A kind of high-strength, quick-setting, expansion multi-purpose grouting material and preparation and application method thereof

A grouting material, high-strength technology, applied in quick-setting, expansive multi-purpose grouting material, high-strength field, can solve the difficulty of increasing the strength in the later stage, the inability to meet the safety production grouting plugging requirements of mines, low expansion rate, etc. Problems, achieve the effect of reducing bleeding and segregation, low price, and improving expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the modified air-entraining agent comprises the following steps:

[0042] C1: fully stir the ordinary metal powder air-entraining agent and the sodium lauryl sulfate surfactant solution according to the mass ratio of 1:1 for 1 hour to obtain a mixed material after mixing it uniformly;

[0043] C2: put the obtained mixed material into a vacuum drying oven for low-temperature drying, the drying temperature is not higher than 30 degrees Celsius, and the drying time is greater than 8 hours;

[0044] C3: Put the dried mixed material into a closed pulverizing sample making machine to fully grind and pulverize to prepare a modified air-entraining agent, and the modified air-entraining agent is 400-1000 mesh.

[0045] Preferably, the double-fast cement adopts 42.5 type, the final setting time is 10min, and the setting time of the grouting material is reduced, and the ordinary Portland cement type is 425# or 525#.

[0046] Preferably, the water-retaini...

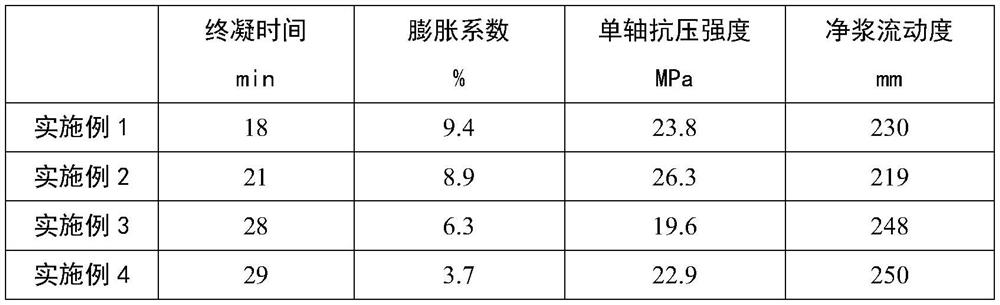

Embodiment 1

[0054] A high-strength, quick-setting, expansive multi-purpose grouting material is configured, including the following components: double-fast cement: 60%; ordinary Portland cement: 30%; water-retaining agent: 0.1%; water-reducing agent: 0.15% ; Modified air-entraining agent: 0.15%; Composite dispersant: 0.05%; Industrial cellulose: 0.05%; Quick lime: 4.5%; Bentonite: 5%.

[0055] Preparation method and application: the above-mentioned raw materials and water are uniformly mixed in a ratio of 0.7:1 by weight, and the obtained slurry is used for grouting and plugging of gas and carbon monoxide toxic and harmful gases gushing out of cracks.

Embodiment 2

[0057] Configure a high-strength, quick-setting, expansive multi-purpose grouting material, including the following components: double-fast cement: 55%; ordinary Portland cement: 45%; water retention agent: 0.1%; water reducer: 0.15% ; Modified air-entraining agent: 0.1%; Composite dispersant: 0.05%; Industrial cellulose: 0.1%; Quick lime: 5%; Bentonite: 4.5%.

[0058] Preparation method and application: the above-mentioned raw materials and water are uniformly mixed in a weight ratio of 0.8:1, and the obtained slurry is used for efficient sealing of gas drainage holes and gas pressure measurement holes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solidification time | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com