Luminous PET-brick powder building block

A PET-, light-emitting technology, applied in the field of decorative building materials, to achieve the effects of energy saving, good mechanical properties, and high impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Table 1 Mixing gradation of brick powder.

[0028]

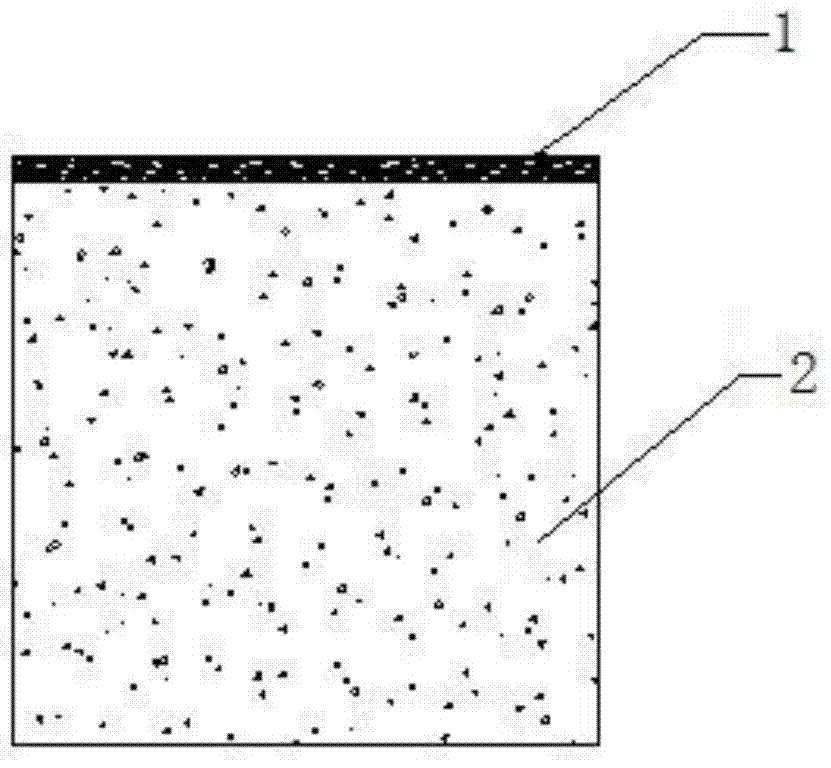

[0029] Such as figure 1 As shown, the luminous layer is composed of PET and luminous powder. During the production process, the mass ratio of phosphor to PET is 1:2. PET material is melted first, and after it becomes liquid, phosphor is applied and stirred evenly with PET for later use. In the production process of the functional layer, mix and grade PET, fly ash and brick powder as shown in Table 1 according to the mass ratio of coal ash, PET and brick powder as 1:9:20, and heat and melt at 300°C after mixing evenly. The heating time is 2h. During the heating process, ventilation should be maintained and the test mold should be heated at the same time as the above-mentioned mixture. After the PET is completely melted, stir evenly, quickly pour it into the heating test mold, vibrate, compact, and level off. The mixture of liquid PET and luminous powder is filled and filled, placed in an oven, adjusted to 200°C, c...

Embodiment 2

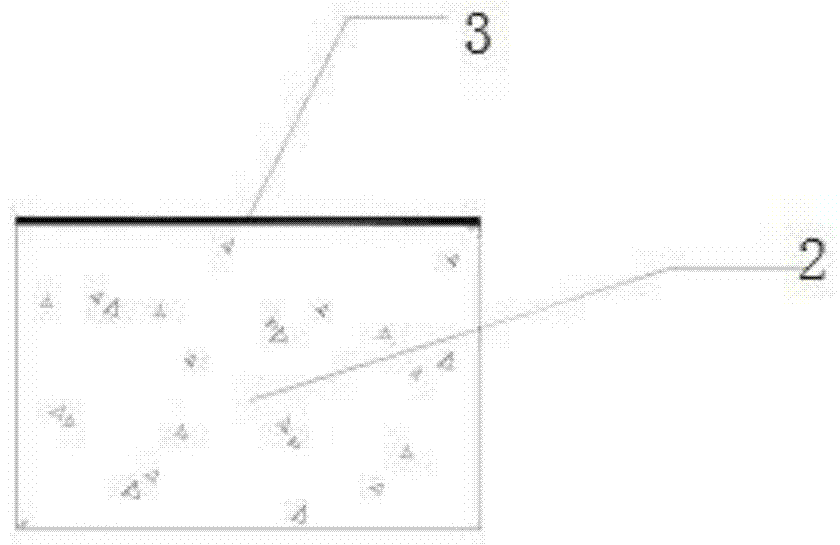

[0031] Make molds according to the size of the luminous square bricks such as figure 2 , the mold is a cuboid with five sides closed and one side with an opening for filling the mixture. In the manufacturing process, a movable steel plate 3 is left on the upper part, which can be drawn out and has a thickness of 2 mm. First, the functional layer 2 is as shown in Table 1. The brick powder mixing gradation shown is based on the mixture of fly ash, PET and brick powder with a mass ratio of 1:9:20. After mixing evenly, heat and melt at 300°C for 2 hours. The mixture of light-emitting layer 1 is heated and melted according to the mass ratio of phosphor powder and PET of 1:2. Put the functional layer mixture into the mold for extrusion molding, and then image 3 Pull out the movable steel plate 3, pour the light-emitting layer mixture, and extrude again. During the two extrusions and filling the mixture, the temperature of the mold should be above 200°C. After the second extrusion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com