Early strength type polycarboxylate superplasticizer and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of concrete admixtures to achieve the effects of shortening the initial setting time and final setting time, improving the early strength performance and improving the durability performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

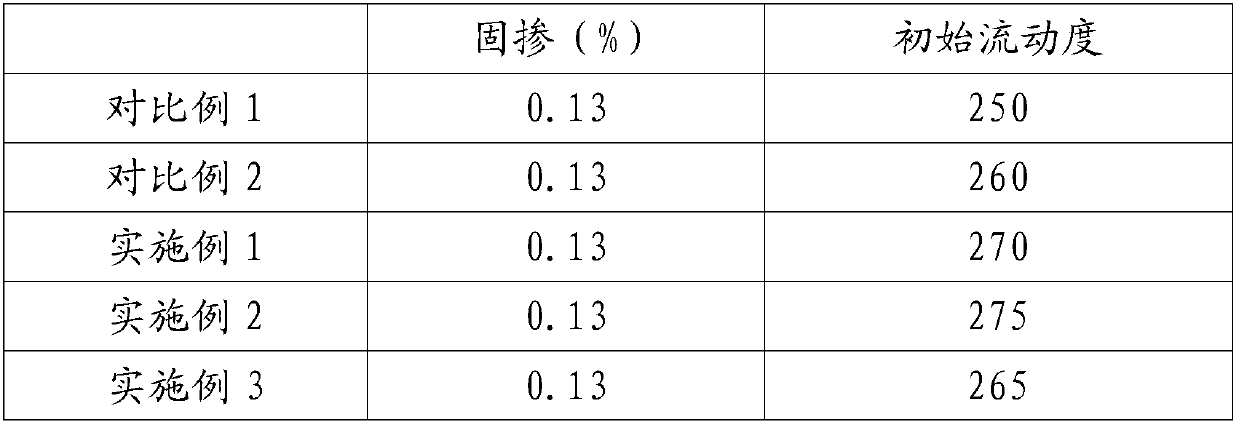

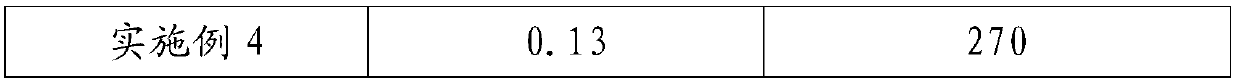

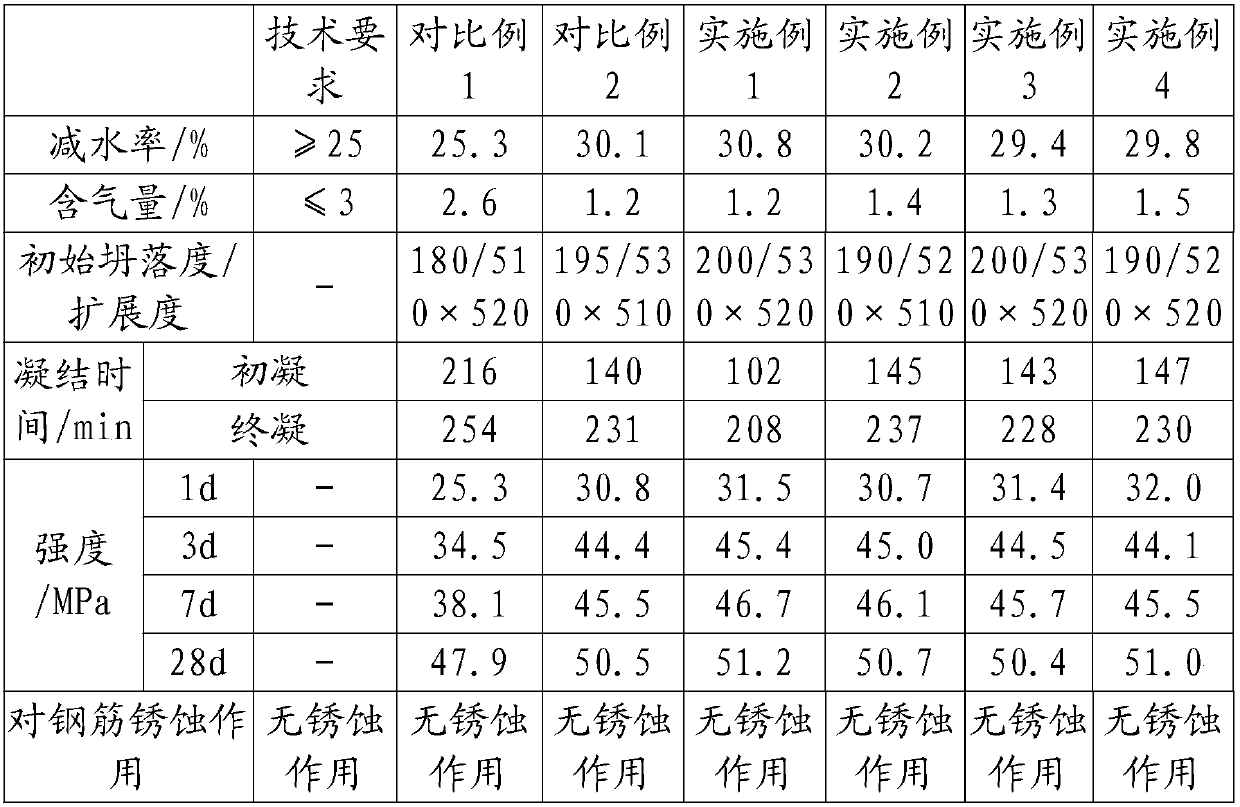

Examples

preparation example Construction

[0026] In the embodiment of the present invention, the preparation method of early-strength polycarboxylate water reducer can specifically include:

[0027] Put 80 parts of deionized water, block unsaturated polyoxyethylene ether, and oxidative initiator into the reactor, stir and dissolve evenly, and heat to 30-60°C; dissolve acrylic acid and functional monomers in 40 parts of deionized water Prepare dropwise liquid material A for later use, dissolve the chain transfer agent and reducing initiator in 40 parts of deionized water to prepare dropwise liquid material B for later use; at the same time, add the prepared material A and B into the reaction kettle dropwise at a uniform speed Material, material A is added dropwise for 3-4 hours, material B is added dropwise for 3.5-5 hours, and the heat preservation reaction is 1-2 hours; add neutralizer to adjust the pH to 6-7, and add the remaining deionized water to a solid content of 40 -50%, to obtain early-strength polycarboxylat...

Embodiment 1

