A super high water filling material

A filling material and ultra-high water technology, applied in the field of mine filling, can solve the problems of low strength and long initial setting time, and achieve the effects of stable performance, good fluidity and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

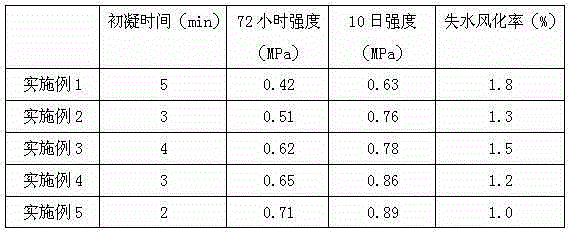

Examples

Embodiment 1

[0033] Component A: calcium sulfoaluminate 45Kg, calcium aluminate 44Kg, calcium carbonate 2Kg, sodium carbonate 8Kg, polyacrylamide 0.5Kg, sodium hydroxymethyl cellulose 0.5Kg.

[0034] Component B: Calcium Sulfate 70Kg, Calcium Oxide: 24Kg, Calcium Metaaluminate 5Kg, Calcium Chloride 1Kg.

Embodiment 2

[0036] Component A: calcium sulfoaluminate 75Kg, calcium aluminate 15Kg, calcium carbonate 4Kg, sodium carbonate 2Kg, polyacrylamide 2Kg, sodium hydroxymethyl cellulose 2Kg.

[0037] Component B: calcium sulfate 88Kg, calcium oxide 8Kg, sodium metaaluminate 1Kg, calcium chloride 3Kg.

Embodiment 3

[0039] Component A: calcium sulfoaluminate 48Kg, calcium aluminate 40Kg, calcium carbonate 3Kg, sodium carbonate 7Kg, polyacrylamide 1Kg, sodium hydroxymethyl cellulose 1Kg.

[0040] Component B: calcium sulfate 73Kg, calcium oxide 22Kg, sodium metaaluminate 3Kg, calcium chloride 2Kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com