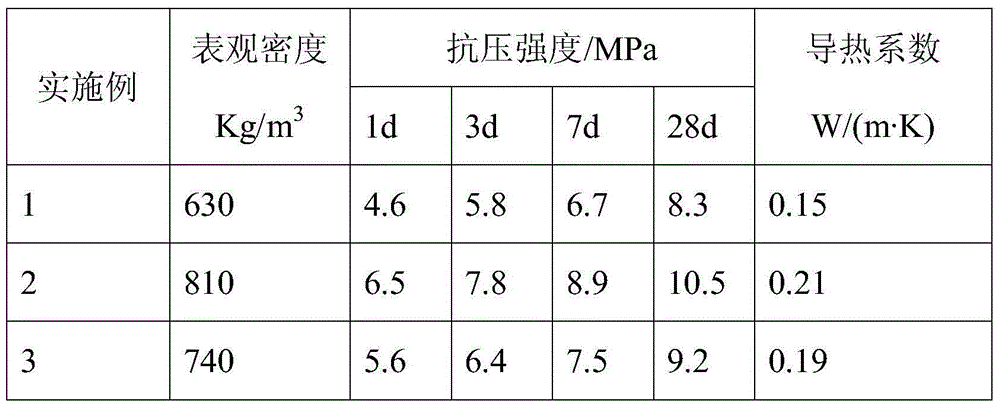

Embodiment 1

[0025] A preparation method of a magnesium phosphate cement-based porous material, the raw materials and parts by mass are composed of: 25 parts by mass of dead-burned magnesia, 25 parts by mass of ammonium dihydrogen phosphate, 10 parts by mass of borax, 50 parts by mass of fly ash, metal zinc Powder 0.6 parts by mass, and water 12 parts by mass; grind dead burnt magnesia to 10-50 μm (particle size, the same below), fly ash to 5-50 μm, and ammonium dihydrogen phosphate to 30-50 μm 150 μm, spare.

[0026]The method for preparing magnesium phosphate cement-based porous material is as follows: mix dead-burned magnesia, ammonium dihydrogen phosphate, borax, fly ash, and metal zinc powder evenly to form a mixed powder; put the mixed powder into a container with a stirring device Add water and start timing while adding water, according to slow stirring for 15s (stirring speed is 140-150 rpm), fast stirring for 1.5min (stirring speed is 275-295 rpm), stop (stop stirring ) for 15s, ...

Embodiment 2

[0028] A method for preparing a magnesium phosphate cement-based porous material. The raw materials and parts by mass are composed of: 35 parts by mass of dead-burned magnesia, 35 parts by mass of ammonium dihydrogen phosphate, 3 parts by mass of borax, 30 parts by mass of quartz sand, and metal iron powder 1 part by mass, and 16 parts by mass of water; grind dead burnt magnesia to 10-50 μm (particle size, the same below), grind fly ash to 5-50 μm, and ammonium dihydrogen phosphate to 30-150 μm ,spare.

[0029] The method for preparing magnesium phosphate cement-based porous material is as follows: mix dead-burned magnesia, ammonium dihydrogen phosphate, borax, quartz sand, and metal iron powder evenly to form a mixed powder; put the mixed powder into a container with a stirring device , then add water and start timing while adding water, according to slow stirring for 15s (stirring speed is 140-150 rpm), fast stirring for 1.5min (stirring speed is 275-295 rpm), stop (stop sti...

Embodiment 3

[0031] A method for preparing a magnesium phosphate cement-based porous material. The raw materials and parts by mass are composed of: 25 parts by mass of dead-burned magnesia, 25 parts by mass of ammonium dihydrogen phosphate, 2.5 parts by mass of borax, 30 parts by mass of fly ash, and quartz sand 20 parts by mass, 1 part by mass of metal zinc powder, and 13 parts by mass of water; grind dead-burned magnesia sand to 10-50 μm (particle size, the same below), fly ash and quartz sand to 5-50 μm respectively, Grind the ammonium dihydrogen phosphate to 30-150 μm and set aside.

[0032] The method for preparing magnesium phosphate cement-based porous material is as follows: mix dead-burned magnesia, ammonium dihydrogen phosphate, borax, fly ash, quartz sand, and metal zinc powder evenly to form a mixed powder; put the mixed powder into a stirring In the container of the device, add water and start timing while adding water, according to slow stirring for 15s (stirring speed is 140...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com