Multi-component concrete composite repair mortar

A technology for repairing mortar and concrete, which is applied in the field of building materials, and can solve the problems affecting the normal use of buildings and the long maintenance time of ordinary concrete construction, and achieve the effects of strong construction adaptability, high early strength and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

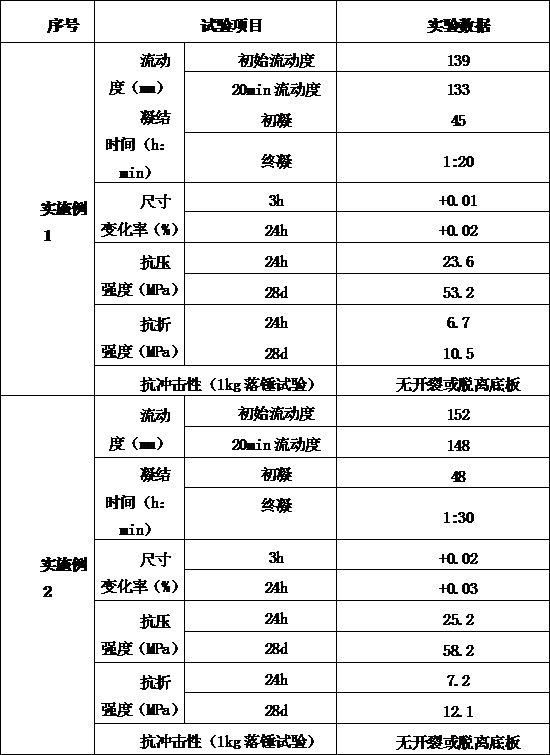

Examples

Embodiment 1

[0012] Example 1: The multi-component concrete composite repair mortar of the present invention is prepared by mixing dry powder of a multi-component concrete composite repair mortar with water. The content of each component in the dry powder of multi-component concrete composite repair mortar is calculated in parts by weight:

[0013] Portland cement 24.00

[0014] Sulphoaluminate cement 7.00

[0015] Ash Calcium 1.50

[0016] Anhydrite 2.50

[0017] Quartz sand 43.81

[0018] Ultrafine fly ash 15.00

[0019] Silica fume 5.00

[0020] Plastic expansion agent 0.01

[0021] Water reducer 0.20

[0022] Redispersible latex powder 0.80

[0024] Defoamer 0.10

[0025] Stable thickener 0.03

[0026] Mix the above materials evenly to obtain a multi-component concrete composite repair mortar dry powder, mix it with water at a ratio of 0.13 to the water-material ratio, and use a mixer to mix and stir for 3-5 minutes to make a multi-component c...

Embodiment 2

[0027] Embodiment 2: The multi-component concrete composite repair mortar of the present invention is prepared by mixing dry powder of a multi-component concrete composite repair mortar with water. The content of each component in a multi-component concrete composite repair mortar dry powder is calculated in parts by weight:

[0028] Portland cement 22.00

[0029] High alumina cement 8.00

[0030] Anhydrite 8.00

[0031] Quartz sand 39.67

[0032] heavy calcium 20.00

[0033] Polycarboxylate superplasticizer 0.30

[0034] Redispersible latex powder 1.00

[0035] Stable thickener 0.03

[0036] Tartaric acid 0.40

[0037] Ca(OH)2 0.50

[0038] Defoamer 0.10

[0039] Mix the above materials evenly to obtain a multi-component concrete composite repair mortar dry powder, mix it with water at a ratio of 0.14 to the water-material ratio, and use a mixer to mix and stir for 3-5 minutes to make a multi-component concrete composite repair mortar .

[0040] Table 1 is a kind o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com