Foam cement filling type concrete composition heat preservation building block and manufacturing method thereof

A foamed cement, composite thermal insulation technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of poor dimensional stability, poor water resistance, and high cost of thermal insulation materials, and achieve good dimensional stability, durability, and production. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

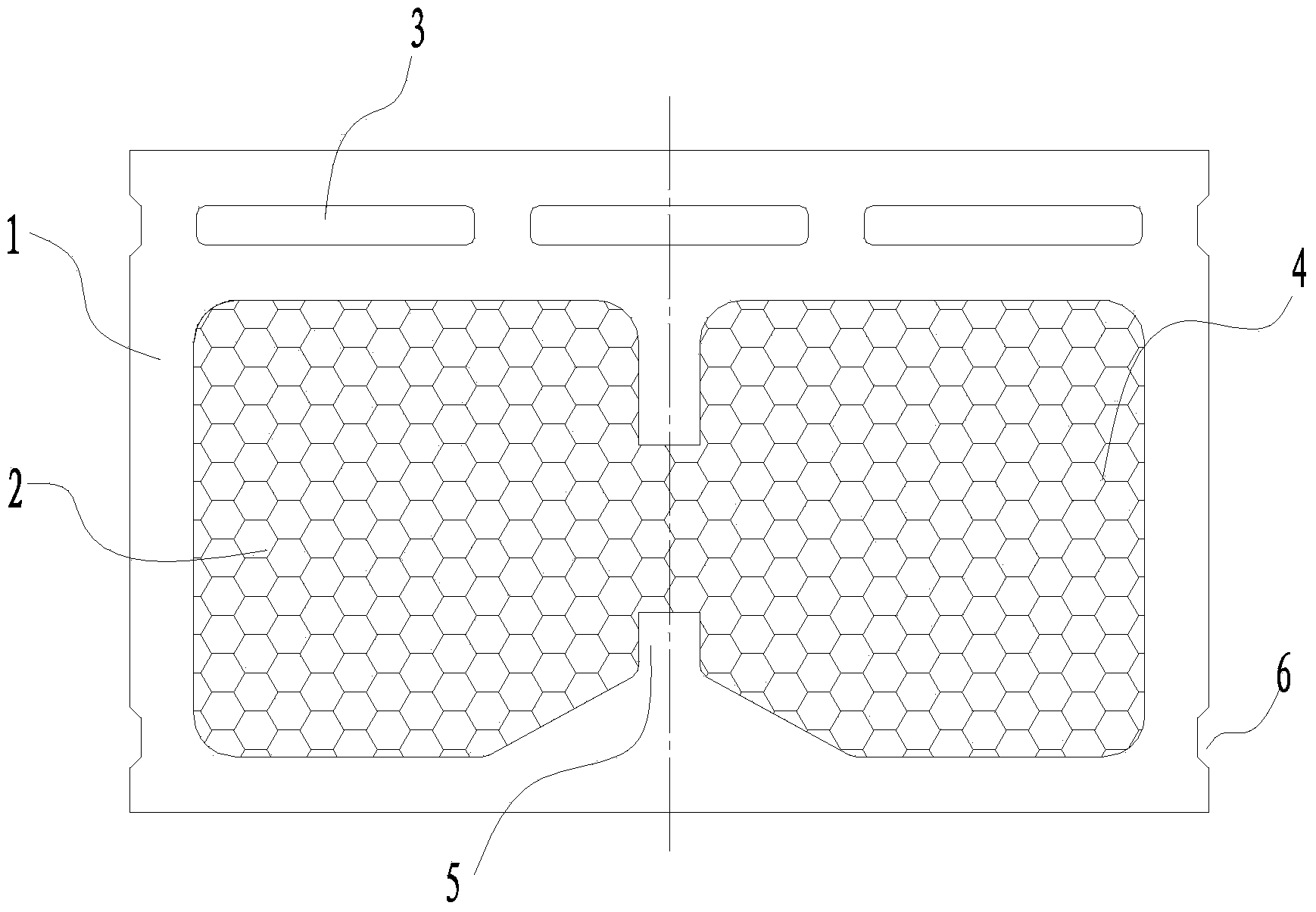

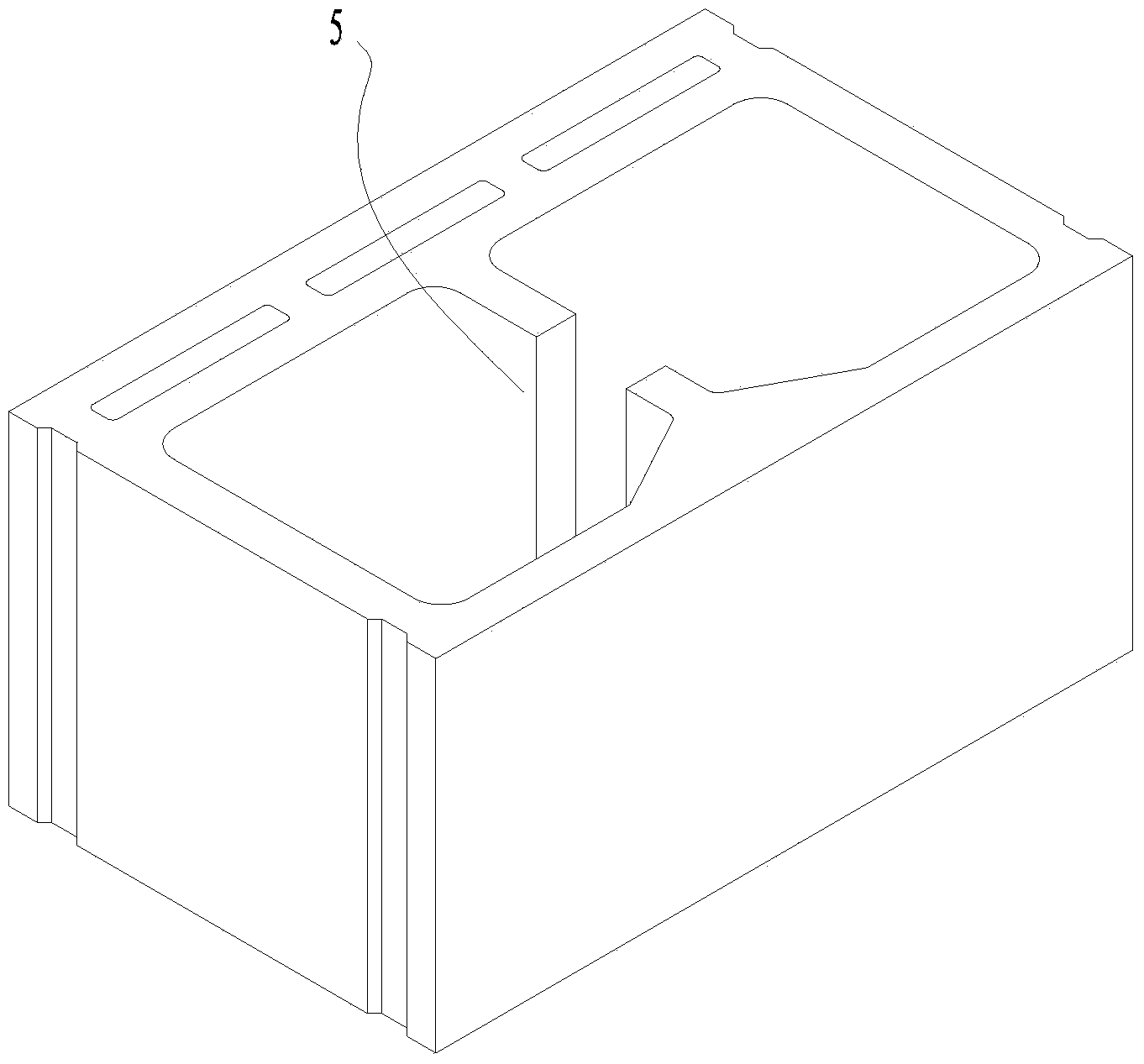

[0099] The size of the concrete matrix with cavity is 390mm×240mm×190mm, the shape is cuboid, the side is flat, and there is a row of air interlayers with a width of 20mm in the inner matrix of the rear end surface, and a row of large-area cavities inside. . The air interlayer is composed of 3 small holes, the shape of the cavity is the upper and lower through holes, and there is a convex rib in the middle, and the convex rib is provided with a raised broken mark. The foamed cement filling body is filled in the cavity of the concrete matrix through the online filling equipment. The concrete matrix with a cavity and the filled foam cement are combined into one body through cementation and mechanical occlusal (that is, the embedded structure formed with the fracture).

[0100] Use a forced concrete mixer to mix cement, ultra-light ceramsite, fly ash, admixtures and water to form a mixture, and use a block forming machine to form a concrete matrix with a cavity. After 2 hours o...

Embodiment 2

[0104] The size of the concrete matrix with cavity is 390mm×240mm×190mm. large cavity. The air interlayer is composed of 2 small holes, the shape of the cavity is upper and lower through holes, and there are 3 convex ribs in the middle. The foamed cement filling body is filled in the cavity of the concrete matrix through off-line filling. The concrete matrix with the cavity and the filled foamed cement are combined into one body through bonding.

[0105] Use a forced concrete mixer to mix cement, recycled materials from construction waste, fly ash, concrete admixtures and water to form a mixture, and use a block forming machine to form a concrete matrix with a cavity. The green body with a supporting plate is 50 ℃ steam curing for 4 hours before use. Mix and stir cement, silica fume, modifier, aluminum powder and water evenly to make foamed cement slurry for filling, and then fill it in the cavity of the concrete matrix online. After the chemical foaming of the foamed cemen...

