Preparation method of low-temperature dyeable composite elastic fiber

A composite elastic fiber, low temperature technology, used in fiber processing, conjugated synthetic polymer rayon, filament/thread forming, etc., can solve the problems of uneven stripes, uneven coloring, defective products, etc. The effect of uniform coloring, uniform color and good elasticity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

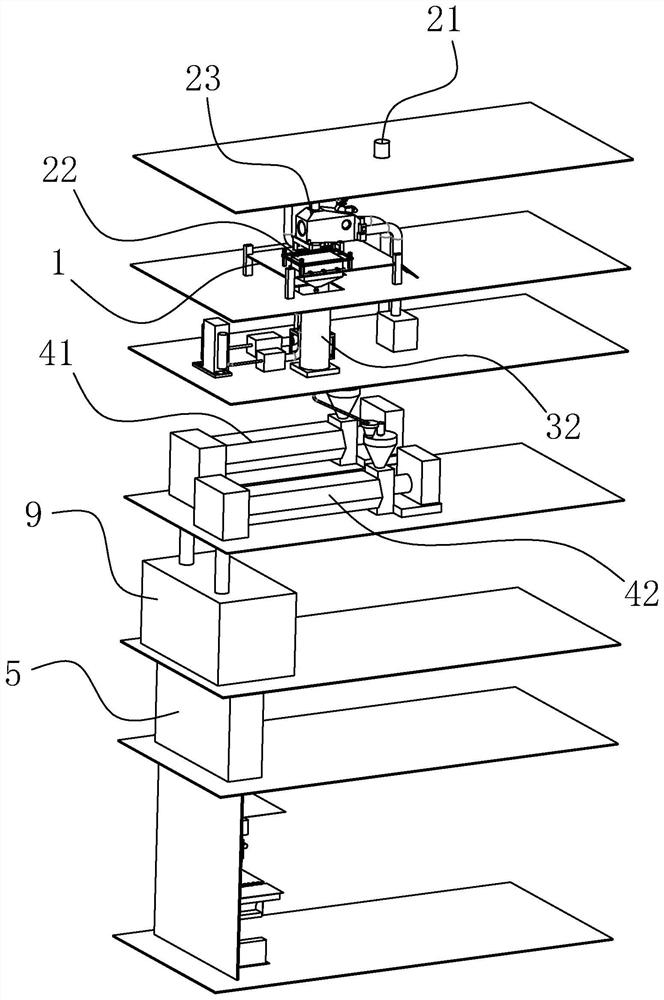

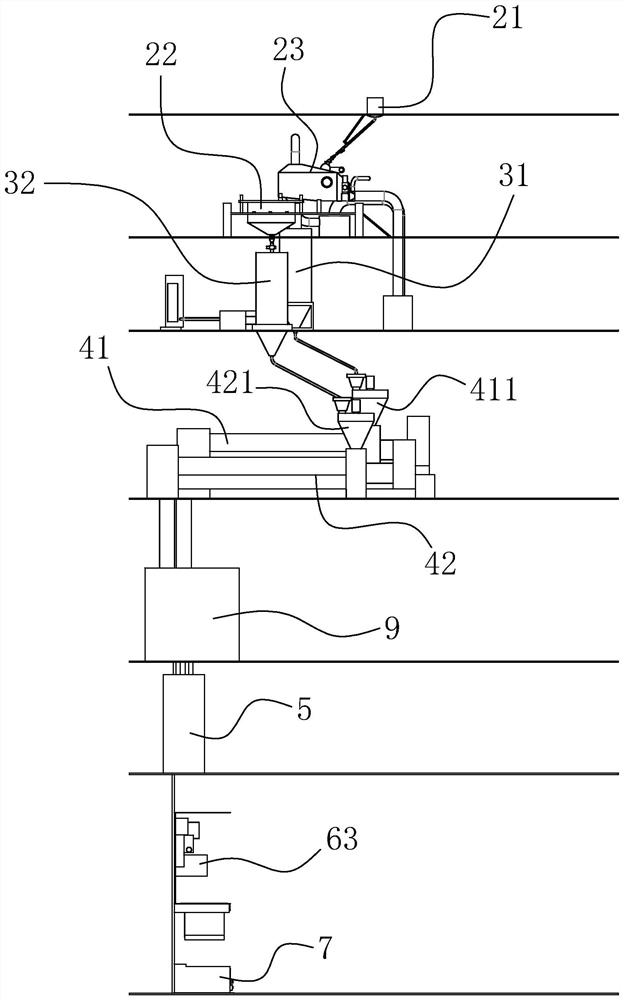

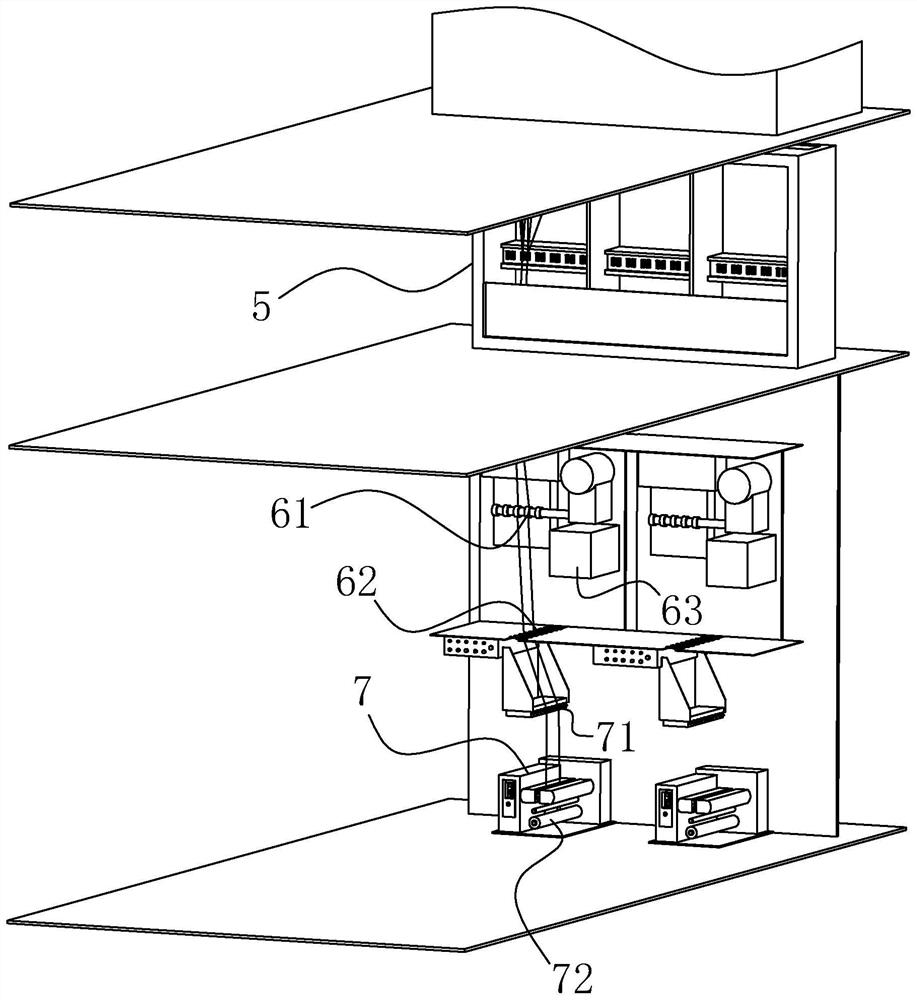

Image

Examples

Embodiment 1

[0044] (1) Using terephthalic acid, ethylene glycol isophthalate, ethylene glycol, and 1,4-butanediol as raw materials for the first step of esterification reaction, the feeding time is 3.0h, and the temperature is 255~ 258°C, the esterification rate is 95-96%; then add polyethylene glycol, and a composite stabilizer of triphenyl phosphate, organic silicon quaternary ammonium salt, and sodium acetate to carry out the second-step polycondensation reaction, and the reaction time in a low vacuum 50min, high vacuum reaction time 4.0h, polycondensation temperature 288-290°C, pressure not higher than 70Pa, obtained modified low-viscosity polyester slices dyed at low temperature and normal pressure, viscosity 0.47dl / g, as component A.

[0045] (2) Use 1,4-butanediol, terephthalic acid, catalyst and polyamide nucleating agent to carry out esterification (temperature 240-242°C, pressure 40-45KPa, residence time 2.5-3.0h), pre- Polycondensation (temperature 242-244°C, pressure 1.5-2.0KP...

Embodiment 2

