Preparation method of splash-proof coating barrel material for coating smearing

A paint bucket and anti-splash technology, applied in applications, household appliances, flat products, etc., can solve the problems of poor affinity between paint buckets and coatings, lack of anti-corrosion, coating environmental pollution, etc. Good acid and alkali corrosion resistance and the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

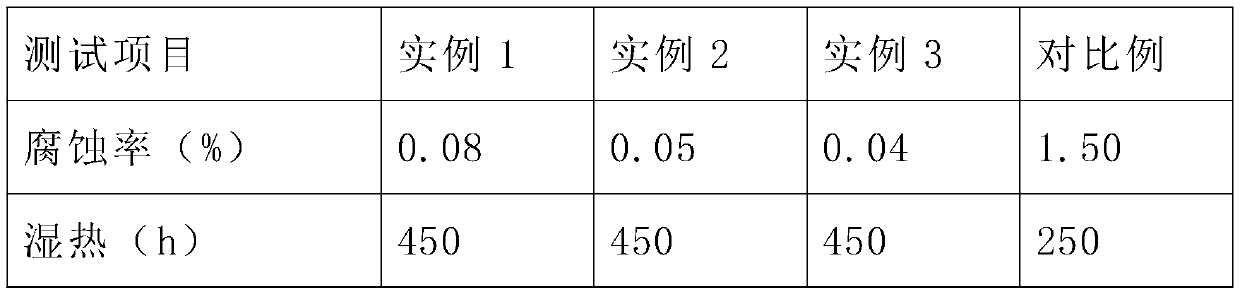

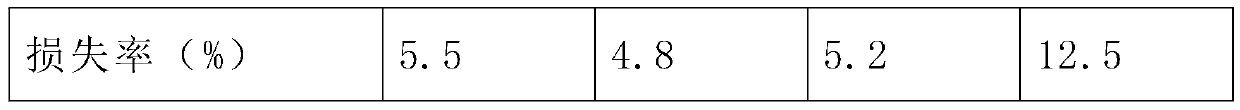

example 1

[0026] In parts by weight, 10 parts of nitrile rubber, 20 parts of ABS resin masterbatch, 30 parts of PET resin masterbatch, and 6 parts of polyaniline particles with a particle size of 2 mm were placed in a two-roll mixer, and the temperature of the front roller was After plasticizing under the conditions of 55°C, rear roll temperature of 50-55°C, and roll distance of 6mm, 10 parts of hydrotalcite and 4 parts of white carbon black were added to the two-roll mixer, mixed and plasticated to obtain conductive Plastic; in parts by weight, mix 50 parts of high-density polyethylene powder, 8 parts of conductive plastic, 10 parts of epoxidized soybean oil, 10 parts of EPDM raw rubber, 5 parts of zinc oxide, and 7 parts of aluminum stearate to obtain kneading The raw material is hot-pressed at a temperature of 70 ° C and a pressure of 1.2 MPa to form an outer plastic board. The molecular weight of the high-density polyethylene powder is 20,000, the crystallinity is 80%, and the ethyle...

example 2

[0028]In parts by weight, 13 parts of nitrile rubber, 25 parts of ABS resin masterbatch, 33 parts of PET resin masterbatch, and 7 parts of polyaniline particles with a particle size of 3 mm were placed in a two-roll mixer, and the temperature of the front roller was 58 ℃, the temperature of the rear roller is 52℃, and the roller distance is 7mm. After plasticizing, 11 parts of hydrotalcite and 5 parts of white carbon black are added to the twin-roll mixer, and mixed and plasticized to obtain a conductive plastic; by weight In terms of parts, 53 parts of high-density polyethylene powder, 9 parts of conductive plastic, 13 parts of epoxidized soybean oil, 11 parts of EPDM raw rubber, 8 parts of zinc oxide, and 8 parts of aluminum stearate are mixed to obtain mixing raw materials, and the temperature is The high-density polyethylene powder has a molecular weight of 40,000, a crystallinity of 83%, and an ethylene content of EPDM raw rubber of 53%; by weight Counting, add 33 parts o...

example 3

[0030] In parts by weight, 15 parts of nitrile rubber, 30 parts of ABS resin masterbatch, 35 parts of PET resin masterbatch, and 8 parts of polyaniline particles with a particle size of 3 mm were placed in a two-roll mixer, and the temperature of the front roller was After plasticizing at 60°C, the temperature of the rear roller is 55°C, and the roller distance is 8mm, 12 parts of hydrotalcite and 5 parts of white carbon black are added to the two-roll mixer, and mixed and plasticized to obtain a conductive plastic; press In parts by weight, 55 parts of high-density polyethylene powder, 10 parts of conductive plastics, 15 parts of epoxidized soybean oil, 12 parts of EPDM raw rubber, 10 parts of zinc oxide, and 8 parts of aluminum stearate are mixed to obtain mixing raw materials, and The temperature is 80°C and the pressure is 1.5MPa, and the outer plastic board is formed by hot pressing. The molecular weight of the high-density polyethylene powder is 50,000, the crystallinity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com