Efficient expansion clinker for cement concrete, preparation method of efficient expansion clinker and application of efficient expansion clinker

A kind of technology of cement concrete and expanded clinker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of a kind of high-efficiency expansion clinker for cement concrete

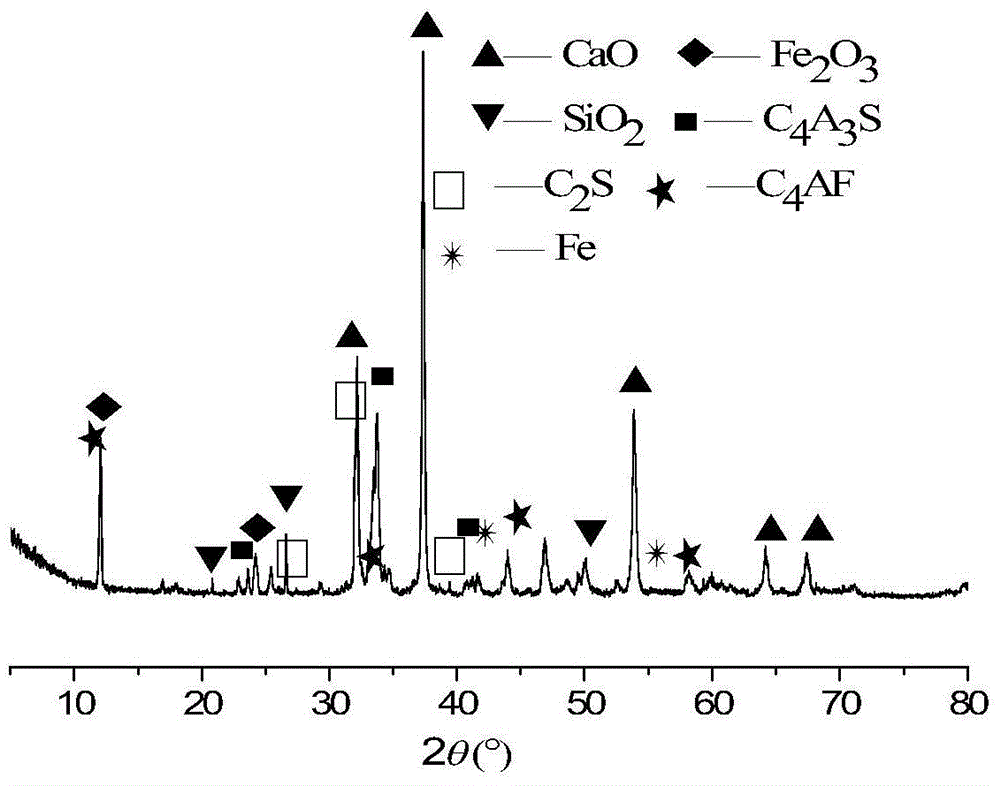

[0044] According to the raw material composition and mass fraction of 22% pyrite slag, 8% rice husk ash and 70% limestone, each component is taken, and after crushing and mixing, it is jointly ground by a mill to a fineness of 250m 2 / kg of raw meal powder. The ground raw meal powder was calcined at 1300°C, and calcined at this temperature for 60 minutes. After the calcination, the fired sample was immediately taken out and quenched in the air, and the specific surface area was 300m2 after grinding. 2 / kg of expanded clinker powder for cement concrete.

[0045] Table 1 is the chemical composition (wt.%) of raw material limestone, pyrite slag and rice husk ash

[0046] name

CaO

Fe 2 o 3

Al 2 o 3

SiO 2

SO 3

MgO

C

loss

limestone

54.07

1.72

0.58

0.25

-

0.18

-

43.2

pyrite cinder

6.17

...

Embodiment 2

[0058] (1) Preparation of high-efficiency expansion clinker and expansion agent for cement concrete

[0059] Limestone, pyrite slag and rice husk ash with a mass ratio of 60:30:10 are crushed and mixed, and are jointly ground by a mill to a fineness of 150m 2 / kg of raw meal powder. The ground raw meal powder was calcined at 1200°C for 120 minutes at this temperature, and the calcined sample was taken out immediately after the calcination and quenched in the air, and the specific surface area was 400m2 after grinding. 2 / kg of expanded clinker powder for cement concrete.

[0060] Table 3 is the chemical composition (wt.%) of raw material limestone, pyrite slag and rice husk ash

[0061] name

CaO

Fe 2 o 3

al 2 o 3

SiO 2

SO 3

MgO

C

loss

limestone

54.07

1.72

0.58

0.25

-

0.18

-

43.2

pyrite cinder

6.17

44.80

26.86

17.11

3.70

0.13

-

1.23

rice hu...

Embodiment 3

[0072] (1) Preparation of high-efficiency expansion clinker and expansion agent for cement concrete

[0073] Limestone, pyrite slag and rice husk ash with a mass ratio of 75:20:5 are crushed and mixed, and are jointly ground by a mill to a fineness of 400m 2 / kg of raw meal powder. The ground raw meal powder was calcined at 1350°C for 30 minutes at this temperature. Immediately after the calcination, the calcined sample was taken out and quenched in the air, and the specific surface area was 200m2 after grinding. 2 / kg of expanded clinker powder for cement concrete.

[0074] Table 6 is the chemical composition (wt.%) of raw material limestone, pyrite slag and rice husk ash

[0075] name

CaO

Fe 2 o 3

Al 2 o 3

SiO 2

SO 3

MgO

C

loss

limestone

54.07

1.72

0.58

0.25

-

0.18

-

43.2

pyrite cinder

6.17

44.80

26.86

17.11

3.70

0.13

-

1.23

rice husk as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com