[0049] (1) Using terephthalic acid, dihydroxyethyl isophthalate-5-sodium sulfonate, isophthalic acid, ethylene glycol, and 1,3-propanediol as raw materials for the first-step esterification reaction, the feed The time is 3.5h, the temperature is 257-258°C, and the esterification rate is 94-95%; then polyoxypropylene glycol, and a composite stabilizer of triphenyl phosphate, organic silicon quaternary ammonium salt and sodium acetate are added to carry out In the second step of polycondensation reaction, low vacuum reaction time is 50min, high vacuum reaction time is 4.5h, polycondensation temperature is 288-290°C, pressure is not higher than 70Pa, and modified low-viscosity polyester chips dyed at low temperature and normal pressure are obtained, with a viscosity of 0.49dl / g, as component A.

[0050] (2) Use 1,4-butanediol, terephthalic acid, catalyst and polyamide nucleating agent to carry out esterification (temperature 240-242°C, pressure 40-45KPa, residence time 2.5-3.0h)...

Embodiment 3

[0054] (1) Using terephthalic acid, diethyl isophthalate, sebacic acid, ethylene glycol, and 1,6-hexanediol as raw materials for the first step of esterification reaction, the feeding time is 4.0h, and the temperature The temperature is 255-256°C, and the esterification rate is 92-93%; then polytetrahydrofuran diol, and a composite stabilizer of triphenyl phosphate, organic silicon quaternary ammonium salt and sodium acetate are added to carry out the second-step polycondensation reaction, low The vacuum reaction time is 50 minutes, the high vacuum reaction time is 5.0 hours, the polycondensation temperature is 288-290 ° C, and the pressure is not higher than 70 Pa. The modified low-viscosity polyester chips dyed at low temperature and normal pressure with a viscosity of 0.54 dl / g are obtained as component A.

[0055] (2) Use 1,4-butanediol, terephthalic acid, catalyst and polyamide nucleating agent to carry out esterification (temperature 240-242°C, pressure 40-45KPa, residenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com