High-toughness epoxy composite grouting material capable of being constructed at low temperature and preparation method thereof

A grouting material and high toughness technology, applied in the field of high toughness epoxy composite grouting material and its preparation, can solve the problems of high temperature sensitivity, debonding, low early strength and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

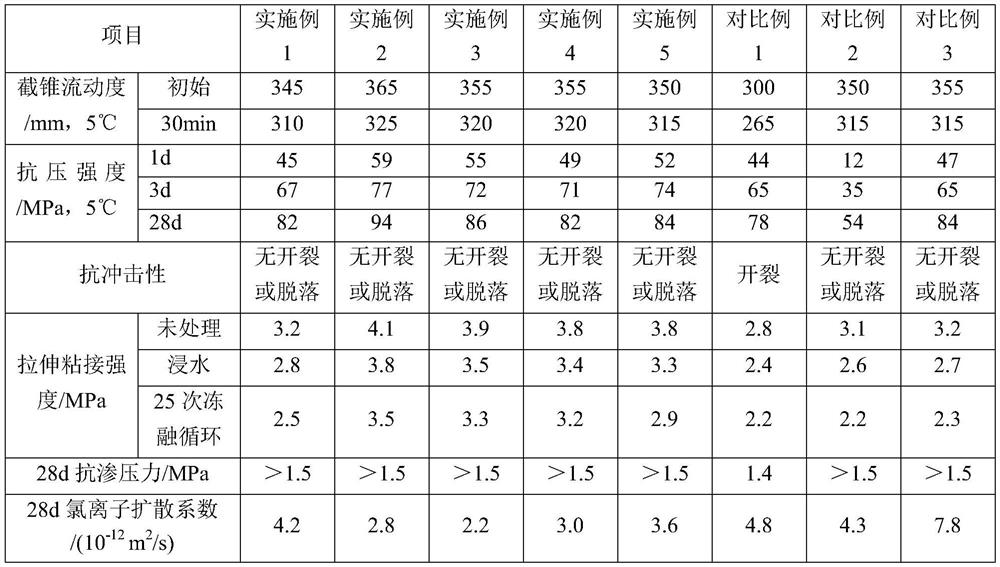

Examples

Embodiment 1

[0031] A high-toughness epoxy composite grouting material capable of low-temperature construction, prepared by the following method:

[0032] (1) Stir 50 parts of water-based epoxy resin and 30 parts of styrene-butadiene emulsion in a beaker at a speed of 160 r / min, add 1 part of polyether-modified polydimethylsiloxane dropwise, and let stand until the bubbles disappear, Obtain A component;

[0033] (2) take by weighing 50 parts of curing agent, add 4 parts of dipropylene glycol methyl ether and 83 parts of water successively, and obtain B component after stirring at a rotating speed of 400r / min;

[0034] (3) Weigh 550 parts of modified cement powder, 1 part of lithium carbonate, 2 parts of tartaric acid, 2 parts of polycarboxylate powder water reducing agent, 35 parts of alkali-resistant glass flakes, and 500 parts of 100-mesh quartz sand, mixed and placed in a mixer Stir evenly at a rotating speed of 120r / min to obtain component C;

[0035] (4) First, the A component and t...

Embodiment 2

[0038] A high-toughness epoxy composite grouting material capable of low-temperature construction, prepared by the following method:

[0039] (1) Stir 70 parts of water-based epoxy resin and 30 parts of styrene-butadiene emulsion in a beaker evenly at a rotating speed of 180 r / min, add 3 parts of polysiloxane dropwise, and let stand until the bubbles disappear to obtain component A;

[0040] (2) take by weighing 70 parts of curing agent, add 7 parts of dipropylene glycol butyl ether and 92 parts of water successively, and obtain B component after stirring at a rotating speed of 450r / min;

[0041](3) Weigh 680 parts of modified cement powder, 1.5 parts of lithium sulfate, 3 parts of boric acid, 4 parts of polycarboxylic acid powder water reducing agent, 40 parts of alkali-resistant glass flakes, and 700 parts of 100-mesh quartz sand and mix them in a mixer Stir evenly at a rotating speed of 150r / min to obtain component C;

[0042] (4) First, the A component and the B component...

Embodiment 3

[0045] A high-toughness epoxy composite grouting material capable of low-temperature construction, prepared by the following method:

[0046] (1) Stir 60 parts of water-based epoxy resin and 40 parts of styrene-butadiene emulsion in a beaker at a rotating speed of 200 r / min, add 2 parts of silicon oxide polyether dropwise, and let stand until the bubbles disappear to obtain component A;

[0047] (2) take by weighing 60 parts of curing agent, add 6 parts of propylene glycol phenyl ether and 91 parts of water successively, and obtain B component after stirring at a rotating speed of 500r / min;

[0048] (3) Weigh 650 parts of modified cement powder, 1 part of lithium chloride, 2 parts of sodium citrate, 3 parts of polycarboxylic acid powder water reducing agent, 55 parts of alkali-resistant glass flakes, and 600 parts of 120-mesh quartz sand and mixed Place in a mixer and stir evenly at a rotating speed of 150r / min to obtain component C;

[0049] (4) First, the A component and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com