Ceramsite with lipophilic characteristic and preparation method of ceramsite

A technology of ceramsite and characteristics, which is applied in the field of ceramsite with lipophilic properties and its preparation, can solve the problems of not having oleophilic properties, increasing the strength of ceramsite, reducing the sintering temperature, etc., so as to save the traditional preparation of ceramsite, enhance Good degreasing performance and good acid and alkali corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

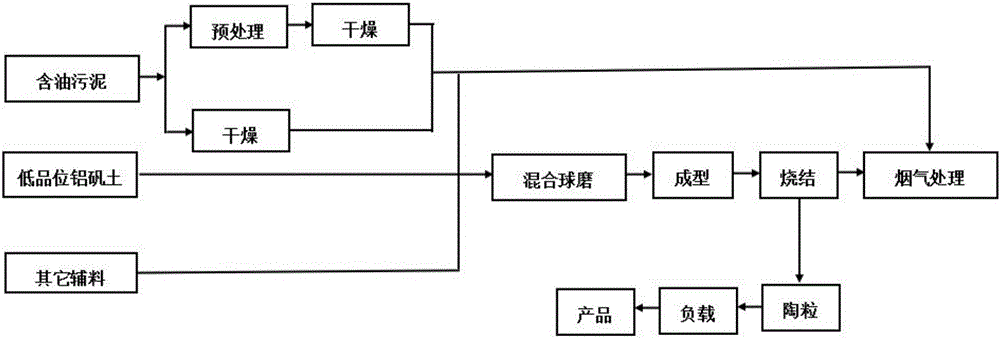

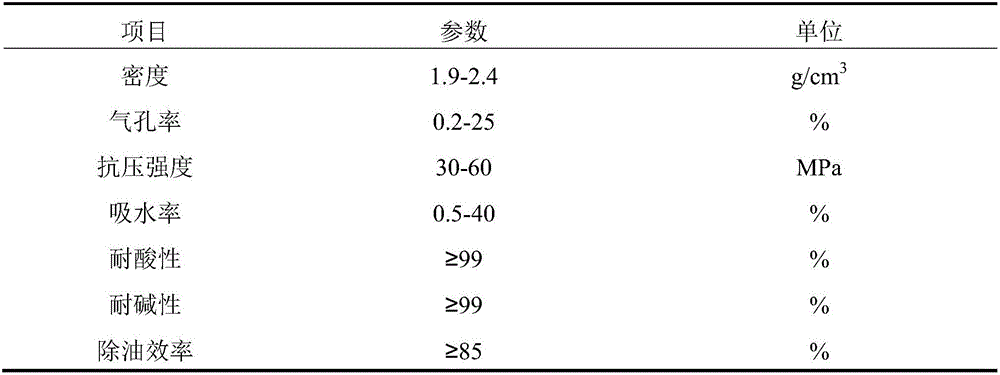

[0037] A ceramsite with lipophilic properties, which is mainly composed of oily sludge, bauxite, potassium feldspar, and bentonite, and the raw materials are calculated in parts by mass: 60 parts of oily sludge with a moisture content of 3% after pretreatment , 20 parts of low-grade bauxite, 15 parts of potassium feldspar, and 5 parts of bentonite.

[0038] The preparation method of the above-mentioned ceramsite with lipophilic properties, it may further comprise the steps:

[0039] (1) Select the oily sludge produced by oil field exploitation and transportation, and perform pretreatment such as dehydration, drying or cracking, incineration, etc., and the moisture content of the pretreated oily sludge is controlled at 3%;

[0040] (2) Pretreated oily sludge, low-grade bauxite, potassium feldspar, and bentonite are mixed and ball-milled at a weight ratio of 60:20:15:5, and the ball-milled material passes through a 200-mesh screen;

[0041] (3) The material after ball milling and...

Embodiment 2

[0046] A ceramsite with lipophilic properties, which is mainly composed of oily sludge, bauxite, potassium feldspar, bentonite, and glass powder. The raw materials are calculated in parts by mass: oily dirt with a moisture content of 6% after pretreatment 45 parts of mud, 35 parts of low-grade bauxite, 10 parts of potassium feldspar, and 10 parts of bentonite; glass powder is added in the form of additives, and the added amount of glass powder accounts for 15% of the total weight of other raw materials.

[0047] The preparation method of the above-mentioned ceramsite with lipophilic properties, it may further comprise the steps:

[0048] (1) Select the oily sludge, first perform pretreatments such as dehydration, drying or cracking, incineration, etc., and the moisture content of the pretreated oily sludge is controlled at 6%;

[0049] (2) After pretreatment, oily sludge, low-grade bauxite, potassium feldspar, and bentonite are mixed in a weight ratio of 45:35:10:10, and waste...

Embodiment 3

[0055] A ceramsite with lipophilic properties, which is mainly composed of oily sludge, bauxite, potassium feldspar, bentonite, and glass powder. The raw materials are calculated in parts by mass: oily dirt with a moisture content of 5% after pretreatment 30 parts of mud, 40 parts of low-grade bauxite, 20 parts of potassium feldspar, and 10 parts of bentonite; glass powder is added in the form of additives, and the added amount of glass powder accounts for 20% of the total weight of other raw materials.

[0056] The preparation method of the above-mentioned ceramsite with lipophilic properties, it may further comprise the steps:

[0057] (1) Select the oily sludge, first perform pretreatments such as dehydration, drying or cracking, incineration, etc., and the moisture content of the pretreated oily sludge is controlled at 5%;

[0058] (2) After pretreatment, oily sludge, low-grade bauxite, potassium feldspar, and bentonite are mixed in a weight ratio of 30:40:20:10, and waste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com