Aluminium-based gelling curing agent for curing dehydrated sludge and application thereof

A technology for dewatering sludge and aluminum-based glue, applied in the field of environmental engineering, can solve the problems of serious odor release, solidified sludge is alkaline, and long coagulation time, and achieves reduction of odor gas release, high environmental and economic benefits, and environmental protection. Significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

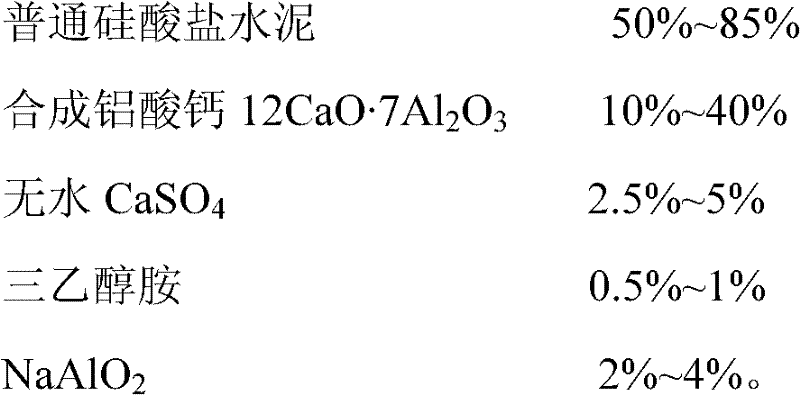

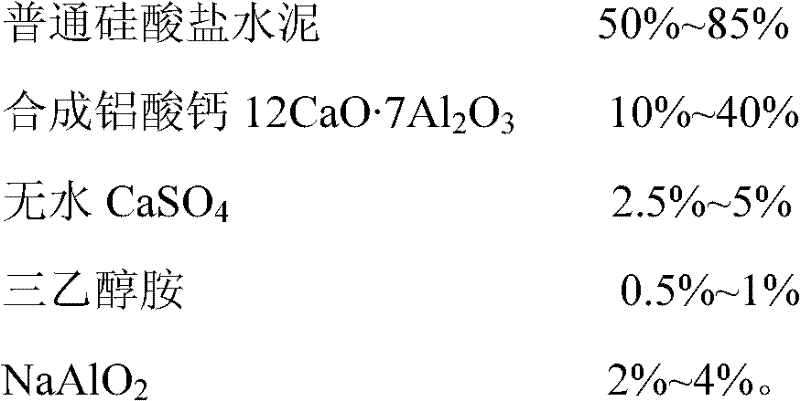

Method used

Image

Examples

Embodiment 1

[0024] First, the synthetic calcium aluminate 12CaO·7Al was prepared by hydrothermal synthesis 2 o 3 , the specific synthesis process is as follows: First, the industrial grade raw material Al(OH) 3 and CaCO 3 Calcined in SX2-10-12 muffle furnace at 900-1000°C for 2-3 hours, cooled to room temperature after calcination, ground, passed through 0.08mm sieve, and the under-sieve was highly active Al 2 o 3 and CaO; then Al 2 o 3 : The molar ratio of CaO=7:12 mixes the two evenly, and mixes evenly with tap water at a mass ratio of water-solid ratio=1~3:1, and the liquid-solid mixture is kept in a hydrothermal reaction kettle at 100±5°C under normal conditions. Hydrothermal synthesis under high pressure conditions for 1-2 hours; finally, after drying the hydrothermal synthesis product, continue calcining in SX2-10-12 muffle furnace at 1000-1200°C for 2-4 hours, and after the heating is completed, it will naturally drop to At room temperature, the clinker formed is synthetic ca...

Embodiment 2

[0028] Synthesis of calcium aluminate 12CaO·7Al by aluminum-based gelling and curing agent of the present invention 2 o 3 The preparation is identical with example 1.

[0029] The components of the aluminum-based gelling curing agent of the present invention are 65% of ordinary Portland cement, calcium aluminate 12CaO·7Al 2 o 3 30%, anhydrous CaSO 4 3%, NaAlO 2 1.5%, triethanolamine is except that the mass ratio of 0.5% is taken, and all the other are identical with example 1. After curing the obtained solidified sludge statically at room temperature for 4 days, the compressive strength of the solidified sludge can reach 60kPa, which meets the requirements for entering the sludge sanitary landfill. After curing for 8-10 days, its compressive strength can reach as high as 0.10MPa.

Embodiment 3

[0031] Synthesis of calcium aluminate 12CaO·7Al as the main component of the aluminum-based gelling and curing agent of the present invention 2 o 3 The preparation is identical with example 1.

[0032] Each component of the aluminum-based gelling curing agent of the present invention is 60% of ordinary Portland cement, calcium aluminate 12CaO·7Al 2 o 3 33%, anhydrous CaSO 4 3.5%, NaAlO 2 2.5%, triethanolamine is except that the mass ratio of 1% is taken, and all the other are identical with example 1. After curing the obtained solidified sludge statically at room temperature for 4-5 days, the compressive strength of the solidified sludge exceeds 50kPa, which meets the requirements for entering the sludge sanitary landfill. After 7-10 days of curing, its compressive strength can reach 0.13MPa. When the time is 28 days, its compressive strength can reach 0.18MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com