[0035] An early-strength polycarboxylate water reducer, the raw materials are calculated in parts by weight. Put 80 parts of deionized water, 116 parts of block unsaturated polyoxyethylene ether with a molecular weight of 5000, and 0.2 parts of hydrogen peroxide into the reaction kettle, stir and dissolve evenly, and heat to 30-60°C. Dissolve 13 parts of acrylic acid and 1.2 parts of 2-acrylamido-2-methylpropenesulfonic acid in 40 parts of deionized water to prepare dropwise liquid A for later use. Dissolve 0.55 parts of thioglycolic acid and 0.16 parts of vitamin C in 40 parts The deionized water is prepared as the dripping solution B material for later use. At the same time, add the prepared material A and material B dropwise to the reactor at a constant speed, add material A dropwise for 3 hours, add material B dropwise for 3.5 hours, and keep warm for 1 hour. Add 3 parts of 30% sodium hydroxide solution to adjust the pH to 6-7, add 32 parts of deionized water until the so...

Embodiment 2

[0037] An early-strength polycarboxylate water reducer, the raw materials are calculated in parts by weight. Put 80 parts of deionized water, 116 parts of block unsaturated polyoxyethylene ether with a molecular weight of 5000, and 0.2 parts of ammonium persulfate into the reaction kettle, stir and dissolve evenly, and heat to 40°C. Dissolve 13 parts of acrylic acid, 0.4 parts of sodium methallyl sulfonate, and 0.8 parts of acrylamide in 40 parts of deionized water to prepare dropwise liquid A for later use. Dissolve 0.55 parts of mercaptopropionic acid and 0.16 parts of vitamin C in 40 parts One part deionized water is prepared as dropwise liquid B material for subsequent use. At the same time, add the prepared material A and material B dropwise to the reactor at a constant speed, add material A dropwise for 3 hours, add material B dropwise for 3.5 hours, and keep warm for 1 hour. Add 3.2 parts of 30% sodium hydroxide solution to adjust the pH to 6-7, add 33 parts of deioniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com