Embodiment 3

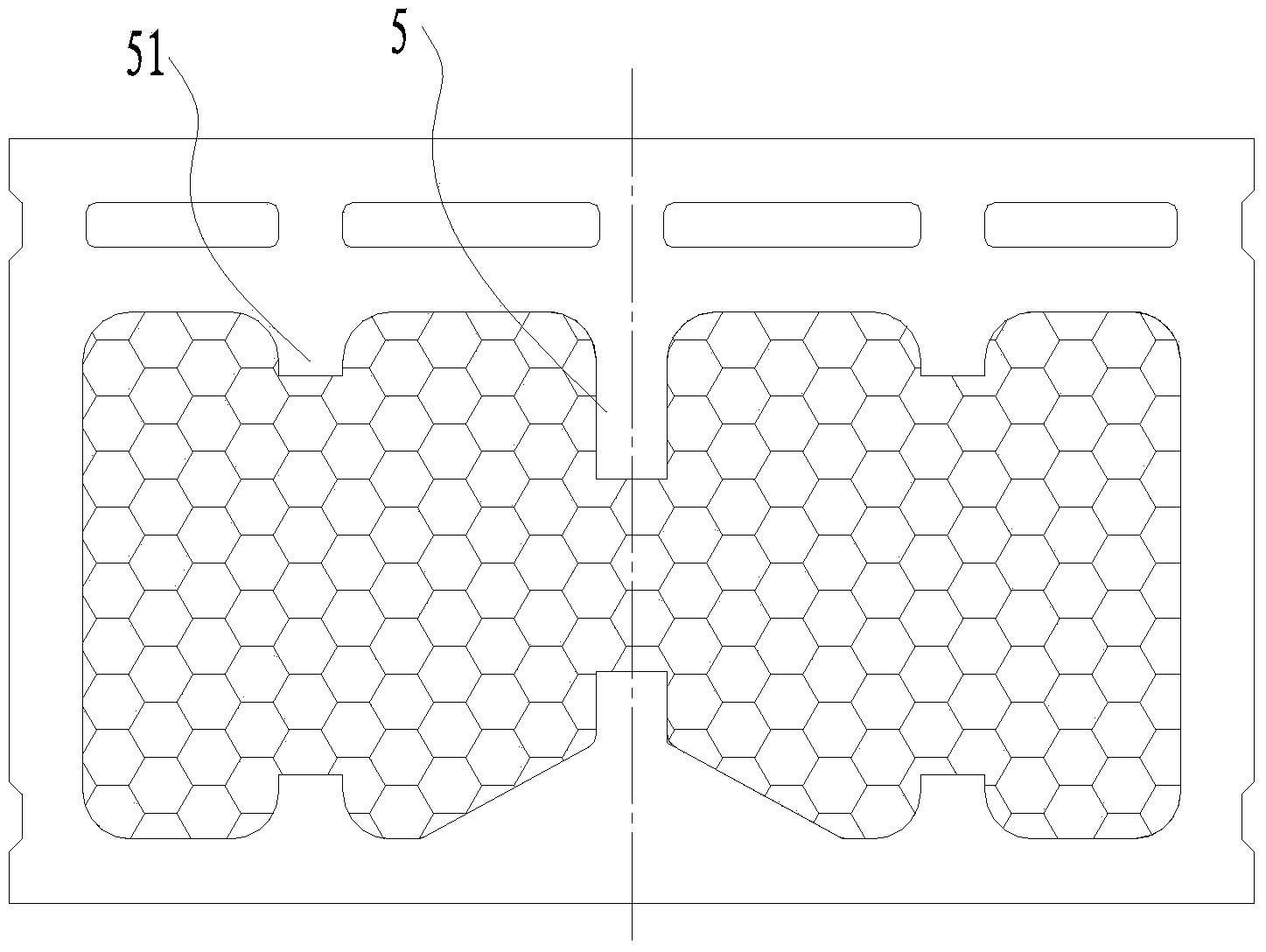

[0108] The size of the concrete matrix with a cavity is 390mm×310mm×190mm, and the shape is a cuboid. A pair of ash grooves are respectively provided on the two sides and the front and rear end surfaces. There is a row of cavities with a larger width. The air interlayer is composed of 4 small holes, the shape of the cavity is a groove structure (that is, has a groove bottom 41), and there are 3 pairs of convex ribs in the middle, and each convex rib is provided with a concave fracture. The foamed cement filling body is filled in the cavity of the concrete matrix through the line. The concrete matrix with the cavity and the filled foamed cement are combined into one body through cementation and mechanical occlusal. The cement, industrial tailings recycled raw materials, fly ash, concrete admixture and water are stirred and mixed evenly by a forced concrete mixer. Materials, using a block forming machine to form a concrete matrix with a cavity, the body with a supporting plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Dry apparent density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com