Sealing grouting material and its preparation method and application

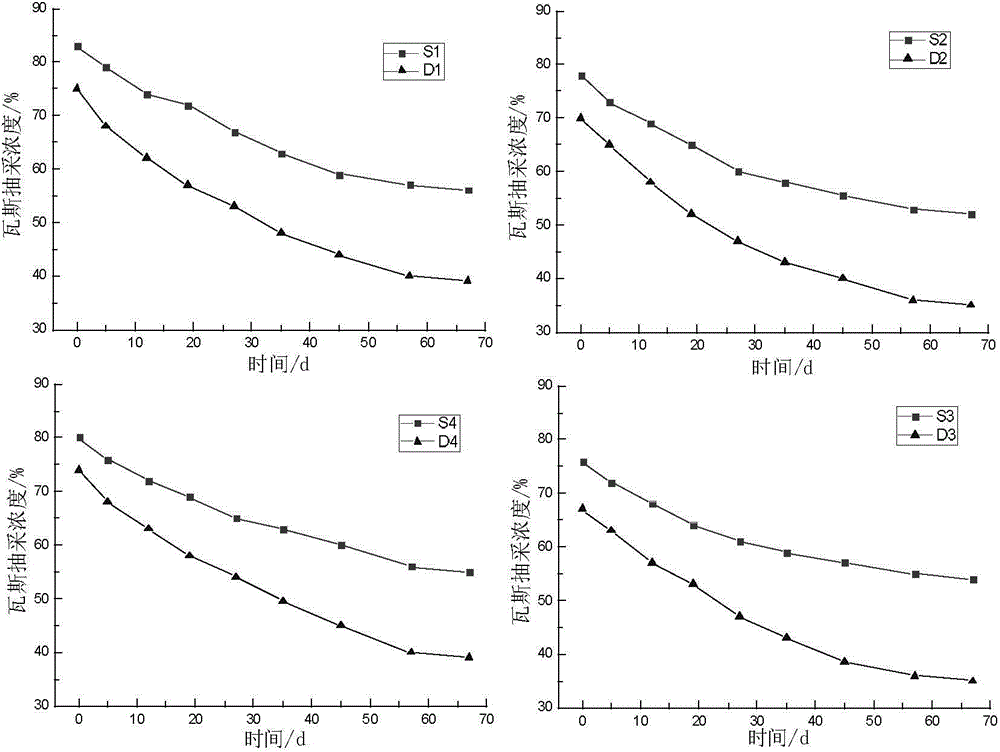

A grouting material and hole sealing technology, which is applied in the field of grouting materials for sealing holes, can solve the problems of high viscosity of mixed grout, difficulty in grouting, and low compressive strength, so as to improve the concentration of gas drainage and solidification High strength, non-toxic and harmless price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

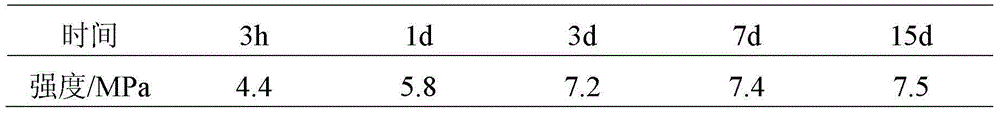

Examples

Embodiment 1

[0026] The parts by weight of each raw material are as follows:

[0027] 60 parts by weight of sulfoaluminate cement, α-CaSO 4 0.5H 2 45 parts by weight of O (or high-strength gypsum), 20 parts by weight of quicklime, 3 parts by weight of potassium aluminum sulfate dodecahydrate, 3 parts by weight of sodium bicarbonate, 0.3 parts by weight of citric acid, 0.2 parts by weight of sodium lauryl sulfate, aluminum powder 0.1 parts by weight;

[0028] First, add high-strength gypsum, potassium aluminum sulfate dodecahydrate, sodium bicarbonate, citric acid, sodium lauryl sulfate, and aluminum powder into the mixer according to the required weight parts for preliminary mixing, and finally add sulfoaluminic acid according to the required weight parts Salt cement and quicklime are mixed evenly to obtain the two-stage expansion composite sealing grouting material provided by the invention, which can be stored in a sealed bag in a dry place.

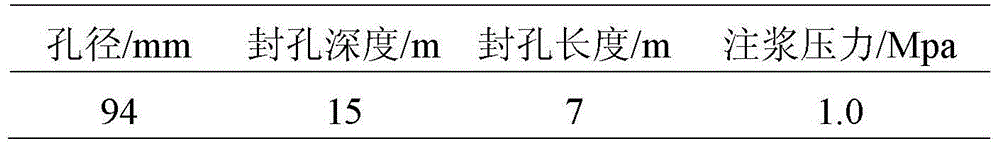

[0029] During underground hole sealing co...

Embodiment 2

[0031] The parts by weight of each raw material are as follows:

[0032] 63 parts by weight of sulfoaluminate cement, α-CaSO 4 0.5H 2 48 parts by weight of O (or high-strength gypsum), 22 parts by weight of quicklime, 4 parts by weight of potassium aluminum sulfate dodecahydrate, 4 parts by weight of sodium bicarbonate, 0.4 parts by weight of citric acid, 0.3 parts by weight of sodium lauryl sulfate, aluminum powder 0.12 parts by weight;

[0033] First, add high-strength gypsum, potassium aluminum sulfate dodecahydrate, sodium bicarbonate, citric acid, sodium lauryl sulfate, and aluminum powder into the mixer according to the required weight parts for preliminary mixing, and finally add sulfoaluminic acid according to the required weight parts Salt cement and quicklime are mixed evenly to obtain the two-stage expansion composite sealing grouting material provided by the invention, which can be stored in a sealed bag in a dry place.

[0034] During underground hole sealing c...

Embodiment 3

[0036] The parts by weight of each raw material are as follows:

[0037] 65 parts by weight of sulfoaluminate cement, α-CaSO 4 0.5H 2 50 parts by weight of O (or high-strength gypsum), 25 parts by weight of quicklime, 5 parts by weight of potassium aluminum sulfate dodecahydrate, 5 parts by weight of sodium bicarbonate, 0.5 parts by weight of citric acid, 0.4 parts by weight of sodium lauryl sulfate, aluminum powder 0.15 parts by weight;

[0038] First, add high-strength gypsum, potassium aluminum sulfate dodecahydrate, sodium bicarbonate, citric acid, sodium lauryl sulfate, and aluminum powder into the mixer according to the required weight parts for preliminary mixing, and finally add sulfoaluminic acid according to the required weight parts Salt cement and quicklime are mixed evenly to obtain the two-stage expansion composite sealing grouting material provided by the invention, which can be stored in a sealed bag in a dry place.

[0039]During underground hole sealing co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com