Solid-waste-based high-iron sulphoaluminate maritime work cementing material as well as preparation method and application thereof

A technology of high iron sulfoaluminate and cementitious materials, applied in the field of resource recycling industry, can solve the problems of poor seawater erosion resistance, low early strength, and low service life, achieve excellent carbonation resistance, and increase durability and life , Excellent anti-wave erosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

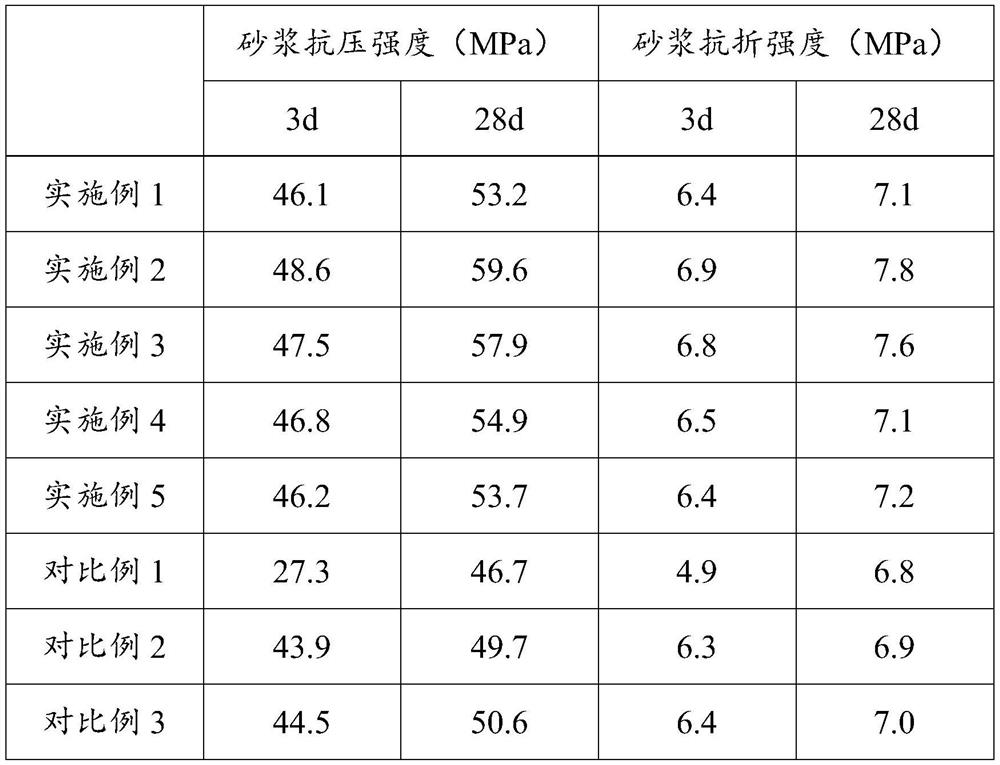

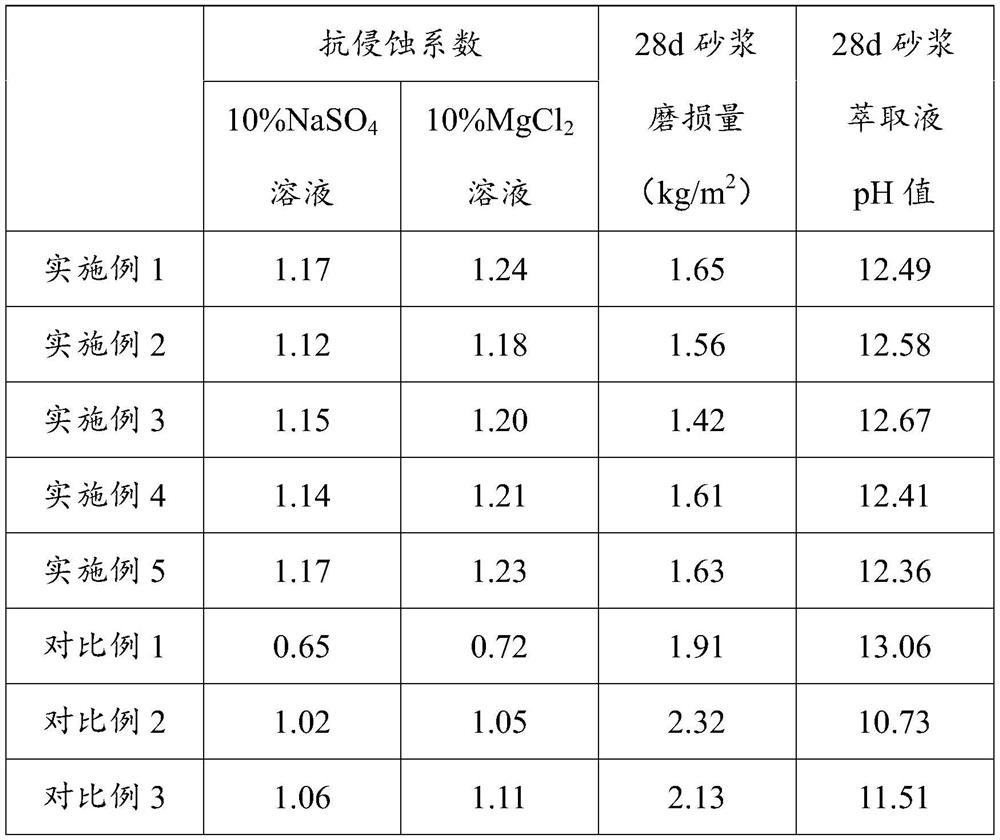

Examples

Embodiment 1

[0047] A solid waste-based high-iron sulfoaluminate marine cementitious material, which is composed of the following raw materials in weight fractions: 80 parts of solid waste-based high-iron sulfoaluminate cement clinker; 5 parts of desulfurized gypsum; 5 parts of limestone tailings; steel slag 10 parts; 0.15 parts of water reducer; 0.05 parts of retarder; 4 parts of silica fume.

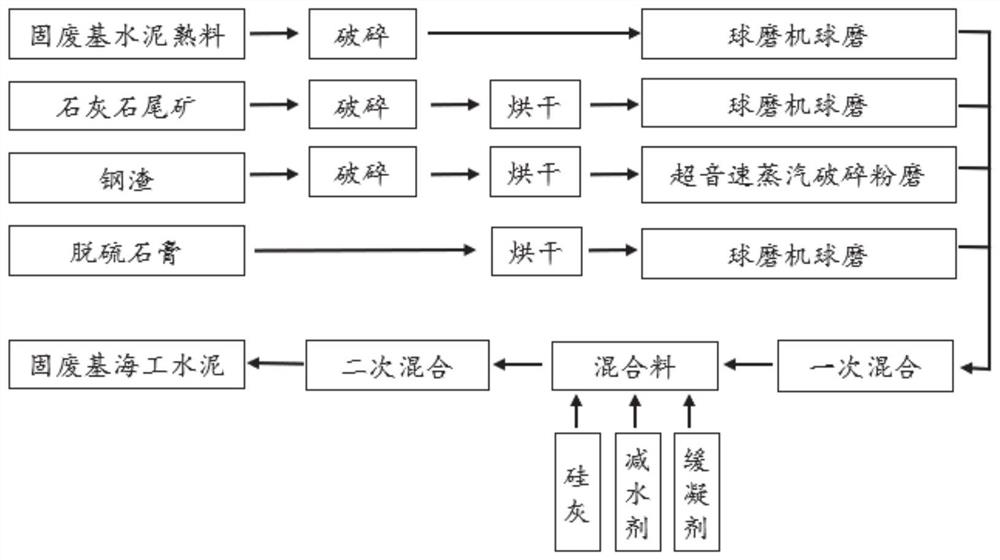

[0048] The preparation method of solid waste-based high-iron sulfoaluminate marine cementitious material is as follows figure 1 As shown, the specific steps are as follows:

[0049] 1. Crush and ball mill the solid waste-based high-iron sulfoaluminate cement clinker until the specific surface area is 300m 2 / Kg, spare.

[0050] After drying the desulfurized gypsum, ball mill until the specific surface area is 300m 2 / Kg, spare.

[0051] Crushing and ball milling the limestone tailings until the specific surface area is 300m 2 / Kg, spare.

[0052] After the steel slag is crushed, supersonic st...

Embodiment 2

