A resource utilization method of waste incineration fly ash and industrial solid waste

A technology for waste incineration fly ash and industrial solid waste, applied in the direction of cement production, etc., can solve the problems of pollution degree of industrial solid waste recycling, improper treatment of waste incineration fly ash, insufficient utilization, etc., so as to avoid secondary pollution and realize resource utilization. The effect of chemical utilization and promotion of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

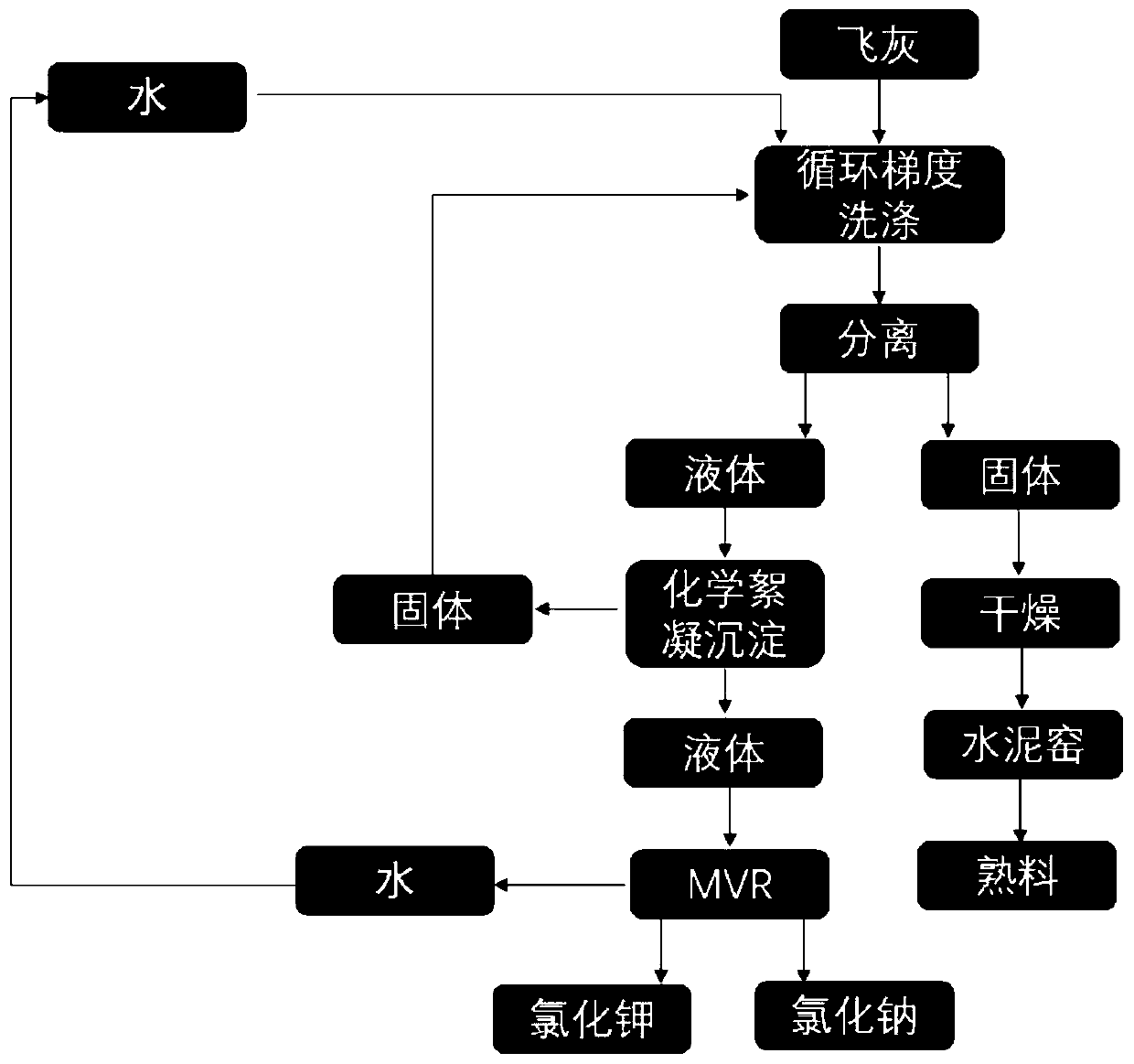

[0068] A method for resource utilization of waste incineration fly ash and industrial solid waste, said method comprising the steps of:

[0069] (1) Extraction of chlorine salts: first mix the waste incineration fly ash with water at a mass ratio of 1:5, then wash with magnetic stirring for 90 minutes, wash with water for 3 times, and filter with 400-mesh nylon filter cloth after washing. Filtrate, add polyaluminum iron silicate to the filtrate at a ratio of 1.5g / L, let it stand for 2 hours for flocculation and precipitation, and obtain supernatant and sediment; take the supernatant and enter the decalcification centrifuge for decalcification, after decalcification The crystal slurry is passed into the MVR evaporator to concentrate to obtain the crystal slurry, which gradually increases the particle size of the crystalline salt through the thickener and then is discharged into the desalination centrifuge for brine separation to obtain chlorine salt; the precipitate after floccu...

Embodiment 2

[0075] A method for resource utilization of waste incineration fly ash and industrial solid waste, said method comprising the steps of:

[0076] (1) Extraction of chlorine salts: first mix the waste incineration fly ash with water at a mass ratio of 1:5, then wash with magnetic stirring for 90 minutes, wash with water for 3 times, and filter with 400-mesh nylon filter cloth after washing. Filtrate, add polyaluminum iron silicate to the filtrate at a ratio of 1.5g / L, let it stand for 2 hours for flocculation and precipitation, and obtain supernatant and sediment; take the supernatant and enter the decalcification centrifuge for decalcification, after decalcification The crystal slurry is passed into the MVR evaporator to concentrate to obtain the crystal slurry, which gradually increases the particle size of the crystalline salt through the thickener and then is discharged into the desalination centrifuge for brine separation to obtain chlorine salt; the precipitate after floccu...

Embodiment 3

[0082] A method for resource utilization of waste incineration fly ash and industrial solid waste, said method comprising the steps of:

[0083] (1) Extraction of chlorine salts: first mix the waste incineration fly ash with water at a mass ratio of 1:5, then wash with magnetic stirring for 90 minutes, wash with water for 3 times, and filter with 400-mesh nylon filter cloth after washing. Filtrate, add polyaluminum iron silicate to the filtrate at a ratio of 1.5g / L, let it stand for 2 hours for flocculation and precipitation, and obtain supernatant and sediment; take the supernatant and enter the decalcification centrifuge for decalcification, after decalcification The crystal slurry is passed into the MVR evaporator to concentrate to obtain the crystal slurry, which gradually increases the particle size of the crystalline salt through the thickener and then is discharged into the desalination centrifuge for brine separation to obtain chlorine salt; the precipitate after floccu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com