Upward spacing admission passage filling mining method

A technology of approach filling and mining method, which is applied in the direction of filling, ground mining, mining equipment, etc., and can solve problems such as stope mining work interruption, restriction, and reduction of ore block production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

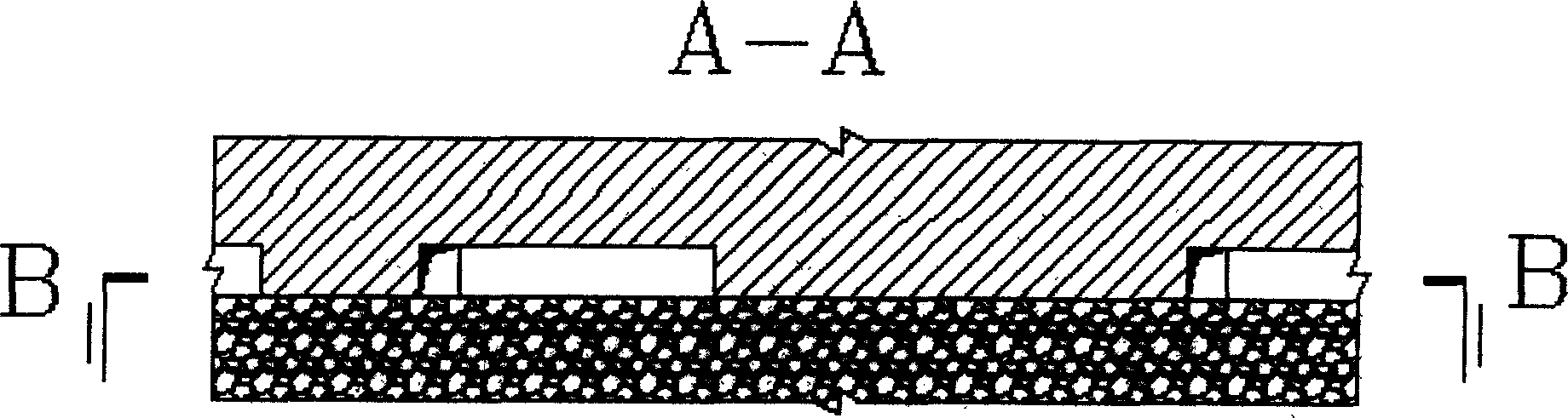

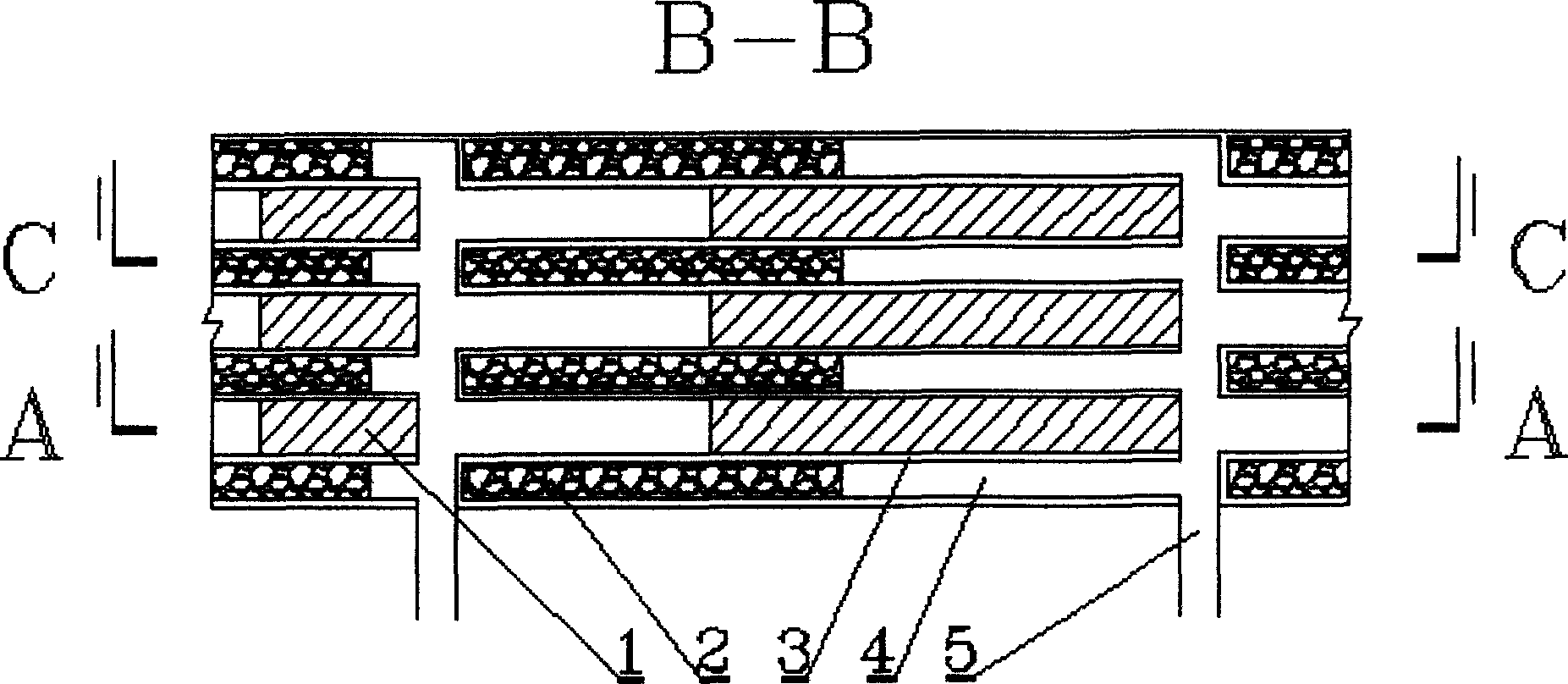

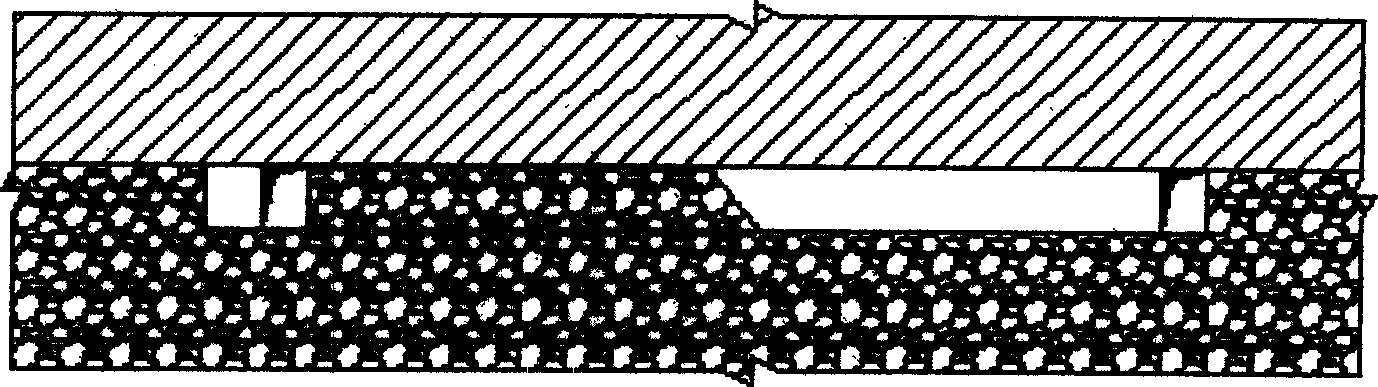

Method used

Image

Examples

Embodiment Construction

[0028] Supporting is undoubtedly required to excavate roadways in unstable ore bodies for mining operations. The support of the first phase recovery approach is temporary. When the primary cemented filling is completed, the role of temporary support will disappear. Temporary support is helpless waste. In order to avoid this waste, it should be considered that the primary support can be utilized by the primary filling.

[0029] The present invention also needs to carry out necessary support in order to ensure the safety of the first-phase mining operation. There are various support methods, building walls and setting up sheds is a simple and practical support method, and can be a part of the first-stage filling. With the formation of the first-stage mining approach, walls and roofs were built on its two sides. In the first phase of goaf, cemented filling is not used, but dry filling is adopted. The wall and the filling in the wall form the filling body, which supports the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com