[0056] A solid waste-based high-iron sulfoaluminate marine cementitious material, which is composed of the following raw materials in weight fractions: 75 parts of solid waste-based high-iron sulfoaluminate cement clinker; 5 parts of desulfurized gypsum; 5 parts of limestone tailings; steel slag 15 parts; 0.17 parts of water reducer; 0.07 parts of retarder; 3 parts of silica fume.

[0057] The preparation method of solid waste-based high-iron sulfoaluminate marine cementitious material is as follows figure 1 As shown, the specific steps are as follows:

[0058] 1. Crush and ball mill the solid waste-based high-iron sulfoaluminate cement clinker until the specific surface area is 300m 2 / Kg, spare.

[0059] After drying the desulfurized gypsum, ball mill until the specific surface area is 300m 2 / Kg, spare.

[0060] Crushing and ball milling the limestone tailings until the specific surface area is 300m 2 / Kg, spare.

[0061] After the steel slag is crushed, supersonic st...

Embodiment 3

[0065] A solid waste-based high-iron sulfoaluminate marine cementitious material, which is composed of the following raw materials in weight fractions: 70 parts of solid waste-based high-iron sulfoaluminate cement clinker; 5 parts of desulfurized gypsum; 5 parts of limestone tailings; steel slag 20 parts; 0.2 parts of water reducer; 0.1 parts of retarder; 2 parts of silica fume.

[0066] The preparation method of solid waste-based high-iron sulfoaluminate marine cementitious material is as follows figure 1 As shown, the specific steps are as follows:

[0067] 1. Crush and ball mill the solid waste-based high-iron sulfoaluminate cement clinker until the specific surface area is 300m 2 / Kg, spare.

[0068] After drying the desulfurized gypsum, ball mill until the specific surface area is 300m 2 / Kg, spare.

[0069] Crushing and ball milling the limestone tailings until the specific surface area is 300m 2 / Kg, spare.

[0070] After the steel slag is crushed, supersonic stea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com