Alkaline magnesium oxysulfate cement and preparation method thereof

A magnesium oxysulfide cement and alkaline technology, which is applied in the field of cement, can solve the problems of poor mechanical strength and water resistance of magnesium oxysulfide cement, and achieve the effects of enhanced mechanical properties, simple preparation method, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Example 1 Preparation of Alkaline Magnesium Oxide Cement by Desulfurization By-products of Magnesium Process and Fly Ash of Coal-fired Units

[0076] Among them, magnesium oxide is light-burned magnesium oxide powder obtained by calcination of magnesite, with a fineness of 200 mesh; sulfuric acid heptahydrate solution is prepared from magnesium sulfate heptahydrate prepared by magnesium desulfurization recovery; fly ash is North United Electric Power Dala Fly ash provided by the special power plant;

[0077] Alkaline magnesium oxysulfate cement is prepared through the following steps:

[0078] (1) Magnesium sulfate heptahydrate is dissolved in water and configured into a mass fraction of 12% magnesium sulfate heptahydrate solution;

[0079] (2) Take the above-mentioned raw materials by proportioning: 100 parts of magnesium oxide, 200 parts of 12% magnesium sulfate heptahydrate solution, 300 parts of fly ash, 0.1 part of boric acid, 0.5 part of lactic acid;

[0080] (3...

Embodiment 2

[0083] Example 2 Preparation of Alkaline Magnesium Oxygen Sulfate Cement by Using Desulfurization By-products of Magnesium Process and Fly Ash of Coal-fired Units

[0084] Alkaline magnesium oxysulfate cement is prepared through the following steps:

[0085] (1) Magnesium sulfate heptahydrate is dissolved in water and configured into a mass fraction of 20% magnesium sulfate heptahydrate solution;

[0086] (2) Take raw materials by weight ratio: 100 parts of magnesium oxide, 150 parts of 20% magnesium sulfate heptahydrate solution, 200 parts of fly ash, 0.2 part of boric acid, 1.0 part of lactic acid;

[0087] (3) adding boric acid in magnesium sulfate heptahydrate solution;

[0088] (4) Add lactic acid and fly ash respectively in the magnesium oxide powder, drop in the blender, step (3) gained magnesium sulfate solution is added in the blender, stir rapidly and evenly form cement slurry;

[0089] (5) Cast the obtained cement paste into a steel test mold, remove the mold afte...

Embodiment 3

[0090] Example 3 Preparation of Alkaline Magnesium Oxide Cement by Magnesium Desulfurization By-products and Fly Ash of Coal-fired Units

[0091] Alkaline magnesium oxysulfate cement is prepared through the following steps:

[0092] (1) Magnesium sulfate heptahydrate is dissolved in water and configured into a mass fraction of 24% magnesium sulfate heptahydrate solution;

[0093] (2) Take above-mentioned raw material by proportioning: 100 parts of magnesium oxide, 100 parts of 24% magnesium sulfate heptahydrate solution, 100 parts of fly ash, 0.1 part of boric acid, 0.5 part of lactic acid;

[0094] (3) adding boric acid in the magnesium sulfate solution;

[0095] (4) Add lactic acid and fly ash successively in the magnesium oxide powder, drop in the blender, step (3) gained magnesium sulfate heptahydrate solution is added in the blender, stir rapidly and evenly form cement slurry;

[0096] (5) Cast the obtained cement paste into a steel test mold, remove the mold after curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

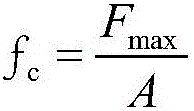

| compressive strength | aaaaa | aaaaa |

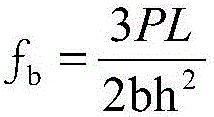

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com