A kind of magnesium oxysulfate cement lightweight foam brick and preparation method thereof

A technology of magnesium oxysulfide cement and foamed bricks, which is applied in ceramic products, other household appliances, household appliances, etc., to achieve the effects of excellent bending resistance, reduced water absorption rate, and strong water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of embodiment 1 magnesium oxysulfate cement lightweight foam brick

[0040] 1) dissolving magnesium sulfate with water, and configuring it into a magnesium sulfate solution with a concentration of 20%, for subsequent use;

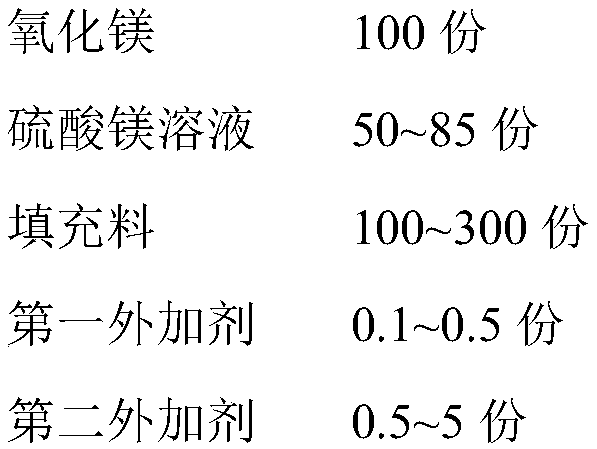

[0041] 2) take each raw material by formula;

[0042]

[0043] 3) adding the organosilicon water repellent and sodium tetraborate into the magnesium sulfate solution, and fully stirring to obtain a mixed solution;

[0044] 4) Add sodium tartrate and fillers to magnesium oxide in turn, mix well, add the mixed solution in step 3), and continue to stir until well mixed;

[0045] 5) drop into medium-alkali glass fiber and aluminum hydroxide successively in the mixture obtained in step 4) while stirring, and stir evenly;

[0046] 6) When the temperature of the mixture is reduced to 55°C-65°C, add ammonium bicarbonate to the mixture obtained in step 5) and stir to form a foaming slurry;

[0047] 7) Pour the stirred foam slurry ...

Embodiment 2

[0048] The preparation method of embodiment 2 magnesium oxysulfate cement lightweight foam brick

[0049] 1) dissolving magnesium sulfate with water, and configuring it into a magnesium sulfate solution with a concentration of 20%, for subsequent use;

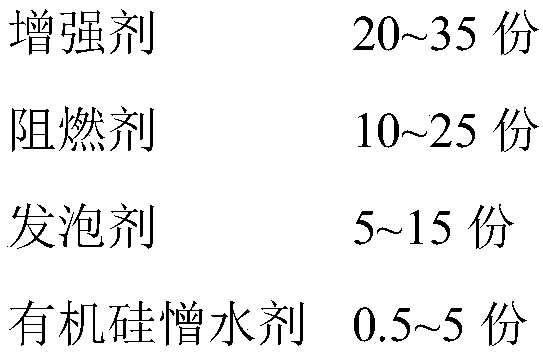

[0050] 2) take each raw material by formula;

[0051]

[0052] 3) adding the organosilicon water repellent and sodium tetraborate into the magnesium sulfate solution, and fully stirring to obtain a mixed solution;

[0053] 4) Add sodium tartrate and fillers to magnesium oxide in turn, mix well, add the mixed solution in step 3), and continue to stir until well mixed;

[0054] 5) drop into medium-alkali glass fiber and aluminum hydroxide successively in the mixture obtained in step 4) while stirring, and stir evenly;

[0055] 6) When the temperature of the mixture is reduced to 55°C-65°C, add ammonium bicarbonate to the mixture obtained in step 5) and stir to form a foaming slurry;

[0056] 7) Pour the stirred foam slurry ...

Embodiment 3

[0057] The preparation method of embodiment 3 magnesium oxysulfide cement lightweight foam brick

[0058] 1) dissolving magnesium sulfate with water, and configuring it into a magnesium sulfate solution with a concentration of 20%, for subsequent use;

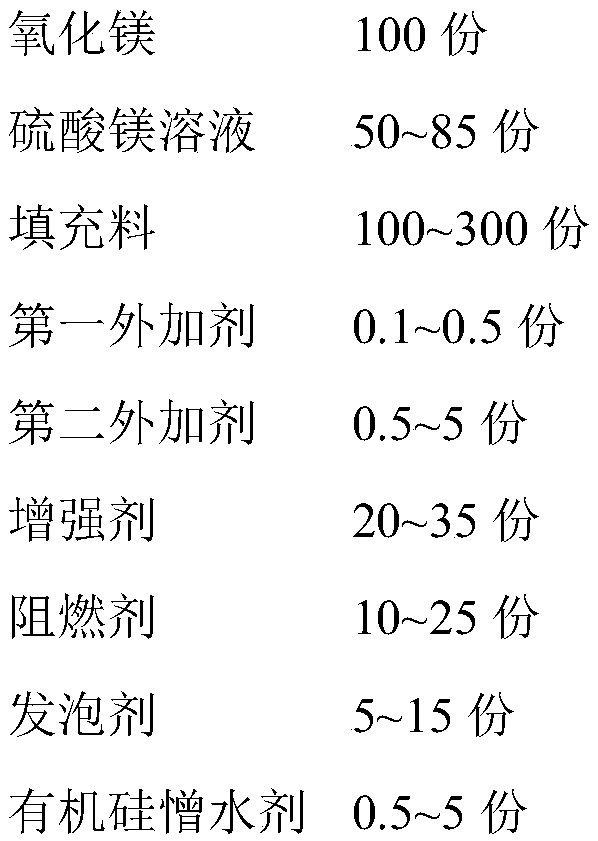

[0059] 2) take each raw material by formula;

[0060]

[0061]

[0062] 3) adding the organosilicon water repellent and sodium tetraborate into the magnesium sulfate solution, and fully stirring to obtain a mixed solution;

[0063] 4) Add sodium tartrate and fillers to magnesium oxide in turn, mix well, add the mixed solution in step 3), and continue to stir until well mixed;

[0064]5) drop into medium-alkali glass fiber and aluminum hydroxide successively in the mixture obtained in step 4) while stirring, and stir evenly;

[0065] 6) When the temperature of the mixture is reduced to 55°C-65°C, add ammonium bicarbonate to the mixture obtained in step 5) and stir to form a foaming slurry;

[0066] 7) Pour the stirred f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com