A high-efficiency permeable reinforced concrete preservative

A reinforced concrete and permeable technology, applied in the field of concrete admixtures, can solve problems such as poor anticorrosion effect, prone to aging, and coating failure, so as to improve the ability of structural damage and impermeability, improve flow dispersion, Effect of inhibiting steel corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

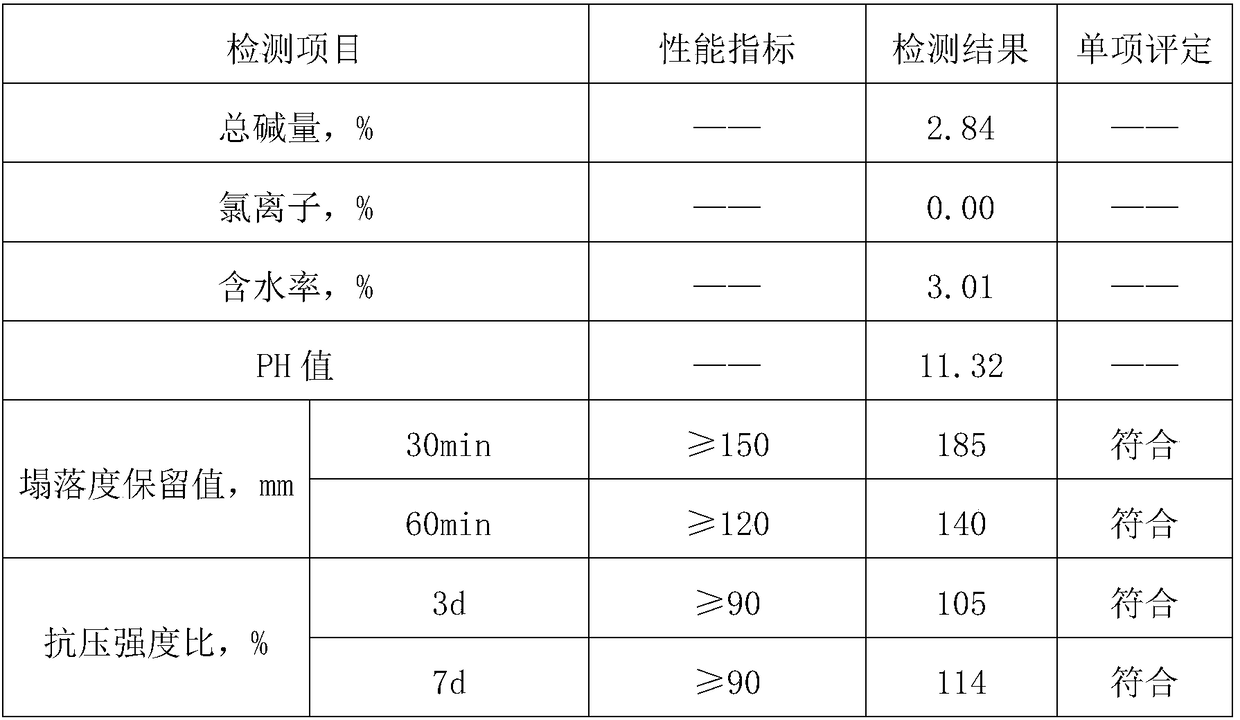

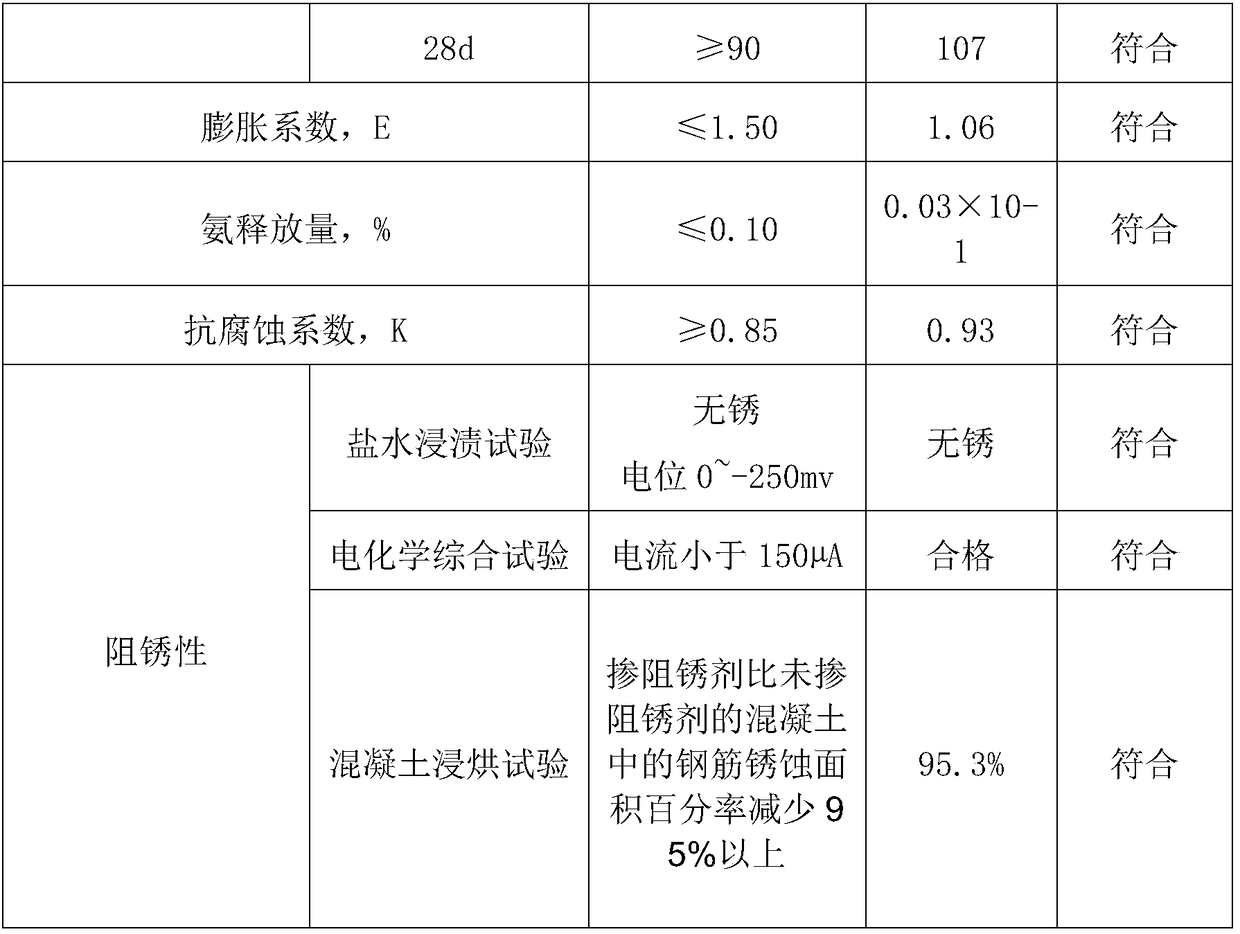

Image

Examples

Embodiment 1

[0024] A high-efficiency penetrating reinforced concrete antiseptic, said antiseptic includes antiseptic component, anti-rust component, high molecular polymer component, wherein, in terms of mass percentage, anti-corrosion component 50%, anti-rust component 30 %, the polymer component is 20%, and the total mass percentage of each component is 100%;

[0025] Among the anti-corrosion components, SiO 2 95%, Al 2 O 3 0.9%, Fe 2 O 3 0.8%, MgO0.7%, CaO 0.8%, NaO 1.8%, and the PH of the anticorrosive component is 7.21.

[0026] The composition of the raw material components of the anti-rust group and their weight percentages are as follows: 62% bisimidazoline quaternary ammonium salt, 32% didecyldimethylammonium carbonate, and 6% sodium molybdate.

[0027] The composition of the high molecular polymer component by weight percentage is as follows: polytrifluorochloroethylene 40%, pure acrylic nanoemulsion 30%, and polysiloxane 30%.

[0028] The application of the above-mentioned high-effi...

Embodiment 2

[0034] A high-efficiency permeable reinforced concrete antiseptic. The antiseptic includes an antiseptic component, a rust-inhibiting component, and a high molecular polymer component. The anti-corrosion component is 60% and the rust-inhibiting component 25 %, high molecular polymer component 15%, the total mass percentage of each component is 100%;

[0035] Among the anti-corrosion components, SiO 2 92%, Al 2 O 3 1.5%, Fe 2 O 3 2.2%, MgO1.6%, CaO1.0%, NaO 1.7%, PH of anticorrosive component is 7.21.

[0036] The composition of the raw material components of the anti-rust group and their weight percentages are as follows: bisimidazoline quaternary ammonium salt 68%, didecyldimethylammonium carbonate 25%, and sodium molybdate 7%.

[0037] The composition of the high molecular polymer component by weight percentage is as follows: polytrifluorochloroethylene 55%, modified acrylic nanoemulsion 35%, and polysiloxane 10%.

[0038] The application of high-efficiency permeable reinforced c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com